Common ash

Description

Large, deciduous ash trees, Fraxinus excelsior, that grow throughout the temperate regions of Europe. Varieties include F. excelsior latifolia (weeping ash) and F.excelsior Diversifolia. European ash trees have a dense wood that is tough and elastic with a straight grain and slightly coarse texture. It is moderately durable but susceptible to insect attack. The timber is used for ladders, tool handles, oars, poles, wheels, boats, weapons, furniture, gymnasium equipment, tennis racquets, and hockey sticks.

Synonyms and Related Terms

European ash (Fraxinus excelsior); weeping ash (F. excelsior latifolia); Almindelig Ask (Dan.); Gemeine Esche (Deut.); frêne (Fr.); es (Ned.); ask (Sven.); fresno (Esp.); freixo europeu (Port.); frassino (It.)

Risks

- Unpleasant odor when worked

- Can cause skin irritation

Physical and Chemical Properties

- Tall tree growing to 35 m.

- Bark = gray; new buds are black

- Leaves = compound with 9-13 leaflets with total length of 20-35 cm.

- Fruit = group of winged samara with long narrow seed.

- Density = 40-53 ppcf

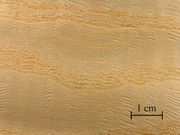

- Heartwood = light to medium brown with some darker streaks; Sapwood is similar and not always demarked

- Durability = Slighly durable to decay; not resistant to insect attack

Paper fiber type: hardwood, ring porous. Using transmitted light microscopy, pulp is identified by vessels with two distinct sizes. Vessels have profuse, small pitting. Perforations are simple. Tyloses and pointed, irregularly shaped vasocentric trachieds are present. Appearance with Graff "C" stain: dark blue, but varies with bleaching. Average dimensions of fibers: length, 0.9mm. 22μm wide. Common pulping method: kraft.

Additional Images

Working Properties

- Produces good results with hand or machine tools.

- Responds well to steam bending.

- Glues, stains, and finishes well.

Resources and Citations

- The Wood Database: European ash

- R.Gale, P.Gasson, N.Hepper, G.Killen, "Wood" in Ancient Egyptian Materials and Technology, P.Nicholson, I.Shaw (eds.), Cambridge University Press, 2000, p. 334-371.

- Schoch, W., Heller, I., Schweingruber, F.H., Kienast, F., 2004:Wood anatomy of central European Species: English Ash,Fraxinus excelsior L.

- R. J. Gettens, G.L. Stout, Painting Materials, A Short Encyclopaedia, Dover Publications, New York, 1966

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 74

- F. H. Titmuss, Commercial Timbers of the World, The Technical Press Ltd., London, 1965

- Gordon Hanlon, contributed information, 1998

- Van Nostrand's Scientific Encyclopedia, Douglas M. Considine (ed.), Van Nostrand Reinhold, New York, 1976

- Random House, Webster's Encyclopedic Unabridged Dictionary of the English Language, Grammercy Book, New York, 1997

- Wikipedia: http://en.wikipedia.org/wiki/European_Ash (Accessed Dec. 9, 2005)

- Marja-Sisko Ilvessalo-Pfäffli. Fiber Atlas: Identification of Papermaking Fibers (Springer Series in Wood Science). Springer, 1995.

- Walter Rantanen. "Fiber ID Course." Integrated Paper Services. June 2013. Lecture.