Difference between revisions of "Cellulose acetate"

m (Text replace - "== Authority ==" to "== Sources Checked for Data in Record ==") |

|||

| Line 2: | Line 2: | ||

== Description == | == Description == | ||

| − | A general name for thermoplastic polymers composed of the acetic acid ester of cellulose. Cellulose acetate was first developed by Schutzenberger in 1865. In 1908 it was introduced as safety film by Eastman Kodak and | + | A general name for thermoplastic polymers composed of the acetic acid ester of cellulose. Cellulose acetate was first developed by Schutzenberger in 1865. In 1908, it was introduced as safety film by Eastman Kodak because it showed similar properties and uses to cellulose nitrate but was less flammable. By 1910, with production by Dreyfus in France, cellulose acetate began replacing cellulose nitrate film. Cellulose acetate fibers were first manufactured commercially in Great Britain in 1919 (Celanese®). |

| + | |||

| + | Cellulose acetate is made by chemically modifying cotton [[linters|linters]] and/or purified [[wood pulp]] with [[sulfuric acid]], then acetylated with [[acetic acid]] and [[acetic anhydride]]. The first portion of the reaction produces cellulose triacetate; cellulose diacetate is obtained by partial hydrolysis to replace some of the acetyl groups with hydroxyl groups. Cellulose diacetate is commonly called acetate while the cellulose triacetate is called triacetate. Plasticizers, such as glycol phthalate, tributyl phosphate, dimethyl phthalate, diethyl phthalate or [[dibutyl phthalate]] are added to cellulose acetate to increase flexibility. The plasticizers also help to make the material less flammable (Richardson 2014). | ||

See also [[acetate fiber]], [[cellulose diacetate]], [[cellulose triacetate]], and [[cellulose acetate butyrate]]. | See also [[acetate fiber]], [[cellulose diacetate]], [[cellulose triacetate]], and [[cellulose acetate butyrate]]. | ||

| Line 11: | Line 13: | ||

Examples: Celanese [British Celanese]; Kodacel [Eastman Kodak]; Tenite; Similoid; | Examples: Celanese [British Celanese]; Kodacel [Eastman Kodak]; Tenite; Similoid; | ||

| − | |||

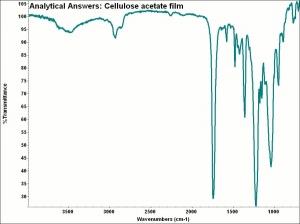

[[[SliderGallery rightalign|aaiCELLACET.jpg~FTIR]]] | [[[SliderGallery rightalign|aaiCELLACET.jpg~FTIR]]] | ||

| + | == Applications == | ||

| + | * Photographic film and animations cels | ||

| + | * transparent sheeting | ||

| + | * Lacquers and coatings | ||

| + | * Fibers (see acetate fiber) | ||

| − | == | + | == Personal Risks == |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | == Collection Risks == | |

| + | Degradation produces volatile acetic acid. Plasticizer migration may result in oily or sticky surfaces. | ||

| − | + | == Physical and Chemical Properties == | |

| − | + | * Resistant to dilute alkalis and dry-cleaning solvents. | |

| − | + | * Degrades in acids and concentrated alkalis. | |

| − | + | * Soluble in acetone, phenol and chloroform. | |

| − | + | * Produces tiny sparks when burnt and gives faint odor of acetic acid. | |

| − | + | * Plasticized cellulose acetate: refractive index = 1.48-1.51 | |

| − | + | * Melting Point = 232 | |

| − | + | * Density = 1.25-1.35 | |

| − | + | * Refractive Index = 1.48 (pure) | |

| − | |||

| − | |||

== Hazards and Safety == | == Hazards and Safety == | ||

| − | + | ||

Burns readily. | Burns readily. | ||

Revision as of 11:39, 5 July 2020

Description

A general name for thermoplastic polymers composed of the acetic acid ester of cellulose. Cellulose acetate was first developed by Schutzenberger in 1865. In 1908, it was introduced as safety film by Eastman Kodak because it showed similar properties and uses to cellulose nitrate but was less flammable. By 1910, with production by Dreyfus in France, cellulose acetate began replacing cellulose nitrate film. Cellulose acetate fibers were first manufactured commercially in Great Britain in 1919 (Celanese®).

