Difference between revisions of "Malleable iron"

(username removed) |

(username removed) |

||

| Line 2: | Line 2: | ||

== Description == | == Description == | ||

| − | [http://cameo.mfa.org/materials/fullrecord.asp?name=White | + | [http://cameo.mfa.org/materials/fullrecord.asp?name=White%20cast%20iron White cast iron] can be converted to malleable iron by decomposing the cementite to form [http://cameo.mfa.org/materials/fullrecord.asp?name=graphite graphite] nodules. To form malleable iron, [http://cameo.mfa.org/materials/fullrecord.asp?name=cast%20iron cast iron] is annealed for 2-3 days at about 800C in an oxygen-free atmosphere, then the temperature is decreased slowly. The [http://cameo.mfa.org/materials/fullrecord.asp?name=iron iron] must be low in [http://cameo.mfa.org/materials/fullrecord.asp?name=carbon carbon] and contain about 1.0 to 1.5% [http://cameo.mfa.org/materials/fullrecord.asp?name=silicon silicon]. The silicon and heat convert any iron carbide to graphite which deposits in nodules. Slight additions of copper accelerates the annealing process. The term malleable iron has also been used to refer to [http://cameo.mfa.org/materials/fullrecord.asp?name=wrought%20iron wrought iron]. |

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

| − | blackheart iron; whiteheart iron; nodular iron; ductile cast iron; wrought iron; fer | + | blackheart iron; whiteheart iron; nodular iron; ductile cast iron; wrought iron; fer malléable (Fr.); Schmiedbares Eisen (Deut.); Schmiedeeisen (Deut.); smeedbaar ijzer (Ned.); ferro fundido dúctil (Port.) |

== Authority == | == Authority == | ||

| Line 12: | Line 12: | ||

* ''Dictionary of Building Preservation'', Ward Bucher, ed., John Wiley & Sons, Inc., New York City, 1996 | * ''Dictionary of Building Preservation'', Ward Bucher, ed., John Wiley & Sons, Inc., New York City, 1996 | ||

| − | * | + | * Website address 1 Comment: Olympus Microscopy Resource Center at http://www.olympusmicro.com/galleries/abramowitz/pages/ductilecastironsmall.html |

* Wikipedia, the free encyclopedia, at http://www.wikipedia.com Comment: http://en.wikipedia.org/wiki/Cast_iron (Accessed Oct. 18, 2005) | * Wikipedia, the free encyclopedia, at http://www.wikipedia.com Comment: http://en.wikipedia.org/wiki/Cast_iron (Accessed Oct. 18, 2005) | ||

| − | * | + | * G.S.Brady, ''Materials Handbook'', McGraw-Hill Book Co., New York, 1971 Comment: p. 489 |

| − | * | + | * Random House, ''Webster's Encyclopedic Unabridged Dictionary of the English Language'', Grammercy Book, New York, 1997 |

[[Category:Materials database]] | [[Category:Materials database]] | ||

Revision as of 06:38, 24 July 2013

Description

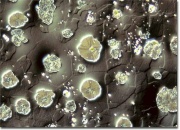

White cast iron can be converted to malleable iron by decomposing the cementite to form graphite nodules. To form malleable iron, cast iron is annealed for 2-3 days at about 800C in an oxygen-free atmosphere, then the temperature is decreased slowly. The iron must be low in carbon and contain about 1.0 to 1.5% silicon. The silicon and heat convert any iron carbide to graphite which deposits in nodules. Slight additions of copper accelerates the annealing process. The term malleable iron has also been used to refer to wrought iron.

Synonyms and Related Terms

blackheart iron; whiteheart iron; nodular iron; ductile cast iron; wrought iron; fer malléable (Fr.); Schmiedbares Eisen (Deut.); Schmiedeeisen (Deut.); smeedbaar ijzer (Ned.); ferro fundido dúctil (Port.)

Authority

- Dictionary of Building Preservation, Ward Bucher, ed., John Wiley & Sons, Inc., New York City, 1996

- Website address 1 Comment: Olympus Microscopy Resource Center at http://www.olympusmicro.com/galleries/abramowitz/pages/ductilecastironsmall.html

- Wikipedia, the free encyclopedia, at http://www.wikipedia.com Comment: http://en.wikipedia.org/wiki/Cast_iron (Accessed Oct. 18, 2005)

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 489

- Random House, Webster's Encyclopedic Unabridged Dictionary of the English Language, Grammercy Book, New York, 1997