Difference between revisions of "Poplar"

| Line 26: | Line 26: | ||

== Physical and Chemical Properties == | == Physical and Chemical Properties == | ||

| − | * Diverse trees | + | * Diverse trees from from 15-50 m tall and tend to be slender |

* Bark: smooth and white to greenish or gray | * Bark: smooth and white to greenish or gray | ||

* Flower are long, drooping catkins | * Flower are long, drooping catkins | ||

| Line 32: | Line 32: | ||

* Rays = fine | * Rays = fine | ||

* Density = 22-35 ppcf | * Density = 22-35 ppcf | ||

| + | * Anisotropic | ||

| + | * Responds to humidity and can act as buffer | ||

| + | * Medium density wood with low-bending, shock resistance, stiffness and compression values | ||

| + | |||

| + | ==Working Properties== | ||

| + | Poplar is one of the softest hardwoods available. It is very easily worked and machined. Poplar is suitable for turnings. Poplar is also suitable for boring and takes mortising well. Yellow Poplar is not suitable for moulding production but is suitable for carving. Poplar takes glue well. Mechanical fasteners all work fairly well, however screws and staples hold much better than nails. Because of its softness and character sanding and finishing poplar can take more effort than other wood species. Finish application can raise the grain requiring additional coats of primer or finish with sanding required between coats. If heartwood is present in the stock it can leach color into water-based finishes resulting in uneven finish color. This heartwood is not structurally inferior. Poplar takes stain and varnish well. Poplar is suitable for steam bending. | ||

| + | |||

| + | ==Forms and Sizes== | ||

| + | Comes in typical lumber dimensions and can be cut down to any size | ||

== Resources and Citations == | == Resources and Citations == | ||

Revision as of 14:57, 25 October 2020

Description

Any of several hardwood trees from the genus Populus. The trees are in the willow family and are found in temperate regions of the Northern hemisphere. In general, poplar is a soft, lightweight wood that is easy to work. The wood has a fine, uniform grain but it is prone to warping. It is primarily used for paneling, light construction, packing crates, cardboard and paper pulp. Poplar was frequently used in Italian panel paintings and for sculptures in southern Germany in the late Gothic period.

Common types of poplar trees include:

1) Balsam poplar (Populus balsamifer or Populus tac a ma haca)

2) Cottonwood (Populus deltoides)

3) English poplar or black poplar (Populus nigra)

4) Gray poplar (Populus x canescens)

5) White poplar (Populus alba)

6) Trembling poplar or Aspen (Populus tremula)

7) Yellow poplar or Tulip tree (Liriodendron tulipifera)

Synonyms and Related Terms

peuplier (Fr.), chopo (Esp.); álamo (Esp.); choupo branco (Port.); pioppo (It.)

Physical and Chemical Properties

- Diverse trees from from 15-50 m tall and tend to be slender

- Bark: smooth and white to greenish or gray

- Flower are long, drooping catkins

- Annual rings = well-defined

- Rays = fine

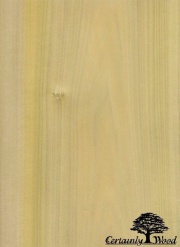

- Density = 22-35 ppcf

- Anisotropic

- Responds to humidity and can act as buffer

- Medium density wood with low-bending, shock resistance, stiffness and compression values

Working Properties

Poplar is one of the softest hardwoods available. It is very easily worked and machined. Poplar is suitable for turnings. Poplar is also suitable for boring and takes mortising well. Yellow Poplar is not suitable for moulding production but is suitable for carving. Poplar takes glue well. Mechanical fasteners all work fairly well, however screws and staples hold much better than nails. Because of its softness and character sanding and finishing poplar can take more effort than other wood species. Finish application can raise the grain requiring additional coats of primer or finish with sanding required between coats. If heartwood is present in the stock it can leach color into water-based finishes resulting in uneven finish color. This heartwood is not structurally inferior. Poplar takes stain and varnish well. Poplar is suitable for steam bending.

Forms and Sizes

Comes in typical lumber dimensions and can be cut down to any size

Resources and Citations

- Alden Identification Services, Microscopic Wood Identification: Link

- Schoch, W., Heller, I., Schweingruber, F.H., Kienast, F., 2004:Wood anatomy of central European Species: White Poplar, Populus alba L.

- RexLumber: Link DC hardwood supplier that has extensive hardwood operations on East Coast

- American Hardwood Information Center: Link

- R. J. Gettens, G.L. Stout, Painting Materials, A Short Encyclopaedia, Dover Publications, New York, 1966

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 629

- Hermann Kuhn, Conservation and Restoration of Works of Art and Antiquities, Butterworths, London, 1986

- F. H. Titmuss, Commercial Timbers of the World, The Technical Press Ltd., London, 1965 Comment: 25-35 ppcf

- Dictionary of Building Preservation, Ward Bucher, ed., John Wiley & Sons, Inc., New York City, 1996

- Pam Hatchfield, Pollutants in the Museum Environment, Archetype Press, London, 2002

- Encyclopedia Britannica, http://www.britannica.com Comment: "poplar" [Accessed November 7, 2001].

- CRC Handbook of Chemistry and Physics, Robert Weast (ed.), CRC Press, Boca Raton, Florida, v. 61, 1980 Comment: density=22-31 ppcf (0.35-0.50 g/cm3)