Tyvek

Description

[DuPont] Discovered in 1955, this spunbonded, olefin product was trademarked in 1967. Tyvek® is 100% High density polyethylene without any fillers or binders. The fine, white, continuous filaments (0.5-10 microns) are bonded by heat and pressure to form a dimensionally stable, opaque sheet. Tyvek® is chemically stable, lightweight, durable, strong, lint-free, and acid-free. The paper/fabric is resistant to wetting, but it allows transmission of moisture and vapors. It is widely used as a wear resistant, tear resistant, waterproof paper for banners, maps, and envelopes. Applications also include filtration, packaging, bookcovers, interleaving, clean room clothing, protective garments, and carpet backing. Tyvek® is commonly seen as a protective barrier in new housing construction. In museums, the high-strength wrapping material is used a soft, lint-free, waterproof liner in packing crates and display cases. It is available in stiff (Type 10), soft (Type 14) and perforated (Type 16) forms (PACCIN).

Synonyms and Related Terms

Tyvek@; Tyvek Hardwrap; Tyvek Softwrap; Crate liner

Applications

- Support for textiles

- Non-abrasive, tear-resistant envelopes and media sleeves

- Moisture proof liner for cases and crates

- Cover foam pads or line cavities in contour cut foam

- Light-blocking and form-fitting dust covers

- Soft Tyvek® used to make filled bags/snakes to stabilize objects during transport

Risks

Degraded by Freon, Pine oil, turpentine, Dichloromethane, Mineral spirits, Ligroin, Kerosene, Toluene.

Tyvek® is degraded by direct exposure to sunlight. Tyvek may generate static electricity unless treated with antistatic agents.

DuPont: [Safety Data sheet]

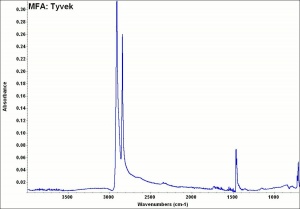

Physical and Chemical Properties

Resistant to acids, alkalis and most organic solvents. Fibers are 0.5-10 microns. Chemical resistant. Neutral pH. Waterproof, acid-free, lint-free, resistant to mold, mildew, and insects.

Shrinks at 118 oC. Melting point = 135 oC. Maintains toughness and flexibility down to -73 oC.

Dimensional stability depends on fiber thickness. Lighter weights may elongate up to 25% before breaking.

Working Properties

Type 10= paper-like, hard structure, area-bonded, smooth pattern, stiff

Type 14= fabric-like, soft structure, point-bonded, embossed pattern, flexible

Tyvek® is tear resistant but is easily cut with scissors or a knife. Water vapor can pass Tyvek, but liquid water cannot.

Tyvek® can be bonded by ultrasonic welding or dielectric bonding. Heat sealing causes puckering as it often bonds to itself.

Dupont recommends water-based adhesives (starch, dextrin, animal glues, PVAC) over any synthetic solvent-based adhesives.

Forms/Sizes

Tyvek® sheets are available as 30", 36” and 60” wide rolls in length up to 100 yds long. Thicknesses can range from 6.6 mils (1025=hard, 1443R=soft), 7.3 mills (1020=hard) and 7.6 mils (14M=soft)

Various sizes of pre-made folders, media sleeves, envelopes and expansion envelopes.

Additional Information

DuPont: Tyvek Website

Resources and Citations

- Rachael Perkins Arenstein, Lisa Goldberg, and Eugenie Milroy, ‘Support and Rehousing for Collection Storage’ In ‘Preventive Conservation: Collection Storage’ Lisa Elkin and Christopher A. Norris (eds.), Society for the Preservation of Natural History Collections, New York. 2019.

- Preparation, Art Handling, Collections Care Information Network (PACCIN)

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985

- Book and Paper Group, Paper Conservation Catalog, AIC, 1984, 1989

- Pam Hatchfield, Pollutants in the Museum Environment, Archetype Press, London, 2002

- Meredith Montague, contributed information, 1998

- AMOL reCollections Glossary -http://amol.org.au/recollections/7/c/htm