Difference between revisions of "Aplix"

| (11 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

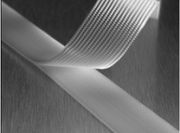

| − | [[File: | + | [[File:Bonded Aplix.jpg|thumb|Aplix, polypropylene]] |

== Description == | == Description == | ||

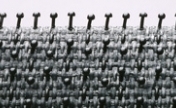

| + | [[File:Mushrooms Aplix.jpg|thumb|Aplix mushrooms]] | ||

| + | [Aplix, Inco] A self-gripping fastening system sold under the name Aplix since 1976. Aplix was originally based on the hook and loop system of the expired Velcro patent. They developed original variations, the first of which was composed of a very soft, unnapped loops. The products are now made on numerous woven and molded patterns composed of nylon, polyester, polypropylene or polyethylene. Inovations include miniaturization, double-sided hooks, mushrooms, and wave patterns. Each system is available with or without pressure-sensitive adhesive on the reverse. | ||

| − | + | * Aplix 800 = nylon base with nylon loops [[file:///C:/Users/Michele/Downloads/APLIX_800.pdf| SDS Link]] | |

| + | * Aplix 804 = polyamide base with polyamide loops [[file:///C:/Users/Michele/Downloads/APLIX_804.pdf| SDS Link]] | ||

| + | * Aplix 810 = polyester base with polyester loops [[file:///C:/Users/Michele/Downloads/APLIX_810.pdf| SDS Link]] | ||

| + | * Aplix N29, N31,N35 and SL100 V2 = polyethylene base and loops | ||

== Applications == | == Applications == | ||

| − | + | ||

* Fasteners for packages, containers and rolled items | * Fasteners for packages, containers and rolled items | ||

| Line 12: | Line 17: | ||

Nylon becomes brittle when exposed to extremely cold temperatures or ultraviolet light. Any pressure sensitive adhesive should be pH neutral and may fail over time. | Nylon becomes brittle when exposed to extremely cold temperatures or ultraviolet light. Any pressure sensitive adhesive should be pH neutral and may fail over time. | ||

| − | == | + | ==Resources and Citations== |

Aplix: [https://www.aplix.com/en/ Website] | Aplix: [https://www.aplix.com/en/ Website] | ||

| Line 18: | Line 23: | ||

| − | + | [[Category:Materials database]][[Category:MWG]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | [[Category:Materials database]] | ||

Latest revision as of 14:33, 27 April 2022

Description

[Aplix, Inco] A self-gripping fastening system sold under the name Aplix since 1976. Aplix was originally based on the hook and loop system of the expired Velcro patent. They developed original variations, the first of which was composed of a very soft, unnapped loops. The products are now made on numerous woven and molded patterns composed of nylon, polyester, polypropylene or polyethylene. Inovations include miniaturization, double-sided hooks, mushrooms, and wave patterns. Each system is available with or without pressure-sensitive adhesive on the reverse.

- Aplix 800 = nylon base with nylon loops [SDS Link]

- Aplix 804 = polyamide base with polyamide loops [SDS Link]

- Aplix 810 = polyester base with polyester loops [SDS Link]

- Aplix N29, N31,N35 and SL100 V2 = polyethylene base and loops

Applications

- Fasteners for packages, containers and rolled items

Risks

Nylon becomes brittle when exposed to extremely cold temperatures or ultraviolet light. Any pressure sensitive adhesive should be pH neutral and may fail over time.

Resources and Citations

Aplix: Website