Difference between revisions of "Plastic"

| Line 1: | Line 1: | ||

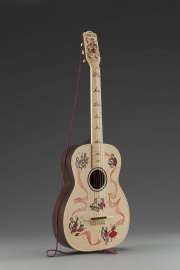

| − | [[File:2001.421-SC71632.jpg|thumb| | + | [[File:2001.421-SC71632.jpg|thumb|Italian guitar<br>MFA# 2001.421]] |

== Description == | == Description == | ||

| − | + | [[File:2004.2149-SC181327.jpg|thumb|Crocheted plastic bowl<br>MFA# 2004.2149]] | |

A general term for any natural or synthetic organic material that can be shaped and molded to form a product that retains its given shape. Natural plastics include [[natural%20resin|tree resins]], [[beeswax|beeswax]], [[gutta-percha|gutta-percha]], [[horn|horn]], and [[clay|clay]]. Synthetic plastics were first made in the 19th century. [[celluloid|Celluloid]], patented in 1870, was the first to achieve commercial success. Plastics are used as substitutes for glass, metal and wood. They are classified as : | A general term for any natural or synthetic organic material that can be shaped and molded to form a product that retains its given shape. Natural plastics include [[natural%20resin|tree resins]], [[beeswax|beeswax]], [[gutta-percha|gutta-percha]], [[horn|horn]], and [[clay|clay]]. Synthetic plastics were first made in the 19th century. [[celluloid|Celluloid]], patented in 1870, was the first to achieve commercial success. Plastics are used as substitutes for glass, metal and wood. They are classified as : | ||

| − | + | * [[thermoplastic|Thermoplastic]] - can be heated to soften then cooled to harden without changing its basic properties. Thermoplastic polymers have a linear structure, can often creep or defor under stress and are usually soluble at room temperature. Examples are: [[acetal%20resin|polyacetal]], as well as some [[acrylic%20resin|acrylics]], [[cellulose%20ester|cellulose esters]], [[fluorocarbon|fluorocarbons]], [[nylon%20resin|nylons]], [[polycarbonate|polycarbonate]], [[polyethylene|polyethylene]], [[polypropylene|polypropylene]], [[polystyrene|polystyrene]], and [[vinyl%20resin|vinyl resins]]. | |

| − | + | * [[thermoset|Thermoset]] - once cured, it cannot be softened with heat or pressure. Thermoset polymers typically have a crosslinked structure and are insoluble at room temeprature. Examples are: [[epoxy|epoxy]], [[phenolic%20resin|phenolic resin]], as well as some [[polyurethane|polyurethanes]], [[polyester%20resin|polyesters]], [[silicone|silicones]], and [[melamine%20resin|melamine]]. | |

| − | |||

| − | |||

| − | |||

Commercial formulations of plastics are complex. They are composed of the base polymer whose physical properties are determined by its specific molecular weight, degree of polymerizations and chemical structure ( i.e., liniear, branched, or cross-linked (Shashoua 2008). Then, these properties are modified are modidifed by various numbers and combinations of additives, such as [[plasticizer|plasticizers]], [[ultraviolet absorber|UV absorbers]], [[stabilizer|heat stabilizers]], [[antioxidant|antioxidants]], [[colorant|colorants]], slip agent and [[Filler|fillers]] (Williams 2019). Once the correct mixture is obtained,, the plastic can extruded, cast, molded or blown to create a variety of product forms, including including solids (e.g., [[fabric|fabrics]], [[Foam|foams]], sheets, [[Rod|rods]], [[Plastic tubing|tubing]], containers) or liquids (e.g., [[Adhesive|adhesives]], [[consolidant|consolidants]], [[sealant|sealants]]). | Commercial formulations of plastics are complex. They are composed of the base polymer whose physical properties are determined by its specific molecular weight, degree of polymerizations and chemical structure ( i.e., liniear, branched, or cross-linked (Shashoua 2008). Then, these properties are modified are modidifed by various numbers and combinations of additives, such as [[plasticizer|plasticizers]], [[ultraviolet absorber|UV absorbers]], [[stabilizer|heat stabilizers]], [[antioxidant|antioxidants]], [[colorant|colorants]], slip agent and [[Filler|fillers]] (Williams 2019). Once the correct mixture is obtained,, the plastic can extruded, cast, molded or blown to create a variety of product forms, including including solids (e.g., [[fabric|fabrics]], [[Foam|foams]], sheets, [[Rod|rods]], [[Plastic tubing|tubing]], containers) or liquids (e.g., [[Adhesive|adhesives]], [[consolidant|consolidants]], [[sealant|sealants]]). | ||

| Line 19: | Line 16: | ||

* Storage to isolate and separate objects | * Storage to isolate and separate objects | ||

