Chemical wood pulp

Description

Paper pulp made from chemically treated wood fibers. Chemical pulp is produced by treating debarked, ground wood or chips with strong solutions to dissolve the lignin and hemicellulose. The undissolved cellulose fibers are washed, rinsed, sometimes bleached, then used to produce paper. The three main types of solutions used to make chemical pulp are:

- alkaline: Sodium sulfide followed by caustic soda solution (Kraft process),

- alkaline: caustic soda Soda process,

- acid: acid bisulfite (Sulfite process).

Synonyms and Related Terms

chemical pulp; woodfree pulp

Other Properties

Produces a pale blue-violet to red violet response to iodine-zinc chloride solution. Graff "C" stain can be used to distinguish types of chemical pulping and bleaching.

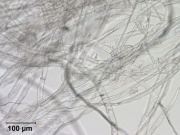

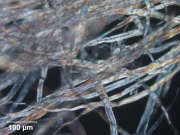

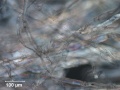

Additional Images

Authority

- Encyclopedia Britannica, http://www.britannica.com Comment: "Paper Pulp." Encyclopædia Britannica. 2003. 11 Sep, 2003 .

- Random House, Webster's Encyclopedic Unabridged Dictionary of the English Language, Grammercy Book, New York, 1997

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 574

- The Dictionary of Paper, American Paper Institute, New York, Fourth Edition, 1980

- E.J.LaBarre, Dictionary and Encyclopedia of Paper and Paper-making, Swets & Zeitlinger, Amsterdam, 1969

- Boise Cascade Paper Group, The Paper Handbook, Boise Cascade, Portland OR, 1989

- J. H. Graff "Color Atlas for Fiber Identification" The Institute of Paper Chemistry, Appleton, WI, 1940.

- Matt Roberts, Don Etherington, Bookbinding and the Conservation of Books: a Dictionary of Descriptive Terminology, U.S. Government Printing Office, Washington DC, 1982

- TAPPI Official Standard T401 om-08. Fiber analysis of paper and paperboard. 2008. http://www.tappi.org/Downloads/Test-Methods/UNTITLED-0104T401pdf.aspx

- Silvie Turner, Which Paper?, Design Press, New York, 1991