Silk

Description

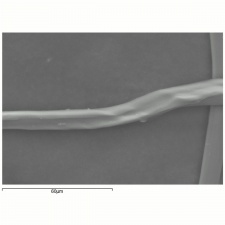

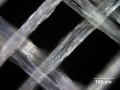

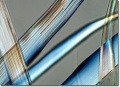

A fine, lustrous natural fiber obtained from the catepillar cocoons of silk moths, such as the domesticated Bombyx mori. Silk moths are native to South and Southeast Asia as well as Northern China (e.g., Antheraea pernyi). According to legend, silk was discovered by Chinese Empress Si-Ling-Shi when a cocoon fell in her tea. China maintained a monopoly on the production of silk fabric for almost 3000 years. The worms were first cultivated in Japan about 195 CE and in Europe about 555 CE. Silk fibers contain a fibroin protein that can be decomposed with acid to form a mixture of amino acids: glycine (41.2 %), alanine (33.0%), serine (16.0 %), and tyrosine (11.4%) (Cook 1984). Microscopically, raw silk appears as two strands that are held together with sericin protein. The Sericin, or gum, is removed by boiling the fibers in soapy water or a dilute alkali. Longitudinal striations appear in the fibers due to wear. Silk readily absorbs soluble salts and is often treated with metal salts, such as tin phosphate/ sodium silicate or tin chloride, to increase its density. A moderately weighted silk contains about 25-50% salt. Weighted silks degrade more rapidly.

See also Wild silk.

Synonyms and Related Terms

si (Chin.); soie (Fr.); silke (Dan., Sven.); Seide (Deut.); seda (Esp., Port.); zijde (Ned.); jedwab (Pol.);

Other Properties

Soluble in hot, strong alkali. Damaged by weak alkali solutions (soap). Unaffected by most organic solvents.

Silk burns readily with an unsteady flame. It smells like burnt hair. The ash is readily crumbled.

For Bombyx mori: Cross section is triangular. Filament length = 250-750 meters long. Moisture regain = 11%; Elongation = 20-25% (normal) and 30% (wet);

| Melting Point | 175 (dec) |

|---|---|

| Density | 1.25-1.34 |

Hazards and Safety

Degraded by sunlight. Decomposed by strong acids. Resistant to moths, bacteria and fungi. Susceptible to carpet beetles.

Additional Information

° G.Cook, Handbook of Textile Fibres:I. Natural Fibres, 5th edition, Merrow Publishing Co., Durham, England, 1984. ° M.Brooks, S.O'Conner, J.McDonnell "The Application of Low-energy X-radiography in the Examination and Investigation of Degraded Historic Silk Textiles" ICOM Preprints, Edinburgh, Vol. II, p.670-79, 1996.

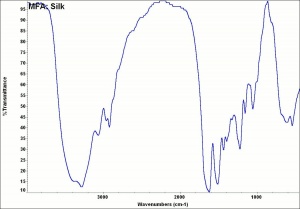

Comparisons

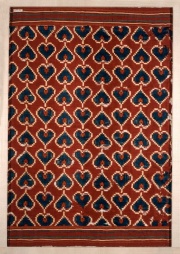

Additional Images

Authority

- Hoechst Celanese Corporation, Dictionary of Fiber & Textile Technology (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990

- S.R.Trotman, E.R. Trotman, Textile Analysis, J.B. Lippincott Company, Philadelphia, 1932

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985

- J.Gordon Cook, Handbook of Textile Fibres:I Natural Fibres, Merrow Publishing Co. , Durham, England, 1984

- Identification of Textile Materials, The Textile Institute, Manchester, England, 1985

- The Dictionary of Art, Grove's Dictionaries Inc., New York, 1996 Comment: "silk"

- Encyclopedia Britannica, http://www.britannica.com Comment: "silk" Encyclopædia Britannica [Accessed November 7, 2001]. .

- Website address 1 Comment: www.fabrics.net

- Wikipedia, the free encyclopedia, at http://www.wikipedia.com Comment: http://en.wikipedia.org/wiki/Silk (Accessed Nov. 29, 2005)

- R. J. Gettens, G.L. Stout, Painting Materials, A Short Encyclopaedia, Dover Publications, New York, 1966

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 721

- Encyclopedia of Archaeology, Glyn E. Daniel, ed., Thomas Y. Crowell Co., New York, 1977

- Hermann Kuhn, Conservation and Restoration of Works of Art and Antiquities, Butterworths, London, 1986