Viscose rayon

Description

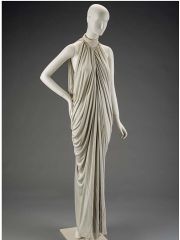

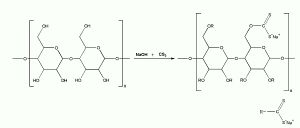

Rayon produced from Cellulose dissolved in Sodium hydroxide, then treated with Carbon disulfide to form an orange viscous solution of cellulose xanthate (Viscose). The process for making viscose was discovered in 1892 by Charles Cross and Edward Bevan in England. Soon after the turn of the century, several companies began manufacturing viscose rayon and it quickly became the most important natural polymer fiber. Viscose has good washability and fair abrasion resistance. It dyes well and has good sunlight resistance. It is dyed with direct dyes at low temperatures. Viscose rayons are used for woven and nonwoven fabrics, rubbers, felts, tire cords, and cellophane.

See also rayon.

Synonyms and Related Terms

cellophane; rayon; viscose; Avtex; regenerated cellulose; artificial silk; wood silk; kuntsilke (Dan.); Kunstseide (Deut.); Viskosefasern (Deut.); viscose (Fr.); rayon viscosa (It.); rayon (Ned., Sven.)

Collection Risks

Links to Oddy Test results posted on AIC Wiki Materials Database Pages for individual materials below

° Khoon Heng show case fabric 65% polyester, 35% viscose tested in 2017

° Khoon Heng show case fabric 65% polyester, 35% viscose tested in 2017

° Khoon Heng show case fabric 65% polyester, 35% viscose tested in 2017

° John Ranger Textiles, Serge 65% polyester, 35% 100% viscose tested in 2016

° Maish Felts, Royal felt: 100% viscose tested in 2010

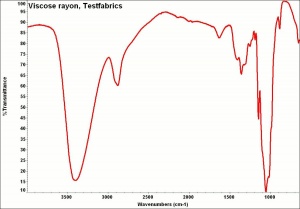

Physical and Chemical Properties

- Insoluble in most organic solvents.

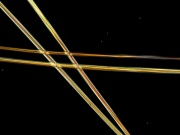

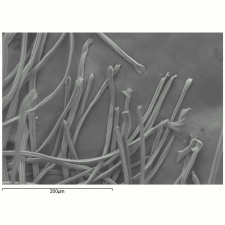

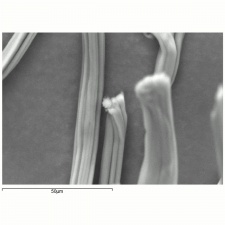

- Viscose fibers have continuous lengthwise striations.

- Cross sections were originally circular with indentations; now may be dog bone or trilobal.

- Tenacity = 2.0-2.6 g/denier (dry); 1.0-1.5 (wet);

- Moisture regain = 11-16.6%;

- Elongation = 15-13%; (dry); 20-40% (wet) ;

- Melting point = 150 C (dec);

- Density = 1.46-1.54 g/ml

- Burns with small flame, incandescent ash and odor of burnt paper.

Comparisons

Properties of Synthetic Fibers

Resources and Citation

- R. J. Gettens, G.L. Stout, Painting Materials, A Short Encyclopaedia, Dover Publications, New York, 1966

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 654

- Hoechst Celanese Corporation, Dictionary of Fiber & Textile Technology (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990

- S.R.Trotman, E.R. Trotman, Textile Analysis, J.B. Lippincott Company, Philadelphia, 1932

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985

- The Dictionary of Paper, American Paper Institute, New York, Fourth Edition, 1980

- J.Gordon Cook, Handbook of Textile Fibres:II Man-made Fibres, Merrow Publishing Co. , Durham, England

- History of Plastics at www.nswpmith.com.au/historyofplastics.html

- Wikipedia: http://en.wikipedia.org/wiki/Rayon (Accessed Jan. 15, 2006)

- The American Heritage Dictionary or Encarta, via Microsoft Bookshelf 98, Microsoft Corp., 1998