Difference between revisions of "Aramid fiber"

m (Text replace - "== Authority ==" to "== Sources Checked for Data in Record ==") |

|||

| Line 2: | Line 2: | ||

== Description == | == Description == | ||

| − | A manufactured fiber in which the fiber-forming substance is any long chain synthetic polyamide in which at least 85% of the amide linkages are directly attached to two aromatic rings (Federal Trade Commission definition). Two types of aramids, meta-aramid (e.g., [[Nomex | + | A manufactured fiber in which the fiber-forming substance is any long chain synthetic polyamide in which at least 85% of the amide linkages are directly attached to two aromatic rings (Federal Trade Commission definition). Two types of aramids, meta-aramid (e.g., [[Nomex|Nomex®]]) and para-aramid (e.g., [[Kevlar|Kevlar®]]) are made. Both types of aramid fibers are lightweight and provide extremely high strength. They also have excellent temperature, abrasion and stretch resistance. In addition, meta-aramids are soft and electrically conductive. Para-aramids are stiff, and have greater tenacity and strength than the meta-aramids. However, para-aramids are sensitive to chemicals and will degrade in the presence of acids, alkalis and bleaches. In general, aramids are used in many applications such as bulletproof vests, aerospace construction, protective clothing, high pressure hoses, tires, ropes and high strength honeycomb foams ("HRH 10"). |

[[File:kevlarfiberslarge.jpg|thumb|Aramid fiber]] | [[File:kevlarfiberslarge.jpg|thumb|Aramid fiber]] | ||

Revision as of 14:47, 26 November 2019

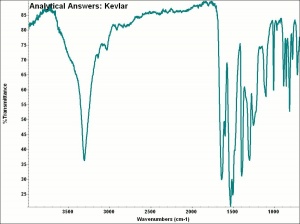

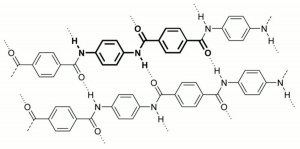

Description

A manufactured fiber in which the fiber-forming substance is any long chain synthetic polyamide in which at least 85% of the amide linkages are directly attached to two aromatic rings (Federal Trade Commission definition). Two types of aramids, meta-aramid (e.g., Nomex®) and para-aramid (e.g., Kevlar®) are made. Both types of aramid fibers are lightweight and provide extremely high strength. They also have excellent temperature, abrasion and stretch resistance. In addition, meta-aramids are soft and electrically conductive. Para-aramids are stiff, and have greater tenacity and strength than the meta-aramids. However, para-aramids are sensitive to chemicals and will degrade in the presence of acids, alkalis and bleaches. In general, aramids are used in many applications such as bulletproof vests, aerospace construction, protective clothing, high pressure hoses, tires, ropes and high strength honeycomb foams ("HRH 10").

Synonyms and Related Terms

aromatic polyamide (full name); aramid fibre; Nomex® [DuPont]; Kevlar® (originally Fiber B) [DuPont]; TeijinConex® [Teijin]; Twaron® [Azko]; Technora® [Teijin]; Fenilon; Arenka®; Kermel; meta-aramid; para-aramid; Aramidfasern (Deut.); fibre aramide (Fr.); fibra de aramida (Esp.); aramide (Ned.)aromatic polyamide (full name); aramid fibre; Nomex® [DuPont]; Kevlar® (originally Fiber B) [DuPont]; TeijinConex® [Teijin]; Twaron® [Azko]; Technora® [Teijin]; Fenilon; Arenka®; Kermel; meta-aramid; para-aramid; Aramidfasern (Deut.); fibre aramide (Fr.); fibra de aramida (Esp.); aramide (Ned.)

Other Properties

Resistant to most organic solvents. Para-aramids are degraded by acids, alkalis and oxidizing agents. Tenacity = 4.2-32.5 g/denier (dry); 3.2-18 (wet); Elongation 3-30% (dry); 4-27% (wet); Moisture regain = 3.5-7.0 %.

| Melting Point | > 410 |

|---|---|

| Density | 1.38-1.45 |

Hazards and Safety

Nonflammable. Degrades in ultraviolet light

Additional Information

° M. Joseph, Introductory Textile Science, Holt Reinhold & Winston, Fort Worth, 1986.

° G.Cook, Handbook of Textile Fibres:II. Man-made Fibres, 5th edition, Merrow Publishing Co., Durham, England, 1984, p. 326

Comparisons

Properties of Synthetic Fibers

Sources Checked for Data in Record

- J.Gordon Cook, Handbook of Textile Fibres:II Man-made Fibres, Merrow Publishing Co. , Durham, England Comment: p.329

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985 Comment: moisture regain = 2-3%

- Marjory L. Joseph, Introductory Textile Science, Holt, Rinehart and Winston, Fort Worth, TX, 1986

- Wikipedia, the free encyclopedia, at http://www.wikipedia.com Comment: http://en.wikipedia.org/wiki/Aramid (Accessed Oct. 18, 2005)

- Richard S. Lewis, Hawley's Condensed Chemical Dictionary, Van Nostrand Reinhold, New York, 10th ed., 1993

- Random House, Webster's Encyclopedic Unabridged Dictionary of the English Language, Grammercy Book, New York, 1997

- Meredith Montague, contributed information, 1998

- Theodore J. Reinhart, 'Glossary of Terms', Engineered Plastics, ASM International, 1988

- Website address 1 Comment: www.textileworld.com/categories/9905/fibers/html