Glass fiber

Description

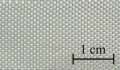

A manufactured fiber composed of thin strands of spun Glass. Thin glass filaments were used for decoration on glass vessels by the Egyptians, Romans and Venetians. By the 18th century, glass fibers were used in imitation feathers and lamp wicks, but the fibers were too short or brittle for use in textiles. In 1893, Edward D. Libbey first made a fabric from long, flexible, continuous fibers obtained from melted glass marbles extruded through spinnerets. Now glass fibers are available as glass wool, chopped strands, scrim, cloth, and tissue. While the individual fibers are brittle, the twisted and plied yarn as well as the woven cloth is strong. Glass fibers can tolerate heat to 450 degrees centigrade without change. They are resistant to light, most chemicals and insects but are broken down by abrasion and folding. Glass fibers are used for filters, insulation, fire proof fabrics, geotextiles, tire cord, and as reinforcements in synthetic resins and Concrete. Although glass fibers are flame resistant, they are only occasionally used in fireproof household furnishings, such as draperies, lampshades, ironing board covers and tablecloths.

Synonyms and Related Terms

glass fibre; fiberglass; fibreglass (Br.); Glasfaser (Deut.); fibra de vidrio (Esp.); fibre de verre (Fr.); laine de verre (Fr.); glasvezel (Ned.); glasfiber (Sven.) fiber glass; silica fiber; quartz fiber; spun glass; Fiberglas [Owens-Corning]; Marglass; Beta; Chemglass; Modiglass; Refrasil [Chemical and Insulating, England]; Avceram [Avtex Fibers]

Risks

- Nonflammable.

- Broken ends of fibers can cause skin irritation.

- The fibers will break in the wash spin cycles and tumbler dryers.

- Orca Composites: SDS

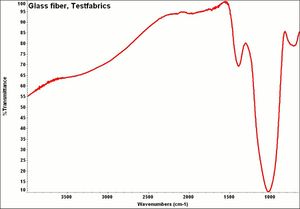

Physical and Chemical Properties

- Unaffected by bleach or organic solvents.

- May be degraded by alkali solutions and strong detergents.

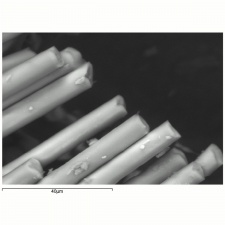

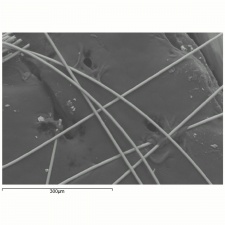

- Fiber is smooth; cross section is circular.

- Diameters= 0.7-16 micrometers

- 100% elastic recovery

- Loses strength above 315C

- Tenacity = 6.0-7.3 g/denier (dry); 3.9-4.7 (wet)

- Elongation = 3-4 % (dry); 2.5-3.5 % (wet)

- Moisture regain =0

- Melting Point = 815 C (softens)

- Density = 2.49-2.54 g/ml

- Refractive Index = 1.541-1.549

Additional Images

Resources and Citations

- M. Joseph, Introductory Textile Science, Holt Reinhold & Winston, Fort Worth, 1986.

- G.Cook, Handbook of Textile Fibres:II. Man-made Fibres, 5th edition, Merrow Publishing Co., Durham, England, 1984.

- Hoechst Celanese Corporation, Hoechst Celanese Corporation, Dictionary of Fiber & Textile Technology (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990

- Rosalie Rosso King, Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985

- Matt Roberts, Don Etherington, Matt Roberts, Don Etherington, Bookbinding and the Conservation of Books: a Dictionary of Descriptive Terminology, U.S. Government Printing Office, Washington DC, 1982

- Identification of Textile Materials, The Textile Institute, Manchester, England, 1985

- Website: 'Can this be glass? The strange story of Fiberglas-the wonder glass of the 20th Century' Owens-Corning, Toledo Ohio, 1939.

- Wikipedia: http://en.wikipedia.org/wiki/Fiberglass (Accessed Feb. 10, 2006)