Difference between revisions of "Gasket Types"

Jump to navigation

Jump to search

| Line 3: | Line 3: | ||

For further information, please see AIC wiki [http://www.conservation-wiki.com/wiki/Using_Gaskets_to_Seal_Exhibit_Cases Gaskets for Exhibit Cases] | For further information, please see AIC wiki [http://www.conservation-wiki.com/wiki/Using_Gaskets_to_Seal_Exhibit_Cases Gaskets for Exhibit Cases] | ||

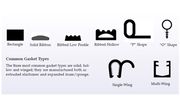

[[File:Gaskets NPS.jpg|thumb|Gasket types<br>Credit: National Park Service]] | [[File:Gaskets NPS.jpg|thumb|Gasket types<br>Credit: National Park Service]] | ||

| − | A compressible material used in an interface to reduce gaps and create tighter fitting joints. Gaskets are held under pressure to reduce leakage, transmission, and or vibration. As such, in museums, gaskets can be used to minimize air exchange between sealed cases and museums, to compensate for alignment irregularities between two edges, and to reduce potential for the transfer of dust, dirt, pollutants and pests. In the past, natural rubber | + | A compressible material used in an interface to reduce gaps and create tighter fitting joints. Gaskets are held under pressure to reduce leakage, transmission, and or vibration. As such, in museums, gaskets can be used to minimize air exchange between sealed cases and museums, to compensate for alignment irregularities between two edges, and to reduce potential for the transfer of dust, dirt, pollutants and pests. In the past, [[natural rubber]], [[paper]], [[metal]], [[felt]], [[asbestos]], and [[cork]] were used for gaskets. More recently, synthetic options, called elastomers have become available. |

| − | Examples of some | + | Examples of some elastomers include: |

* Silicone rubber (dimethyl silicone): most stable of all elastomers, silicone is resistant to high and low temperature ranges, fatigue, most chemicals, oils, oxygen, and ozone. | * Silicone rubber (dimethyl silicone): most stable of all elastomers, silicone is resistant to high and low temperature ranges, fatigue, most chemicals, oils, oxygen, and ozone. | ||

* Cellular silicone sponge (poly-dimethyl siloxane also referred to as PDMS): silicone rubber that has been foamed into a uniform unicellular structure. It has the same characteristics as silicone rubber and is shaped by either extrusion or cutting. | * Cellular silicone sponge (poly-dimethyl siloxane also referred to as PDMS): silicone rubber that has been foamed into a uniform unicellular structure. It has the same characteristics as silicone rubber and is shaped by either extrusion or cutting. | ||

| − | * Ethylene propylene diene monomer (EPDM): resistant to ultraviolet light, ozone, oxidants, heat, compression set and resists the swelling effects of polar chemicals. | + | * [[Ethylene propylene diene|Ethylene propylene diene monomer]] (EPDM): resistant to ultraviolet light, ozone, oxidants, heat, compression set and resists the swelling effects of polar chemicals. |

* Ethylene vinyl acetate closed-cell elastomeric seal (EVA): similar to other elastomers in flexibility and softness, EVA has relatively low resistance to heat and solvents but excellent ozone resistance. | * Ethylene vinyl acetate closed-cell elastomeric seal (EVA): similar to other elastomers in flexibility and softness, EVA has relatively low resistance to heat and solvents but excellent ozone resistance. | ||

| + | * [[Nitrile rubber]]: | ||

| + | * [[Teflon]] (Polytetrafluoroethylene-PTFE): | ||

Revision as of 12:49, 3 December 2020

Description

For further information, please see AIC wiki Gaskets for Exhibit Cases

A compressible material used in an interface to reduce gaps and create tighter fitting joints. Gaskets are held under pressure to reduce leakage, transmission, and or vibration. As such, in museums, gaskets can be used to minimize air exchange between sealed cases and museums, to compensate for alignment irregularities between two edges, and to reduce potential for the transfer of dust, dirt, pollutants and pests. In the past, Natural rubber, Paper, Metal, Felt, Asbestos, and Cork were used for gaskets. More recently, synthetic options, called elastomers have become available.

Examples of some elastomers include:

- Silicone rubber (dimethyl silicone): most stable of all elastomers, silicone is resistant to high and low temperature ranges, fatigue, most chemicals, oils, oxygen, and ozone.

- Cellular silicone sponge (poly-dimethyl siloxane also referred to as PDMS): silicone rubber that has been foamed into a uniform unicellular structure. It has the same characteristics as silicone rubber and is shaped by either extrusion or cutting.

- Ethylene propylene diene monomer (EPDM): resistant to ultraviolet light, ozone, oxidants, heat, compression set and resists the swelling effects of polar chemicals.

- Ethylene vinyl acetate closed-cell elastomeric seal (EVA): similar to other elastomers in flexibility and softness, EVA has relatively low resistance to heat and solvents but excellent ozone resistance.

- Nitrile rubber:

- Teflon (Polytetrafluoroethylene-PTFE):