Difference between revisions of "Polyethylene terephthalate"

(→Risks) |

|||

| Line 12: | Line 12: | ||

== Risks == | == Risks == | ||

| − | * Difficult to ignite | + | * Difficult to ignite; self-extinguishing |

* Burns with a shiny, yellow-orange, sooty flame. | * Burns with a shiny, yellow-orange, sooty flame. | ||

| − | * | + | * Low impact strength. |

| + | * Easily degrades in UV light | ||

* AM Polymer: [http://ampolymer.com/SDS/PolyethyleneTerephthalateSDS.html SDS} | * AM Polymer: [http://ampolymer.com/SDS/PolyethyleneTerephthalateSDS.html SDS} | ||

| + | |||

==Physical and Chemical Properties== | ==Physical and Chemical Properties== | ||

Revision as of 13:16, 18 September 2023

Description

A type of polyester made by condensing Ethylene glycol and Terephthalic acid. In 1951, polyethylene terephthalate (PET) became the first commercially marketed polyester. It was sold as Dacron® in the U.S. and as Terylene in Great Britain. PET is a semicrystalline, thermoplastic polymer that is extremely durable and dimensionally stable. It is resistant to abrasion, chemicals. PET is used to make Mylar® and other strong moisture-resistant films used in packaging, photographs, x-rays and audio/visual tapes. Since 1977, PET has been widely used in food containers, especially for carbonated beverages. Recycled PET is used as fiberfill and in cast resins, such as boat hulls and shower units.

Synonyms and Related Terms

PET; polyester; tereftalato de polietilenglicol (Esp.); poli (tereftalato de etieno) (Esp.); polyéthylène terephthalate (Fr.); polietilene tereftalato (It.); tereftalato de polietileno (Port.); polyethylene glycol terephthalate

Examples: Dacron® [DuPont]; Fortrel®; Mylar® [DuPont]; Melinex® [DuPont]; Terylene [ICI]; Ertalyte® [Quadrant]; Eastar® {Eastman]; Impet® [Ticona]; Terphane® [Terphane]; Crimplene; Diolen; Grilene; Tergal [Tergal Industries];Terital; Tetoron; Trevira® [Trevira ex Höchst]

Risks

- Difficult to ignite; self-extinguishing

- Burns with a shiny, yellow-orange, sooty flame.

- Low impact strength.

- Easily degrades in UV light

- AM Polymer: [http://ampolymer.com/SDS/PolyethyleneTerephthalateSDS.html SDS}

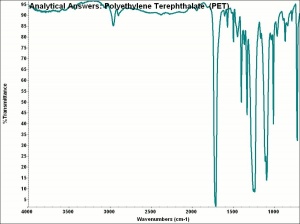

Physical and Chemical Properties

Resistant to cold acids, weak alkalis, bleach and most organic solvents. Degrades in strong alkalis, strong hot acids, cresol. Tenacity = 2.8-5.2; Elongation = 19-30%; Moisture regain = 0.4%

| Melting Point | 250-260 |

|---|---|

| Density | 1.36-1.41 g/ml |

| Refractive Index | 1.54, 1.72 |

Comparisons

Physical Properties for Selected Thermoplastic Resins

General Characteristics of Polymers

Resources and Citations

- Pam Hatchfield, Pollutants in the Museum Environment, Archetype Press, London, 2002

- Marjory L. Joseph, Introductory Textile Science, Holt, Rinehart and Winston, Fort Worth, TX, 1986

- Van Nostrand's Scientific Encyclopedia, Douglas M. Considine (ed.), Van Nostrand Reinhold, New York, 1976

- Identification of Textile Materials, The Textile Institute, Manchester, England, 1985

- Theodore J. Reinhart, 'Glossary of Terms', Engineered Plastics, ASM International, 1988