Difference between revisions of "Spruce"

| (3 intermediate revisions by the same user not shown) | |||

| Line 2: | Line 2: | ||

== Description == | == Description == | ||

| − | Any of evergreen several trees from the ''Picea'' family native to northern temperate regions. Spruce trees, in general, have light weight, soft wood with a straight, even grain. The strong wood is easily worked. It is used for musical instrument sounding boards, ladders, cabinets, boxes, [[paper%20pulp|paper pulp]], and [[rayon%20fiber|rayon]]. Spruce wood has no natural resistance to insects, and thus can decay rapidly when allowed to set after logging or when left outside. | + | Any of evergreen several trees from the ''Picea'' family native to northern temperate regions. Spruce trees, in general, have light weight, soft wood with a straight, even grain. The strong wood is easily worked. It is used for musical instrument sounding boards, ladders, cabinets, boxes, [[paper%20pulp|paper pulp]], and [[rayon%20fiber|rayon]]. Spruce wood has no natural resistance to insects, and thus can decay rapidly when allowed to set after logging or when left outside. Even so, spruce trees, have been used to manufacture [[pitch]] thick dark sealant. |

[[File:17.2206-SC29680.jpg|thumb|Triple duct whistle<br>MFA #: 17.2206]] | [[File:17.2206-SC29680.jpg|thumb|Triple duct whistle<br>MFA #: 17.2206]] | ||

| Line 19: | Line 19: | ||

Paper fiber type: Softwood. Using transmitted light microscopy, fibers are identified by the presence of very small, oval, piceoid ray parenchyma pits, 2-4 across. May show cupressiod or taxodiod features. Ray tracheids are non-dentate. Appearance with [[Graff "C" stain]]: varies with pulping method . Average dimensions of fibers: length, 3.4mm width 3.1 μm. Common pulping method: [[kraft process|kraft]] and [[sulfite process|sulfite]]. It is difficult to distinguish spruce fibers from [[hemlock]] fibers in pulp. | Paper fiber type: Softwood. Using transmitted light microscopy, fibers are identified by the presence of very small, oval, piceoid ray parenchyma pits, 2-4 across. May show cupressiod or taxodiod features. Ray tracheids are non-dentate. Appearance with [[Graff "C" stain]]: varies with pulping method . Average dimensions of fibers: length, 3.4mm width 3.1 μm. Common pulping method: [[kraft process|kraft]] and [[sulfite process|sulfite]]. It is difficult to distinguish spruce fibers from [[hemlock]] fibers in pulp. | ||

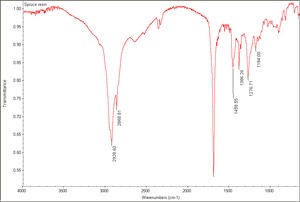

[[[SliderGallery rightalign|Spruce resin.TIF~FTIR(MFA)]]] | [[[SliderGallery rightalign|Spruce resin.TIF~FTIR(MFA)]]] | ||

| − | |||

== Additional Images == | == Additional Images == | ||

| Line 31: | Line 30: | ||

==Resources and Citations== | ==Resources and Citations== | ||

* Wikipedia: https://en.wikipedia.org/wiki/Spruce (accessed October 12, 2020) | * Wikipedia: https://en.wikipedia.org/wiki/Spruce (accessed October 12, 2020) | ||

| − | |||

* Schoch, W., Heller, I., Schweingruber, F.H., Kienast, F., 2004:[http://www.woodanatomy.ch/ Wood anatomy of central European Species]: Common Spruce,Norway Spruce, [http://www.woodanatomy.ch/species.php?code=PCAB Picea abies Karsten] | * Schoch, W., Heller, I., Schweingruber, F.H., Kienast, F., 2004:[http://www.woodanatomy.ch/ Wood anatomy of central European Species]: Common Spruce,Norway Spruce, [http://www.woodanatomy.ch/species.php?code=PCAB Picea abies Karsten] | ||

| − | |||

* G.S.Brady, ''Materials Handbook'', McGraw-Hill Book Co., New York, 1971 Comment: p. 758 | * G.S.Brady, ''Materials Handbook'', McGraw-Hill Book Co., New York, 1971 Comment: p. 758 | ||

| − | |||

* F. H. Titmuss, ''Commercial Timbers of the World'', The Technical Press Ltd., London, 1965 Comment: Picea glauca density = 23-33 ppcf | * F. H. Titmuss, ''Commercial Timbers of the World'', The Technical Press Ltd., London, 1965 Comment: Picea glauca density = 23-33 ppcf | ||

| − | |||

* ''Dictionary of Building Preservation'', Ward Bucher, ed., John Wiley & Sons, Inc., New York City, 1996 | * ''Dictionary of Building Preservation'', Ward Bucher, ed., John Wiley & Sons, Inc., New York City, 1996 | ||

