Difference between revisions of "Azlon fiber"

| (9 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

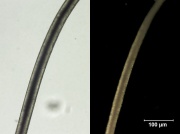

[[File:Azlon 200X BF.POL.jpg|thumb|Azlon fiber]] | [[File:Azlon 200X BF.POL.jpg|thumb|Azlon fiber]] | ||

== Description == | == Description == | ||

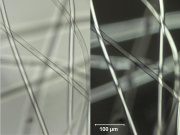

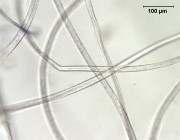

| − | + | [[File:Vicara 200X BF.POL.jpg|thumb|Vicara fibers]] | |

Azlon is the generic name for a manufactured fiber in which the fiber-forming substance is composed of any regenerated naturally occurring [[protein|proteins]] (Federal Trade Commission definition). By the turn of the 19th century, methods for regenerated protein had been developed but they resulted in a hard, brittle material. It was not until the 1930s, that an Italian chemist, Antonio Ferretti developed a successful method to make regenerated protein fibers. Lanital was first sold in 1936. Azlon fibers were made from peanuts, corn, [[zein|zein]], cottonseeds, and [[casein|casein]]. The fibers were often blended with [[wool|wool]], [[cotton|cotton]], or synthetics for weaving. Fabrics made from azlon were soft, lustrous and had a good hand. They dyed well and were used as a silk substitutes by many European fashion designers. Azlon, however, has been replaced by other synthetic fibers, because it was weak when wet and was susceptible to microbiological growths. | Azlon is the generic name for a manufactured fiber in which the fiber-forming substance is composed of any regenerated naturally occurring [[protein|proteins]] (Federal Trade Commission definition). By the turn of the 19th century, methods for regenerated protein had been developed but they resulted in a hard, brittle material. It was not until the 1930s, that an Italian chemist, Antonio Ferretti developed a successful method to make regenerated protein fibers. Lanital was first sold in 1936. Azlon fibers were made from peanuts, corn, [[zein|zein]], cottonseeds, and [[casein|casein]]. The fibers were often blended with [[wool|wool]], [[cotton|cotton]], or synthetics for weaving. Fabrics made from azlon were soft, lustrous and had a good hand. They dyed well and were used as a silk substitutes by many European fashion designers. Azlon, however, has been replaced by other synthetic fibers, because it was weak when wet and was susceptible to microbiological growths. | ||

See also [[casein%20fiber|casein fiber]], [[zein%20fiber|zein fiber]], and [[Chinon|Chinon]]. | See also [[casein%20fiber|casein fiber]], [[zein%20fiber|zein fiber]], and [[Chinon|Chinon]]. | ||

| − | + | * For Azlon fiber identification and photomicrographs, see http://cameo.mfa.org/wiki/Category:FRIL:_Azlon | |

| − | [[File: | + | [[File:Lanital 200X BF.jpg|thumb|Lanital fibers]] |

| − | |||

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

| Line 13: | Line 12: | ||

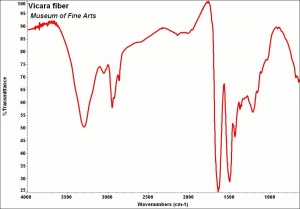

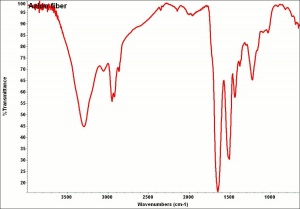

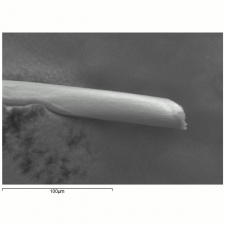

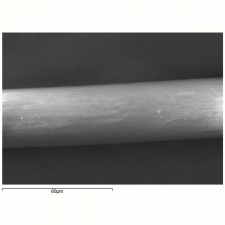

[[[SliderGallery rightalign|Vicara fiber.jpg~FTIR|Azlonfiberkj1.jpg~FTIR|azlon500m.jpg~SEM|azlon1000m.jpg~SEM]]] | [[[SliderGallery rightalign|Vicara fiber.jpg~FTIR|Azlonfiberkj1.jpg~FTIR|azlon500m.jpg~SEM|azlon1000m.jpg~SEM]]] | ||

