Difference between revisions of "Salt glaze"

| (2 intermediate revisions by the same user not shown) | |||

| Line 4: | Line 4: | ||

A glassy [[ceramic%20glaze|ceramic glaze]] with a pebbly texture. First made as early as the 12th century in Holland and Germany, salt glazes are produced by a vapor-phase formation of [[sodium%20silicate|sodium silicate]] on the clay surface. An unglazed vessel is placed in the kiln and heated to the optimum temperature (about 1200-1250C), then common salt ([[sodium%20chloride|sodium chloride]]) is thrown into the fire. The salt vaporizes and reacts with steam to produce [[sodium%20oxide|sodium oxide]] which then reacts with the [[silica|silica]] in the clay body to form sodium silicate. Salt glazes are very hard and durable. They have been used on stoneware crocks, masonry units, and terracotta sewer pipes. | A glassy [[ceramic%20glaze|ceramic glaze]] with a pebbly texture. First made as early as the 12th century in Holland and Germany, salt glazes are produced by a vapor-phase formation of [[sodium%20silicate|sodium silicate]] on the clay surface. An unglazed vessel is placed in the kiln and heated to the optimum temperature (about 1200-1250C), then common salt ([[sodium%20chloride|sodium chloride]]) is thrown into the fire. The salt vaporizes and reacts with steam to produce [[sodium%20oxide|sodium oxide]] which then reacts with the [[silica|silica]] in the clay body to form sodium silicate. Salt glazes are very hard and durable. They have been used on stoneware crocks, masonry units, and terracotta sewer pipes. | ||

| − | |||

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

Latest revision as of 12:05, 28 June 2022

Description

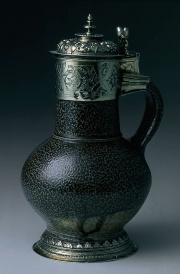

A glassy Ceramic glaze with a pebbly texture. First made as early as the 12th century in Holland and Germany, salt glazes are produced by a vapor-phase formation of Sodium silicate on the clay surface. An unglazed vessel is placed in the kiln and heated to the optimum temperature (about 1200-1250C), then common salt (Sodium chloride) is thrown into the fire. The salt vaporizes and reacts with steam to produce Sodium oxide which then reacts with the Silica in the clay body to form sodium silicate. Salt glazes are very hard and durable. They have been used on stoneware crocks, masonry units, and terracotta sewer pipes.

Synonyms and Related Terms

salt-glaze; demi-émaillage (Fr.); vidrado salino (Port.)

Risks

- Hydrochloric acid is a by-product of the reaction.

Physical and Chemical Properties

Colors can be produced by adding iron oxide (brown), Cobalt oxide (blue), or Manganese oxide (purple).

Resources and Citations

- Ralph Mayer, A Dictionary of Art Terms and Techniques, Harper and Row Publishers, New York, 1969 (also 1945 printing)

- Dictionary of Building Preservation, Ward Bucher, ed., John Wiley & Sons, Inc., New York City, 1996

- Henry Hodges, Artifacts: An Introduction to Early Materials and Technology, Ronald P. Frye, Kingston, Canada, 1988

- Robert Fournier, Illustrated Dictionary of Practical Pottery, Chilton Book Company, Radnor, PA, 1992

- Encyclopedia Britannica, http://www.britannica.com Comment: "salt glaze." Encyclopædia Britannica. 2005. Encyclopædia Britannica Premium Service 4 Feb. 2005 .

- Art and Architecture Thesaurus Online, http://www.getty.edu/research/tools/vocabulary/aat/, J. Paul Getty Trust, Los Angeles, 2000