Difference between revisions of "Polypropylene fiber"

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

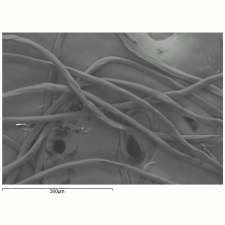

[[File:polypropylenelarge.jpg|thumb|Polypropylene fiber]] | [[File:polypropylenelarge.jpg|thumb|Polypropylene fiber]] | ||

== Description == | == Description == | ||

| − | + | [[File:polypropylenefiberslarge.jpg|thumb|Polypropylene fiber]] | |

A manufactured fiber made from the polymers or copolymers of [[polypropylene|polypropylene]]. In 1954, Giulio Natta (Milan Polytechnic, Italy) polymerized propylene and by 1957 polypropylene fibers were being commercially produced by Montecatini Societa Generale (Italy). Polypropylene fibers are lightweight, smooth and white with a slightly waxy feel. They are resistant to wear, crushing, acids, alkalis, moisture, fungi, and insects. Olefin fibers slowly degrade in sunlight and can be stained by oils. Polypropylene fibers are used to make rope, fishing nets, sewing threads, diaper covers, indoor-outdoor carpeting, artificial grass, upholstery fabrics, and stay-dry clothing. They are also used for geotextiles fabrics, pavement repair, roofing felts, and artificial ski slopes. | A manufactured fiber made from the polymers or copolymers of [[polypropylene|polypropylene]]. In 1954, Giulio Natta (Milan Polytechnic, Italy) polymerized propylene and by 1957 polypropylene fibers were being commercially produced by Montecatini Societa Generale (Italy). Polypropylene fibers are lightweight, smooth and white with a slightly waxy feel. They are resistant to wear, crushing, acids, alkalis, moisture, fungi, and insects. Olefin fibers slowly degrade in sunlight and can be stained by oils. Polypropylene fibers are used to make rope, fishing nets, sewing threads, diaper covers, indoor-outdoor carpeting, artificial grass, upholstery fabrics, and stay-dry clothing. They are also used for geotextiles fabrics, pavement repair, roofing felts, and artificial ski slopes. | ||

| − | |||

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

| Line 11: | Line 10: | ||

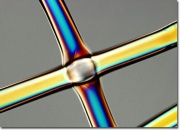

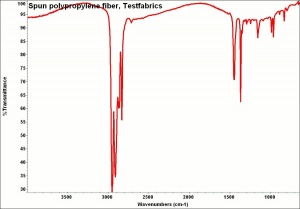

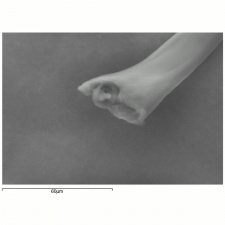

[[[SliderGallery rightalign|SpunpolypropyleneTestfabrics.jpg~FTIR|polyprop1000mm.jpg~SEM|polyprop200m.jpg~SEM]]] | [[[SliderGallery rightalign|SpunpolypropyleneTestfabrics.jpg~FTIR|polyprop1000mm.jpg~SEM|polyprop200m.jpg~SEM]]] | ||

| − | == | + | == Risks == |

| + | |||

| + | * May accumulate static electricity. | ||

| + | * Burns with a heavy, sooty, waxy smoke. | ||

| + | * Degraded by ultraviolet light and may contain UV absorbers or antioxidants. | ||

| + | == Physical and Chemical Properties == | ||

| − | Soluble in perchloroethylene, but may be dry-cleaned in cold trichloroethylene or white spirit. Resistant to strong acids and alkalis. Cross sections = circular or elliptical . Tenacity = 3.5-9.0 g/denier; Moisture regain = | + | Soluble in perchloroethylene, but may be dry-cleaned in cold trichloroethylene or white spirit. Resistant to strong acids and alkalis. Cross sections = circular or elliptical . Tenacity = 3.5-9.0 g/denier; Moisture regain = 0% |

{| class="wikitable" | {| class="wikitable" | ||

| Line 24: | Line 28: | ||

|- | |- | ||

! scope="row"| Melting Point | ! scope="row"| Melting Point | ||

| − | | 160- | + | | 160-170 C |

|- | |- | ||

! scope="row"| Density | ! scope="row"| Density | ||

| − | | 0.85-0.94 | + | | 0.85-0.94 g/ml |

|} | |} | ||

| − | |||

| − | |||

| − | |||

| − | |||

== Comparisons == | == Comparisons == | ||

| Line 40: | Line 40: | ||

[[media:download_file_82.pdf|Fiber Burn Tests]] | [[media:download_file_82.pdf|Fiber Burn Tests]] | ||

| − | == | + | == Resources and Citations == |

| + | * Textile Fashion Study: [http://textilefashionstudy.com/polypropylene-fiber-physical-and-chemical-properties-of-polypropylene/ Polypropylene] | ||

* Hoechst Celanese Corporation, ''Dictionary of Fiber & Textile Technology'' (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990 | * Hoechst Celanese Corporation, ''Dictionary of Fiber & Textile Technology'' (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990 | ||

Latest revision as of 09:59, 18 October 2022

Description

A manufactured fiber made from the polymers or copolymers of Polypropylene. In 1954, Giulio Natta (Milan Polytechnic, Italy) polymerized propylene and by 1957 polypropylene fibers were being commercially produced by Montecatini Societa Generale (Italy). Polypropylene fibers are lightweight, smooth and white with a slightly waxy feel. They are resistant to wear, crushing, acids, alkalis, moisture, fungi, and insects. Olefin fibers slowly degrade in sunlight and can be stained by oils. Polypropylene fibers are used to make rope, fishing nets, sewing threads, diaper covers, indoor-outdoor carpeting, artificial grass, upholstery fabrics, and stay-dry clothing. They are also used for geotextiles fabrics, pavement repair, roofing felts, and artificial ski slopes.

Synonyms and Related Terms

polypropylene fibre; polyolefin; olefin; Celestra; Herculon; Marvess; Patlon; Typar; Fibrite; Meraklon; Aberclare; Deltafil; Gymlene; Neolfil; Polycrest; Reevon; Spunstron; Tritor;fibras de polipropileno (Esp.)

Risks

- May accumulate static electricity.

- Burns with a heavy, sooty, waxy smoke.

- Degraded by ultraviolet light and may contain UV absorbers or antioxidants.

Physical and Chemical Properties

Soluble in perchloroethylene, but may be dry-cleaned in cold trichloroethylene or white spirit. Resistant to strong acids and alkalis. Cross sections = circular or elliptical . Tenacity = 3.5-9.0 g/denier; Moisture regain = 0%

| Composition | [C3H5]n |

|---|---|

| CAS | 9003-07-0 |

| Melting Point | 160-170 C |

| Density | 0.85-0.94 g/ml |

Comparisons

Properties of Synthetic Fibers

Resources and Citations

- Textile Fashion Study: Polypropylene

- Hoechst Celanese Corporation, Dictionary of Fiber & Textile Technology (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990

- Marjory L. Joseph, Introductory Textile Science, Holt, Rinehart and Winston, Fort Worth, TX, 1986

- Identification of Textile Materials, The Textile Institute, Manchester, England, 1985

- J.Gordon Cook, Handbook of Textile Fibres:II Man-made Fibres, Merrow Publishing Co. , Durham, England

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p.637