Difference between revisions of "Polyethylene fiber"

| (3 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | [[File:2004.2114-SC184149.jpg|thumb| | + | [[File:2004.2114-SC184149.jpg|thumb|Coiled newspaper basket<br>MFA# 2004.2114]] |

== Description == | == Description == | ||

A manufactured fiber made from the polymers or copolymers of ethylene. Ethylene was first polymerized in 1933 by ICI in England. In 1954, Karl Ziegler developed a process for higher weight polyethylene that allowed it to be spun into fibers. These fibers, from [[high%20density%20polyethylene|high density polyethylene]], are lightweight, smooth and white with a slightly waxy feel. They are resistant to wear, creases, acids, alkalis, moisture, fungi and insects. Polyethylene fibers do not accept dyes, so they are colored by mixing pigments in the molten polymer prior to extrusion. The fibers slowly degrade in sunlight and can be stained by oils. Polyethylene fibers are used to make waterproof paper (Tyvek®), ropes and fabrics for upholstery for industrial and outdoor applications. | A manufactured fiber made from the polymers or copolymers of ethylene. Ethylene was first polymerized in 1933 by ICI in England. In 1954, Karl Ziegler developed a process for higher weight polyethylene that allowed it to be spun into fibers. These fibers, from [[high%20density%20polyethylene|high density polyethylene]], are lightweight, smooth and white with a slightly waxy feel. They are resistant to wear, creases, acids, alkalis, moisture, fungi and insects. Polyethylene fibers do not accept dyes, so they are colored by mixing pigments in the molten polymer prior to extrusion. The fibers slowly degrade in sunlight and can be stained by oils. Polyethylene fibers are used to make waterproof paper (Tyvek®), ropes and fabrics for upholstery for industrial and outdoor applications. | ||

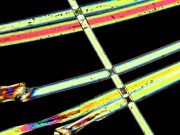

| − | [[File:60 polype Courlene 200X pol.jpg|thumb|Courlene]] | + | [[File:60 polype Courlene 200X pol.jpg|thumb|Courlene at 200x polarized light]] |

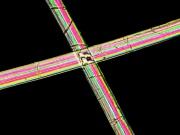

| + | [[File:61 Spectra 900 200X pol.jpg|thumb|Spectra 900 at 200x polarized light]] | ||

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

polyethylene fibre; polyolefin; olefin; high density polyethylene fiber; HDPE fiber; Tyvek® [DuPont]; Reevon; Wynene; Velon; Courlene; Drylene; Spectra® [AlliedSignal]; Dy-neema® [Toyoba/Dyneema];fibras de poliolefinas(Esp.) | polyethylene fibre; polyolefin; olefin; high density polyethylene fiber; HDPE fiber; Tyvek® [DuPont]; Reevon; Wynene; Velon; Courlene; Drylene; Spectra® [AlliedSignal]; Dy-neema® [Toyoba/Dyneema];fibras de poliolefinas(Esp.) | ||

| − | |||

| − | |||

== Risks == | == Risks == | ||

| Line 16: | Line 15: | ||

== Physical and Chemical Properties == | == Physical and Chemical Properties == | ||

| − | Soluble in perchloroethylene (do not dry-clean) and most chlorinated and aromatic solvents when gently heated. Resistant to strong acids, alkalis, bleaches. Cross sections = circular or elliptical. | + | * Soluble in perchloroethylene (do not dry-clean) and most chlorinated and aromatic solvents when gently heated. |

| + | * Resistant to strong acids, alkalis, bleaches. | ||

| + | * Cross sections = circular or elliptical. | ||

| − | For HDPE fibers: Tenacity = 5.0-8.0 g/denier; Moisture regain = | + | For HDPE fibers: |

