Difference between revisions of "Modal fiber"

m (Text replace - "== Authority ==" to "== Sources Checked for Data in Record ==") |

|||

| (4 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

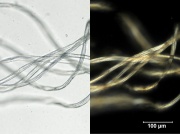

| − | [[File:Tenasco 200X BF.POL.jpg|thumb|Micrographs of Tenasco fibers]] | + | [[File:Tenasco 200X BF.POL.jpg|thumb|Micrographs of Tenasco fibers at 200x (left: transmitted light, right: polarized light]] |

== Description == | == Description == | ||

| − | A generic name for a modified [ | + | A generic name for a modified |

| + | [[rayon%20fiber|rayon]] fiber that has high tenacity and high wet modulus. Modal fibers were initially developed in the 1930s for industrial uses in tires, conveyor belts and hose pipes. Changes in the rayon processing, such as the spin conditions, chemical solutions, and stretching sequences, produced rayon fibers with increased crystallinity, and thus, greater strength. Additional developments in Japan in 1951 by S. Tachikawa led to the production of a modal fiber with high wet modulus called | ||

| + | [[polynosic%20fiber|polynosic]]. Modal fibers are dimensionally stable and do not shrink or get pulled out of shape when wet like many rayons. They are also wear resistant and strong while maintaining a soft, silky feel. Modal fibers have found a wide variety of uses in clothing, outerwear and household furnishings. They are often blended with | ||

| + | [[cotton|cotton]], | ||

| + | [[wool|wool]], or | ||

| + | [[synthetic%20fiber|synthetic fibers]]. | ||

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

| Line 10: | Line 15: | ||

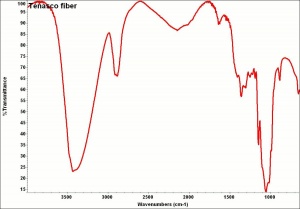

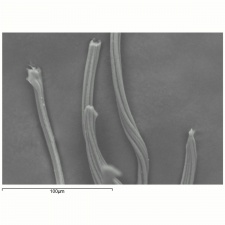

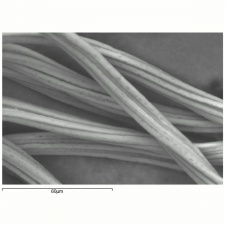

[[[SliderGallery rightalign|Tenascofiberkj1.jpg~FTIR|tenasco500m.jpg~SEM|tenasco1000m.jpg~SEM]]] | [[[SliderGallery rightalign|Tenascofiberkj1.jpg~FTIR|tenasco500m.jpg~SEM|tenasco1000m.jpg~SEM]]] | ||

| − | == | + | == Physical and Chemical Properties == |

| − | Tenacity = 3 - 5 g/denier | + | *Tenacity = 3 - 5 g/denier |

| + | *Elongation = 6-14% (dry); 8-20 % (wet) | ||

| + | *Fiber is smooth; some have striations | ||

| + | *Cross section is circular or bean shaped. | ||

| + | *Density = 1.52-1.54 | ||

| − | + | == Resources and Citations == | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

* J.Gordon Cook, ''Handbook of Textile Fibres:I Natural Fibres'', Merrow Publishing Co. , Durham, England, 1984 | * J.Gordon Cook, ''Handbook of Textile Fibres:I Natural Fibres'', Merrow Publishing Co. , Durham, England, 1984 | ||

Latest revision as of 08:34, 27 September 2022

Description

A generic name for a modified rayon fiber that has high tenacity and high wet modulus. Modal fibers were initially developed in the 1930s for industrial uses in tires, conveyor belts and hose pipes. Changes in the rayon processing, such as the spin conditions, chemical solutions, and stretching sequences, produced rayon fibers with increased crystallinity, and thus, greater strength. Additional developments in Japan in 1951 by S. Tachikawa led to the production of a modal fiber with high wet modulus called polynosic. Modal fibers are dimensionally stable and do not shrink or get pulled out of shape when wet like many rayons. They are also wear resistant and strong while maintaining a soft, silky feel. Modal fibers have found a wide variety of uses in clothing, outerwear and household furnishings. They are often blended with Cotton, Wool, or synthetic fibers.

Synonyms and Related Terms

modal fibre (Br.); HWM rayon; Tenasco [Courtaulds]; Vincel [Courtaulds]; Avril [Avtex Fibers]; Moynel [Courtaulds]; modal

Physical and Chemical Properties

- Tenacity = 3 - 5 g/denier

- Elongation = 6-14% (dry); 8-20 % (wet)

- Fiber is smooth; some have striations

- Cross section is circular or bean shaped.

- Density = 1.52-1.54

Resources and Citations

- J.Gordon Cook, Handbook of Textile Fibres:I Natural Fibres, Merrow Publishing Co. , Durham, England, 1984

- Identification of Textile Materials, The Textile Institute, Manchester, England, 1985