| − | |||

* Dust and light protection | * Dust and light protection | ||

| − | |||

* Gas barrier, for anoxic treatments | * Gas barrier, for anoxic treatments | ||

| − | |||

* Padding, support and glazing | * Padding, support and glazing | ||

| − | |||

* Adhesives, consolidants and sealants | * Adhesives, consolidants and sealants | ||

| Line 31: | Line 24: | ||

Plastics may pose the following general hazards to collections (Williams 2019). | Plastics may pose the following general hazards to collections (Williams 2019). | ||

| − | + | * Emission of volatile compounds (e.g., acids, sulfur compounds) that may be react with or deposit on objects causing corrosion, deposits, or degradataion. | |

| − | + | * Exudation of nonvolatile compounds (e.g., plasticizers, antioxidants) that can produc a bloom, stain, or oily surface. | |

| − | + | * Loss of function (e.g., clarity, cushioning, strength, flexibility) with time due to degradation. | |

| − | |||

| − | |||

| − | |||

== Comparisons == | == Comparisons == | ||

Latest revision as of 14:21, 17 August 2022

Description

A general term for any natural or synthetic organic material that can be shaped and molded to form a product that retains its given shape. Natural plastics include tree resins, Beeswax, Gutta-percha, Horn, and Clay. Synthetic plastics were first made in the 19th century. Celluloid, patented in 1870, was the first to achieve commercial success. Plastics are used as substitutes for glass, metal and wood. They are classified as :

- Thermoplastic - can be heated to soften then cooled to harden without changing its basic properties. Thermoplastic polymers have a linear structure, can often creep or defor under stress and are usually soluble at room temperature. Examples are: polyacetal, as well as some acrylics, cellulose esters, fluorocarbons, nylons, Polycarbonate, Polyethylene, Polypropylene, Polystyrene, and vinyl resins.

- Thermoset - once cured, it cannot be softened with heat or pressure. Thermoset polymers typically have a crosslinked structure and are insoluble at room temeprature. Examples are: Epoxy, Phenolic resin, as well as some polyurethanes, polyesters, silicones, and melamine.

Commercial formulations of plastics are complex. They are composed of the base polymer whose physical properties are determined by its specific molecular weight, degree of polymerizations and chemical structure ( i.e., liniear, branched, or cross-linked (Shashoua 2008). Then, these properties are modified are modidifed by various numbers and combinations of additives, such as plasticizers, UV absorbers, heat stabilizers, antioxidants, colorants, slip agent and fillers (Williams 2019). Once the correct mixture is obtained,, the plastic can extruded, cast, molded or blown to create a variety of product forms, including including solids (e.g., fabrics, foams, sheets, rods, tubing, containers) or liquids (e.g., adhesives, consolidants, sealants).

Synonyms and Related Terms

plástico (Esp.); plastique (Fr.); plastica (It.); plástico (Port.)

Applications

- Storage to isolate and separate objects

- Dust and light protection

- Gas barrier, for anoxic treatments

- Padding, support and glazing

- Adhesives, consolidants and sealants

Collection Risks

Plastics may pose the following general hazards to collections (Williams 2019).

- Emission of volatile compounds (e.g., acids, sulfur compounds) that may be react with or deposit on objects causing corrosion, deposits, or degradataion.

- Exudation of nonvolatile compounds (e.g., plasticizers, antioxidants) that can produc a bloom, stain, or oily surface.

- Loss of function (e.g., clarity, cushioning, strength, flexibility) with time due to degradation.

Comparisons

Physical Properties for Selected Thermoset Resins

Physical Properties for Selected Thermoplastic Resins

General Characteristics of Polymers

Resources and Citations

- R. Scott Williams, ‘Plastic Storage Products’ In ‘Preventive Conservation: Collection Storage’ Lisa Elkin and Christopher A. Norris (eds.), Society for the Preservation of Natural History Collections, New York. 2019

- Yvonne Shashoua, 'Conservation of Plastics: Materials Science, Degradation and Preservation' Butterworth-Heinemann, Oxford, 2008

- Ralph Mayer, A Dictionary of Art Terms and Techniques, Harper and Row Publishers, New York, 1969 (also 1945 printing)

- Theodore J. Reinhart, 'Glossary of Terms', Engineered Plastics, ASM International, 1988

- Hoechst Celanese Corporation, Dictionary of Fiber & Textile Technology (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990

- Dictionary of Building Preservation, Ward Bucher, ed., John Wiley & Sons, Inc., New York City, 1996

- Art and Architecture Thesaurus Online, http://www.getty.edu/research/tools/vocabulary/aat/, J. Paul Getty Trust, Los Angeles, 2000

- Sharon Blank, An introduction to plastics and rubbers in collections, Studies in Conservation, 35, 53-63, 1990

- Tom Rowland, Noel Riley, A-Z Guide to Cleaning, Conserving and Repairing Antiques, Constable and Co., Ltd., London, 1981