Difference between revisions of "Saran fiber"

(username removed) |

(username removed) |

||

| Line 2: | Line 2: | ||

== Description == | == Description == | ||

| − | A generic name for manufactured fibers in which the fiber-forming substance is any long chain synthetic polymer composed of at least 80% by weight of vinylidene chloride units (Federal Trade Commission definition). Originally a trademark material first sold by Dow Chemical in 1940, saran is now a commonly used name for films and fibers made from [http://cameo.mfa.org/materials/fullrecord.asp?name=polyvinylidene | + | A generic name for manufactured fibers in which the fiber-forming substance is any long chain synthetic polymer composed of at least 80% by weight of vinylidene chloride units (Federal Trade Commission definition). Originally a trademark material first sold by Dow Chemical in 1940, saran is now a commonly used name for films and fibers made from [http://cameo.mfa.org/materials/fullrecord.asp?name=polyvinylidene%20chloride polyvinylidene chloride]. Saran fibers have good chemical resistance to acids and alkalis and do not lose their strength in sunlight. They are resistant to water and insects. In addition, saran fabrics do not tend to retain dirt and are easy to clean. Saran fabrics are heavy. They have been used for home furnishings, automobile upholstery, belts, sports bags and shoes. Saran, however, is expensive and most applications now use olefins or other high-performance fibers. |

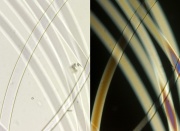

| − | [[File: | + | [[File:Saran 200X BF.POL2.jpg|thumb|Saran fibers]] |

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

| − | saran fibre; poly(vinylidene chloride) fiber; polyvinylidene chloride; | + | saran fibre; poly(vinylidene chloride) fiber; polyvinylidene chloride; Saran® [Ametek]; Piviacid; Velon [Firestone Industrial Plastics]; Permalon [Pierce Plastics]; Enjay® |

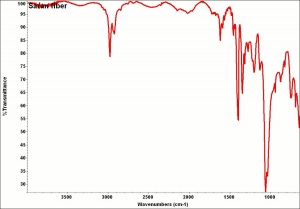

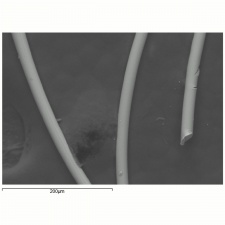

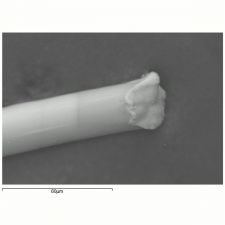

| − | [[[SliderGallery rightalign|saran250m.jpg~SEM|saran1000m.jpg~SEM]]] | + | [[[SliderGallery rightalign|Saranfiberkj1.jpg~FTIR|saran250m.jpg~SEM|saran1000m.jpg~SEM]]] |

== Other Properties == | == Other Properties == | ||

| Line 34: | Line 34: | ||

== Additional Information == | == Additional Information == | ||

| − | M. Joseph, ''Introductory Textile Science'', Holt Reinhold & Winston, Fort Worth, 1986. | + | ° M. Joseph, ''Introductory Textile Science'', Holt Reinhold & Winston, Fort Worth, 1986. ° G.Cook, ''Handbook of Textile Fibres:II. Man-made Fibres'', 5th edition, Merrow Publishing Co., Durham, England, 1984. p.484. |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

== Authority == | == Authority == | ||

| − | * | + | * G.S.Brady, ''Materials Handbook'', McGraw-Hill Book Co., New York, 1971 Comment: p. 850 |

| − | * | + | * Hoechst Celanese Corporation, ''Dictionary of Fiber & Textile Technology'' (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990 |

| − | * | + | * Rosalie Rosso King, ''Textile Identification, Conservation, and Preservation'', Noyes Publications, Park Ridge, NJ, 1985 |

| − | * | + | * Marjory L. Joseph, ''Introductory Textile Science'', Holt, Rinehart and Winston, Fort Worth, TX, 1986 |

| − | * | + | * J.Gordon Cook, ''Handbook of Textile Fibres:II Man-made Fibres'', Merrow Publishing Co. , Durham, England |

* Wikipedia, the free encyclopedia, at http://www.wikipedia.com Comment: http://en.wikipedia.org/wiki/Saran_%28plastic%29 (Accessed Nov. 9, 2005) | * Wikipedia, the free encyclopedia, at http://www.wikipedia.com Comment: http://en.wikipedia.org/wiki/Saran_%28plastic%29 (Accessed Nov. 9, 2005) | ||

Revision as of 07:24, 24 July 2013

Description

A generic name for manufactured fibers in which the fiber-forming substance is any long chain synthetic polymer composed of at least 80% by weight of vinylidene chloride units (Federal Trade Commission definition). Originally a trademark material first sold by Dow Chemical in 1940, saran is now a commonly used name for films and fibers made from polyvinylidene chloride. Saran fibers have good chemical resistance to acids and alkalis and do not lose their strength in sunlight. They are resistant to water and insects. In addition, saran fabrics do not tend to retain dirt and are easy to clean. Saran fabrics are heavy. They have been used for home furnishings, automobile upholstery, belts, sports bags and shoes. Saran, however, is expensive and most applications now use olefins or other high-performance fibers.

Synonyms and Related Terms

saran fibre; poly(vinylidene chloride) fiber; polyvinylidene chloride; Saran® [Ametek]; Piviacid; Velon [Firestone Industrial Plastics]; Permalon [Pierce Plastics]; Enjay®

Other Properties

Resistant to acids, alkalis, sunlight, bleaches. May be damaged by ketones, carbon tetrachloride, alcohol, perchloroethylene. Resistant to insects and bacteria. Fibers are transparent and smooth. Cross section = circular. Tenacity = 0.7-2.4 g/denier (dry or wet); Elongation = 15-30% (dry or wet); Moisture regain = 0.1-1.0%

Burns with green flame producing pungent odor and evolving HCl.

| Melting Point | 160-177 |

|---|---|

| Density | 1.1-1.7 |

Hazards and Safety

Softens at 115 C and lose strength at 99C.

Combustible but self-extinguishing. May release acids when heated.

Additional Information

° M. Joseph, Introductory Textile Science, Holt Reinhold & Winston, Fort Worth, 1986. ° G.Cook, Handbook of Textile Fibres:II. Man-made Fibres, 5th edition, Merrow Publishing Co., Durham, England, 1984. p.484.

Authority

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 850

- Hoechst Celanese Corporation, Dictionary of Fiber & Textile Technology (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985

- Marjory L. Joseph, Introductory Textile Science, Holt, Rinehart and Winston, Fort Worth, TX, 1986

- J.Gordon Cook, Handbook of Textile Fibres:II Man-made Fibres, Merrow Publishing Co. , Durham, England

- Wikipedia, the free encyclopedia, at http://www.wikipedia.com Comment: http://en.wikipedia.org/wiki/Saran_%28plastic%29 (Accessed Nov. 9, 2005)