Cellulose acetate is made by chemically modifying cotton Linters and/or purified Wood pulp with Sulfuric acid, then acetylated with Acetic acid and Acetic anhydride. The first portion of the reaction produces cellulose triacetate; cellulose diacetate is obtained by partial hydrolysis to replace some of the acetyl groups with hydroxyl groups. Cellulose diacetate is commonly called acetate while the cellulose triacetate is called triacetate. Plasticizers, such as glycol phthalate, tributyl phosphate, dimethyl phthalate, diethyl phthalate or Dibutyl phthalate are added to cellulose acetate to increase flexibility. The plasticizers also help to make the material less flammable (Richardson 2014).

See also Acetate fiber, Cellulose diacetate, Cellulose triacetate, and Cellulose acetate butyrate.

Synonyms and Related Terms

CA; acétate de cellulose (Fr.); Celluloseacetat (Deut.); acetato de celulosa (Esp.); acetato di cellulosa (It.); acetato de celulose (Port.); safety film; secondary acetate

Examples: Celanese [British Celanese]; Kodacel [Eastman Kodak]; Tenite; Similoid;

Applications

- Photographic film and animations cels

- transparent sheeting

- Lacquers and coatings

- Fibers (see acetate fiber)

Personal Risks

Collection Risks

Degradation produces volatile acetic acid. Plasticizer migration may result in oily or sticky surfaces.

Physical and Chemical Properties

- Resistant to dilute alkalis and dry-cleaning solvents.

- Degrades in acids and concentrated alkalis.

- Soluble in acetone, phenol and chloroform.

- Produces tiny sparks when burnt and gives faint odor of acetic acid.

- Plasticized cellulose acetate: refractive index = 1.48-1.51

- Melting Point = 232

- Density = 1.25-1.35

- Refractive Index = 1.48 (pure)

Hazards and Safety

Burns readily.

Degrades in sunlight, heat, and high humidity. Resistant to insects, slowly degraded by microorganisms.

Additional Information

Museum Handbook, Part 1. Museums Collections. Web Edition. Appendix M. Management of Cellulose Nitrate and Cellulose Acetate Films, NPS, 2001. http://www.cr.nps.gov/museum/publications/MHI/AppendM.pdf

Comparisons

Physical Properties for Selected Thermoplastic Resins

General Characteristics of Polymers

Sources Checked for Data in Record

- R. J. Gettens, G.L. Stout, Painting Materials, A Short Encyclopaedia, Dover Publications, New York, 1966

- Ralph Mayer, A Dictionary of Art Terms and Techniques, Harper and Row Publishers, New York, 1969 (also 1945 printing)

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985

- Michael McCann, Artist Beware, Watson-Guptill Publications, New York City, 1979

- C.V.Horie, Materials for Conservation, Butterworth-Heineman, London, 1997

- Matt Roberts, Don Etherington, Bookbinding and the Conservation of Books: a Dictionary of Descriptive Terminology, U.S. Government Printing Office, Washington DC, 1982

- Pam Hatchfield, Pollutants in the Museum Environment, Archetype Press, London, 2002

- Marjory L. Joseph, Introductory Textile Science, Holt, Rinehart and Winston, Fort Worth, TX, 1986

- John S. Mills, Raymond White, The Organic Chemistry of Museum Objects, Butterworth Heineman, London, 2nd ed., 1994

- M.Kaufman, The First Century of Plastics, The Plastics and Rubber Institute, London, 1963

- Wikipedia, the free encyclopedia, at http://www.wikipedia.com Comment: http://en.wikipedia.org/wiki/Cellulose_acetate (Accessed Jan. 6 2006) - gives following dates: resin-1865, film-1934, fiber-1924

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p.169

- Richard S. Lewis, Hawley's Condensed Chemical Dictionary, Van Nostrand Reinhold, New York, 10th ed., 1993

- Book and Paper Group, Paper Conservation Catalog, AIC, 1984, 1989

- Van Nostrand's Scientific Encyclopedia, Douglas M. Considine (ed.), Van Nostrand Reinhold, New York, 1976

- Random House, Webster's Encyclopedic Unabridged Dictionary of the English Language, Grammercy Book, New York, 1997

- The American Heritage Dictionary or Encarta, via Microsoft Bookshelf 98, Microsoft Corp., 1998

- Sharon Blank, An introduction to plastics and rubbers in collections, Studies in Conservation, 35, 53-63, 1990

- Theodore J. Reinhart, 'Glossary of Terms', Engineered Plastics, ASM International, 1988

- Art and Architecture Thesaurus Online, http://www.getty.edu/research/tools/vocabulary/aat/, J. Paul Getty Trust, Los Angeles, 2000

- Website address 1 Comment: History of Plastics: www.nswpmith.com.au/historyofplastics.html