Difference between revisions of "Tyvek"

| (25 intermediate revisions by the same user not shown) | |||

| Line 2: | Line 2: | ||

== Description == | == Description == | ||

| − | [DuPont] Discovered in 1955, this spunbonded, olefin product was trademarked in 1967. | + | [DuPont] Discovered in 1955, this spunbonded, olefin product was trademarked in 1967. Tyvek® is 100% [[high density polyethylene|high density polyethylene]] without any fillers or binders. The fine, white, continuous filaments (0.5-10 microns) are bonded by heat and pressure to form a dimensionally stable, opaque sheet. Tyvek® is chemically stable, lightweight, durable, strong, lint-free, and acid-free. The paper/fabric is resistant to wetting, but it allows transmission of moisture and vapors. It is widely used as a wear resistant, tear resistant, waterproof paper for banners, maps, and envelopes. Applications also include filtration, packaging, bookcovers, interleaving, clean room clothing, protective garments, and carpet backing. Tyvek® is commonly seen as a protective barrier in new housing construction. In museums, the high-strength wrapping material is used a soft, lint-free, waterproof liner in packing crates and display cases. It is available in stiff (Type 10), soft (Type 14) and perforated (Type 16) forms [http://www.paccin.org/content.php?62-Materials (PACCIN)]. |

[[File:681_2DS_7.jpg|thumb|Tyvek disposable articles]] | [[File:681_2DS_7.jpg|thumb|Tyvek disposable articles]] | ||

| Line 9: | Line 9: | ||

Tyvek@; Tyvek Hardwrap; Tyvek Softwrap; Crate liner | Tyvek@; Tyvek Hardwrap; Tyvek Softwrap; Crate liner | ||

| − | == | + | == Applications== |

| − | + | * Support for textiles | |

| + | * Non-abrasive, tear-resistant envelopes and media sleeves | ||

| + | * Moisture proof liner for cases and crates | ||

| + | * Cover foam pads or line cavities in contour cut foam | ||

| + | * Light-blocking and form-fitting dust covers | ||

| + | * Soft Tyvek® used to make filled bags/snakes to stabilize objects during transport | ||

| + | |||

| + | == Risks == | ||

Degraded by [[Freon]], [[pine oil]], [[Turpentine (oil)|turpentine]], [[dichloromethane]], [[mineral spirits]], [[ligroin]], [[kerosene]], [[toluene]]. | Degraded by [[Freon]], [[pine oil]], [[Turpentine (oil)|turpentine]], [[dichloromethane]], [[mineral spirits]], [[ligroin]], [[kerosene]], [[toluene]]. | ||

| − | + | Tyvek® is degraded by direct exposure to sunlight. Tyvek may generate static electricity unless treated with antistatic agents. | |

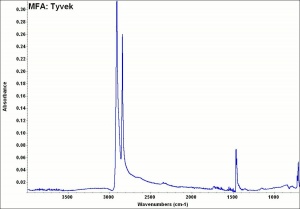

| + | [[[SliderGallery rightalign|MFA- Tyvek.jpg~FTIR]]] | ||

| + | |||

| + | == Physical and Chemical Properties == | ||

| − | + | Resistant to acids, alkalis and most organic solvents. Fibers are 0.5-10 microns. Chemical resistant. Neutral pH. Waterproof, acid-free, lint-free, resistant to mold, mildew, and insects. | |

| − | |||

| − | |||

| − | + | Shrinks at 118 <sup>o</sup>C. Melting point = 135 <sup>o</sup>C. Maintains toughness and flexibility down to -73 <sup>o</sup>C. | |

| + | |||

| + | Dimensional stability depends on fiber thickness. Lighter weights may elongate up to 25% before breaking. | ||

| + | |||

| + | == Working Properties == | ||

| + | |||

| + | Type 10= paper-like, hard structure, area-bonded, smooth pattern, stiff | ||

| + | |||

| + | Type 14= fabric-like, soft structure, point-bonded, embossed pattern, flexible | ||

| − | + | Tyvek® is tear resistant but is easily cut with scissors or a knife. Water vapor can pass Tyvek, but liquid water cannot. | |

| + | Tyvek® can be bonded by ultrasonic welding or dielectric bonding. Heat sealing causes puckering as it often bonds to itself. | ||

| − | + | Dupont recommends water-based adhesives (starch, dextrin, animal glues, PVAC) over any synthetic solvent-based adhesives. | |

| − | |||

| − | |||

| − | == | + | == Forms/Sizes == |

| + | Tyvek® sheets are available as 30", 36” and 60” wide rolls in length up to 100 yds long. Thicknesses can range from 6.6 mils (1025=hard, 1443R=soft), 7.3 mills (1020=hard) and 7.6 mils (14M=soft) | ||

| − | + | Various sizes of pre-made folders, media sleeves, envelopes and expansion envelopes. | |

| − | |||

| − | |||

== Additional Information == | == Additional Information == | ||

| Line 41: | Line 55: | ||

== Sources Checked for Data in Record == | == Sources Checked for Data in Record == | ||