| + | * Tenacity = 5.0-8.0 g/denier; | ||

| + | * Moisture regain = | ||

{| class="wikitable" | {| class="wikitable" | ||

| Line 26: | Line 29: | ||

|- | |- | ||

! scope="row"| Density | ! scope="row"| Density | ||

| − | | 0.95-0.96 | + | | 0.95-0.96 g/ml |

|- | |- | ||

! scope="row"| Refractive Index | ! scope="row"| Refractive Index | ||

| 1.52 | | 1.52 | ||

|} | |} | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

== Comparisons == | == Comparisons == | ||

| Line 44: | Line 41: | ||

[[media:download_file_79.pdf|Fiber Burn Tests]] | [[media:download_file_79.pdf|Fiber Burn Tests]] | ||

| − | + | ==Resources and Citations== | |

| − | |||

| − | == | ||

* Hoechst Celanese Corporation, ''Dictionary of Fiber & Textile Technology'' (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990 | * Hoechst Celanese Corporation, ''Dictionary of Fiber & Textile Technology'' (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990 | ||

| Line 58: | Line 53: | ||

* J.Gordon Cook, ''Handbook of Textile Fibres:II Man-made Fibres'', Merrow Publishing Co. , Durham, England | * J.Gordon Cook, ''Handbook of Textile Fibres:II Man-made Fibres'', Merrow Publishing Co. , Durham, England | ||

| − | + | * M. Joseph, ''Introductory Textile Science'', Holt Reinhold & Winston, Fort Worth, 1986, p. 135. | |

[[Category:Materials database]] | [[Category:Materials database]] | ||

Latest revision as of 13:47, 4 August 2022

Description

A manufactured fiber made from the polymers or copolymers of ethylene. Ethylene was first polymerized in 1933 by ICI in England. In 1954, Karl Ziegler developed a process for higher weight polyethylene that allowed it to be spun into fibers. These fibers, from High density polyethylene, are lightweight, smooth and white with a slightly waxy feel. They are resistant to wear, creases, acids, alkalis, moisture, fungi and insects. Polyethylene fibers do not accept dyes, so they are colored by mixing pigments in the molten polymer prior to extrusion. The fibers slowly degrade in sunlight and can be stained by oils. Polyethylene fibers are used to make waterproof paper (Tyvek®), ropes and fabrics for upholstery for industrial and outdoor applications.

Synonyms and Related Terms

polyethylene fibre; polyolefin; olefin; high density polyethylene fiber; HDPE fiber; Tyvek® [DuPont]; Reevon; Wynene; Velon; Courlene; Drylene; Spectra® [AlliedSignal]; Dy-neema® [Toyoba/Dyneema];fibras de poliolefinas(Esp.)

Risks

Burns with a heavy, sooty, waxy smoke. Degraded by ultraviolet light and sulfur containing pollutants. May contain additives ( such as antioxidant BHT) that can migrate and cause staining.

Physical and Chemical Properties

- Soluble in perchloroethylene (do not dry-clean) and most chlorinated and aromatic solvents when gently heated.

- Resistant to strong acids, alkalis, bleaches.

- Cross sections = circular or elliptical.

For HDPE fibers:

- Tenacity = 5.0-8.0 g/denier;

- Moisture regain =

| Melting Point | 130-138 |

|---|---|

| Density | 0.95-0.96 g/ml |

| Refractive Index | 1.52 |

Comparisons

Properties of Synthetic Fibers

Resources and Citations

- Hoechst Celanese Corporation, Dictionary of Fiber & Textile Technology (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985

- Identification of Textile Materials, The Textile Institute, Manchester, England, 1985

- Fairchild's Dictionary of Textiles, Phyllis G.Tortora, Robert S. Merkel (eds.), Fairchild Publications, New York City, 7th edition, 1996

- J.Gordon Cook, Handbook of Textile Fibres:II Man-made Fibres, Merrow Publishing Co. , Durham, England

- M. Joseph, Introductory Textile Science, Holt Reinhold & Winston, Fort Worth, 1986, p. 135.