Difference between revisions of "Nylon 4,6"

Jump to navigation

Jump to search

| Line 4: | Line 4: | ||

See [[nylon%20fiber|nylon fiber]]. | See [[nylon%20fiber|nylon fiber]]. | ||

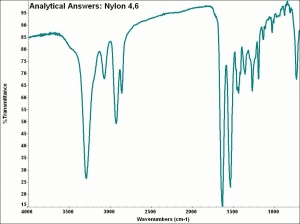

| − | + | [[[SliderGallery rightalign|aaiNYLON-46.jpg~FTIR]]] | |

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

Stanyl | Stanyl | ||

| − | + | ==Physical and Chemical Properties== | |

| − | |||

| − | == | ||

| − | |||

| − | |||

| − | + | * Tenacity = 9.5 g/denier | |

| − | + | * Melting Point = 300 | |

| − | + | * Density = 1.18 | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | == | + | ==Resources and Citations== |

* Marjory L. Joseph, ''Introductory Textile Science'', Holt, Rinehart and Winston, Fort Worth, TX, 1986 | * Marjory L. Joseph, ''Introductory Textile Science'', Holt, Rinehart and Winston, Fort Worth, TX, 1986 | ||

Latest revision as of 13:57, 19 October 2022

Description

Nylon 4,6 is made by polymerizing 1,4-diaminobutane with adipic acid. Nylon 4,6 was introduced in 1984 as the fiber Stanyl. It is similar in most properties to nylon 6 and 6,6, but it has better dimensional stability. It is most often used in industrial applications.

See Nylon fiber.

Synonyms and Related Terms

Stanyl

Physical and Chemical Properties

- Tenacity = 9.5 g/denier

- Melting Point = 300

- Density = 1.18

Resources and Citations

- Marjory L. Joseph, Introductory Textile Science, Holt, Rinehart and Winston, Fort Worth, TX, 1986