| + | * Rachael Perkins Arenstein, Lisa Goldberg, and Eugenie Milroy, ‘Support and Rehousing for Collection Storage’ In ‘Preventive Conservation: Collection Storage’ Lisa Elkin and Christopher A. Norris (eds.), Society for the Preservation of Natural History Collections, New York. 2019. | ||

| + | |||

* Preparation, Art Handling, Collections Care Information Network [http://www.paccin.org/content.php?62-Materials (PACCIN)] | * Preparation, Art Handling, Collections Care Information Network [http://www.paccin.org/content.php?62-Materials (PACCIN)] | ||

| − | * | + | * Rosalie Rosso King, ''Textile Identification, Conservation, and Preservation'', Noyes Publications, Park Ridge, NJ, 1985 |

| − | * | + | * Book and Paper Group, ''Paper Conservation Catalog'', AIC, 1984, 1989 |

| − | * | + | * Pam Hatchfield, ''Pollutants in the Museum Environment'', Archetype Press, London, 2002 |

| − | * | + | * Meredith Montague, contributed information, 1998 |

| − | * Website address 1, | + | * Website address 1, Comment: AMOL reCollections Glossary -http://amol.org.au/recollections/7/c/htm |

| − | [[Category:Materials database]] [[Category: | + | [[Category:Materials database]] [[Category:MWG]] [[Category:PACCIN]] |

Revision as of 10:34, 27 November 2019

Description

[DuPont] Discovered in 1955, this spunbonded, olefin product was trademarked in 1967. Tyvek® is 100% High density polyethylene without any fillers or binders. The fine, white, continuous filaments (0.5-10 microns) are bonded by heat and pressure to form a dimensionally stable, opaque sheet. Tyvek® is chemically stable, lightweight, durable, strong, lint-free, and acid-free. The paper/fabric is resistant to wetting, but it allows transmission of moisture and vapors. It is widely used as a wear resistant, tear resistant, waterproof paper for banners, maps, and envelopes. Applications also include filtration, packaging, bookcovers, interleaving, clean room clothing, protective garments, and carpet backing. Tyvek® is commonly seen as a protective barrier in new housing construction. In museums, the high-strength wrapping material is used a soft, lint-free, waterproof liner in packing crates and display cases. It is available in stiff (Type 10), soft (Type 14) and perforated (Type 16) forms (PACCIN).

Synonyms and Related Terms

Tyvek@; Tyvek Hardwrap; Tyvek Softwrap; Crate liner

Applications

- Support for textiles

- Non-abrasive, tear-resistant envelopes and media sleeves

- Moisture proof liner for cases and crates

- Cover foam pads or line cavities in contour cut foam

- Light-blocking and form-fitting dust covers

- Soft Tyvek® used to make filled bags/snakes to stabilize objects during transport

Risks

Degraded by Freon, Pine oil, turpentine, Dichloromethane, Mineral spirits, Ligroin, Kerosene, Toluene.

Tyvek® is degraded by direct exposure to sunlight. Tyvek may generate static electricity unless treated with antistatic agents.

Physical and Chemical Properties

Resistant to acids, alkalis and most organic solvents. Fibers are 0.5-10 microns. Chemical resistant. Neutral pH. Waterproof, acid-free, lint-free, resistant to mold, mildew, and insects.

Shrinks at 118 oC. Melting point = 135 oC. Maintains toughness and flexibility down to -73 oC.

Dimensional stability depends on fiber thickness. Lighter weights may elongate up to 25% before breaking.

Working Properties

Type 10= paper-like, hard structure, area-bonded, smooth pattern, stiff

Type 14= fabric-like, soft structure, point-bonded, embossed pattern, flexible

Tyvek® is tear resistant but is easily cut with scissors or a knife. Water vapor can pass Tyvek, but liquid water cannot.

Tyvek® can be bonded by ultrasonic welding or dielectric bonding. Heat sealing causes puckering as it often bonds to itself.

Dupont recommends water-based adhesives (starch, dextrin, animal glues, PVAC) over any synthetic solvent-based adhesives.

Forms/Sizes

Tyvek® sheets are available as 30", 36” and 60” wide rolls in length up to 100 yds long. Thicknesses can range from 6.6 mils (1025=hard, 1443R=soft), 7.3 mills (1020=hard) and 7.6 mils (14M=soft)

Various sizes of pre-made folders, media sleeves, envelopes and expansion envelopes.

Additional Information

DuPont: Tyvek Website

Sources Checked for Data in Record

- Rachael Perkins Arenstein, Lisa Goldberg, and Eugenie Milroy, ‘Support and Rehousing for Collection Storage’ In ‘Preventive Conservation: Collection Storage’ Lisa Elkin and Christopher A. Norris (eds.), Society for the Preservation of Natural History Collections, New York. 2019.

- Preparation, Art Handling, Collections Care Information Network (PACCIN)

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985

- Book and Paper Group, Paper Conservation Catalog, AIC, 1984, 1989

- Pam Hatchfield, Pollutants in the Museum Environment, Archetype Press, London, 2002

- Meredith Montague, contributed information, 1998

- Website address 1, Comment: AMOL reCollections Glossary -http://amol.org.au/recollections/7/c/htm