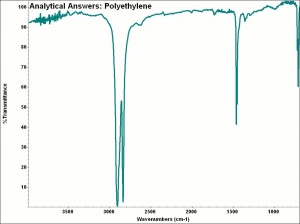

Polyethylene

Description

A thermoplastic polymerin the polyolefin familywith a base formula of (CH-n). Ethylene was first polymerized in 1933 by ICI in England and was commercially released as Alkathene in 1939. In 1954, Karl Ziegler developed a process for high molecular weight polyethylene that allowed it to be spun into fibers, molded into durable but flexible forms and cast as tough thin sheets. Polyethylene made by the original process is now called Low density polyethylene (LDPE; density = 0.92, melting pt=110-120 C) because if has extensive branching resulting in a softer, more flexible product with low tensile strength. Polymers made by the later Ziegler or Phillips processes are called High density polyethylene or (HDPE; density=0.95-0.96, melting pt=130-138C) because they lave a low degree of branching resulting in high tensile strength. HDPR tends to have a longer lifespan that LDPE. In general, polyethylenes are translucent waxy polymers with good impact strength that are widely used for packaging, coatings, liners, plastic sheets, wire coatings, underwater cables, containers, waste bags, toys, and squeeze bottles. Small amounts of additives (antioxidants, light stabilizers, slip agents, antistatic agents, flame retardants, pigments, etc.) are typically added to the final products. Polyethylene is recyclable and many products, such as Tyvek, contain the recycled polymer.

Synonyms and Related Terms

PE; polietileno (Esp.); polythylne (Fr.); polietilene (It.); polietileno (Port.); polyolefin; polythene; alkathene

Examples: Volara; Ethafoam; Tyvek [DuPont]; Hi Core [Matra Plast]; Tupperware; Lennite; Corrulite;

Other Properties

Soluble in xylene, trichlorobenzene, decane at room temperature and most chlorinated and aromatic solvents when gently heated. Insoluble in acetone, diethyl ether.

Burns with yellow flame and blue center that smells like paraffin.

Floats on water.

| Composition | [-CH2-]n |

|---|---|

| CAS | 9002-88-4 |

| Melting Point | 110-138 |

| Density | 0.92-0.96 |

| Refractive Index | 1.52 |

Hazards and Safety

Degraded by ultraviolet light and sulfur containing pollutants.

May contain additives (such as antioxidant BHT) that can migrate to adjacent materials and cause staining.

Dow Corning: MSDS

Comparisons

Physical Properties for Selected Thermoplastic Resins

General Characteristics of Polymers

Additional Images

Sources Checked for Data in Record

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 304

- Marjorie Shelley, The Care and Handling of Art Objects, The Metropolitan Museum, New York, 1987

- Richard S. Lewis, Hawley's Condensed Chemical Dictionary, Van Nostrand Reinhold, New York, 10th ed., 1993

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985

- Matt Roberts, Don Etherington, Matt Roberts, Don Etherington, Bookbinding and the Conservation of Books: a Dictionary of Descriptive Terminology, U.S. Government Printing Office, Washington DC, 1982

- Pam Hatchfield, Pollutants in the Museum Environment, Archetype Press, London, 2002

- Thomas C. Jester (ed.), Twentieth-Century Building Materials, McGraw-Hill Companies, Washington DC, 1995

- Random House, Webster's Encyclopedic Unabridged Dictionary of the English Language, Grammercy Book, New York, 1997

- M.Kaufman, The First Century of Plastics, The Plastics and Rubber Institute, London, 1963

- Art and Architecture Thesaurus Online, http://www.getty.edu/research/tools/vocabulary/aat/, J. Paul Getty Trust, Los Angeles, 2000

- Website address 1 Comment: www.nswpmith.com.au/historyofplastics.html

- The Dictionary of Art, Grove's Dictionaries Inc., New York, 1996 Comment: "Plastics"

- Sharon Blank, An introduction to plastics and rubbers in collections, Studies in Conservation, 35, 53-63, 1990