| + | == Risks == | ||

| − | == | + | Combustible. Unpleasant odor when wet. Fibers very weak when wet. |

| + | == Physical and Chemical Properties == | ||

Insoluble in dilute acids, hydrogen peroxide and most organic solvents. Affected by alkalis. | Insoluble in dilute acids, hydrogen peroxide and most organic solvents. Affected by alkalis. | ||

| Line 37: | Line 38: | ||

| 14% | | 14% | ||

|} | |} | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

== Comparisons == | == Comparisons == | ||

| − | [[media: | + | [[media:download_file_46.pdf|Properties of Synthetic Fibers]] |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | == Resources and Citations == | |

| − | |||

| − | |||

| + | * Joan Kiplinger 'Vintage Fabrics' at [http://www.fabrics.net/joan103.asp Fabrics.net] | ||

| − | + | * G.Cook, ''Handbook of Textile Fibres:II. Man-made Fibres'', 5th edition, Merrow Publishing Co., Durham, England, 1984. | |

* Rosalie Rosso King, ''Textile Identification, Conservation, and Preservation'', Noyes Publications, Park Ridge, NJ, 1985 | * Rosalie Rosso King, ''Textile Identification, Conservation, and Preservation'', Noyes Publications, Park Ridge, NJ, 1985 | ||

Latest revision as of 12:29, 5 December 2020

Description

Azlon is the generic name for a manufactured fiber in which the fiber-forming substance is composed of any regenerated naturally occurring proteins (Federal Trade Commission definition). By the turn of the 19th century, methods for regenerated protein had been developed but they resulted in a hard, brittle material. It was not until the 1930s, that an Italian chemist, Antonio Ferretti developed a successful method to make regenerated protein fibers. Lanital was first sold in 1936. Azlon fibers were made from peanuts, corn, Zein, cottonseeds, and Casein. The fibers were often blended with Wool, Cotton, or synthetics for weaving. Fabrics made from azlon were soft, lustrous and had a good hand. They dyed well and were used as a silk substitutes by many European fashion designers. Azlon, however, has been replaced by other synthetic fibers, because it was weak when wet and was susceptible to microbiological growths.

See also Casein fiber, Zein fiber, and Chinon.

- For Azlon fiber identification and photomicrographs, see http://cameo.mfa.org/wiki/Category:FRIL:_Azlon

Synonyms and Related Terms

azlon fibre; zein fiber; casein fiber; Lanital [Snia Viscosa, Italy]; Aralac; Chinon [Toyobo Co., Japan]; Ardil [England]; Merinova [Italy]; Fibrolane [Courtaulds, England]; Vicara [Virginian-Carolina Chemical];

Risks

Combustible. Unpleasant odor when wet. Fibers very weak when wet.

Physical and Chemical Properties

Insoluble in dilute acids, hydrogen peroxide and most organic solvents. Affected by alkalis.

Filaments are smooth. Cross sections = circular, bean-shaped.

| Density | 1.25-1.3 |

|---|---|

| Diameter | 20-30 micrometers |

| Tenacity | 0.9-1.1 g/denier (dry); 0.3-0.6 (wet) |

| Elongation | 60-70% |

| Moisture regain | 14% |

Comparisons

Properties of Synthetic Fibers

Resources and Citations

- Joan Kiplinger 'Vintage Fabrics' at Fabrics.net

- G.Cook, Handbook of Textile Fibres:II. Man-made Fibres, 5th edition, Merrow Publishing Co., Durham, England, 1984.

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985

- Marjory L. Joseph, Introductory Textile Science, Holt, Rinehart and Winston, Fort Worth, TX, 1986

- Random House, Webster's Encyclopedic Unabridged Dictionary of the English Language, Grammercy Book, New York, 1997

- Thomas Gregory, The Condensed Chemical Dictionary, Reinhold Publishing, New York, 3rd ed., 1942

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 640