| − | |||

* Northern Pine Manufacturers: air-dry weight = 27pcf | * Northern Pine Manufacturers: air-dry weight = 27pcf | ||

| − | |||

* Marja-Sisko Ilvessalo-Pfäffli. ''Fiber Atlas: Identification of Papermaking Fibers'' (Springer Series in Wood Science). Springer, 1995. | * Marja-Sisko Ilvessalo-Pfäffli. ''Fiber Atlas: Identification of Papermaking Fibers'' (Springer Series in Wood Science). Springer, 1995. | ||

| − | |||

* Walter Rantanen. "Fiber ID Course." Integrated Paper Services. June 2013. Lecture. | * Walter Rantanen. "Fiber ID Course." Integrated Paper Services. June 2013. Lecture. | ||

| − | |||

* Edward Reich, Carlton J. Siegler, ''Consumer Goods: How to Know and Use Them'', American Book Company, New York City, 1937 | * Edward Reich, Carlton J. Siegler, ''Consumer Goods: How to Know and Use Them'', American Book Company, New York City, 1937 | ||

| − | |||

* ''CRC Handbook of Chemistry and Physics'', Robert Weast (ed.), CRC Press, Boca Raton, Florida, v. 61, 1980 Comment: density=30-44 ppcf (0.48-0.70 g/cm3) | * ''CRC Handbook of Chemistry and Physics'', Robert Weast (ed.), CRC Press, Boca Raton, Florida, v. 61, 1980 Comment: density=30-44 ppcf (0.48-0.70 g/cm3) | ||

[[Category:Materials database]] | [[Category:Materials database]] | ||

Latest revision as of 12:58, 18 November 2024

Description

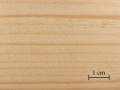

Any of evergreen several trees from the Picea family native to northern temperate regions. Spruce trees, in general, have light weight, soft wood with a straight, even grain. The strong wood is easily worked. It is used for musical instrument sounding boards, ladders, cabinets, boxes, Paper pulp, and rayon. Spruce wood has no natural resistance to insects, and thus can decay rapidly when allowed to set after logging or when left outside. Even so, spruce trees, have been used to manufacture Pitch thick dark sealant.

Synonyms and Related Terms

épicea (Fr.); Schwartztanne (Deut.); picea (Esp.); espruce (Port.); black spruce (Picea mariana); blue spruce (Picea pungens); Engelmann spruce (Picea engelmannii); red spruce (Picea rubens); Sitka spruce (Picea sitchensis); white spruce (Picea glauca)

Note: Commercially the term 'whitewood' is collectively used for spruce wood as well as some pine and firs. The term 'SPF' is accurately used for spruce, fir, or pine.

Physical and Chemical Properties

- Height = large (20-60m) with whorled branches and conical form

- Leaves = unique four-sided needles, shedding every 4-10 years

- Density = 23-44 ppcf; wood has thin-walls and is easily bleached

Paper fiber type: Softwood. Using transmitted light microscopy, fibers are identified by the presence of very small, oval, piceoid ray parenchyma pits, 2-4 across. May show cupressiod or taxodiod features. Ray tracheids are non-dentate. Appearance with Graff "C" stain: varies with pulping method . Average dimensions of fibers: length, 3.4mm width 3.1 μm. Common pulping method: kraft and sulfite. It is difficult to distinguish spruce fibers from Hemlock fibers in pulp.

Additional Images

Resources and Citations

- Wikipedia: https://en.wikipedia.org/wiki/Spruce (accessed October 12, 2020)

- Schoch, W., Heller, I., Schweingruber, F.H., Kienast, F., 2004:Wood anatomy of central European Species: Common Spruce,Norway Spruce, Picea abies Karsten

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 758

- F. H. Titmuss, Commercial Timbers of the World, The Technical Press Ltd., London, 1965 Comment: Picea glauca density = 23-33 ppcf

- Dictionary of Building Preservation, Ward Bucher, ed., John Wiley & Sons, Inc., New York City, 1996

- Northern Pine Manufacturers: air-dry weight = 27pcf

- Marja-Sisko Ilvessalo-Pfäffli. Fiber Atlas: Identification of Papermaking Fibers (Springer Series in Wood Science). Springer, 1995.

- Walter Rantanen. "Fiber ID Course." Integrated Paper Services. June 2013. Lecture.

- Edward Reich, Carlton J. Siegler, Consumer Goods: How to Know and Use Them, American Book Company, New York City, 1937

- CRC Handbook of Chemistry and Physics, Robert Weast (ed.), CRC Press, Boca Raton, Florida, v. 61, 1980 Comment: density=30-44 ppcf (0.48-0.70 g/cm3)