Difference between revisions of "Acrylonitrile butadiene styrene"

(username removed) |

|||

| (10 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

== Description == | == Description == | ||

| − | A family of [ | + | A family of [[thermoplastic|thermoplastic]] polymers prepared by either grafting [[styrene|styrene]] and [[acrylonitrile|acrylonitrile]] onto an elastomeric [[polybutadiene|polybutadiene]] backbone or by mechanically blending rubber copolymer matrices of styrene-acrylonitrile with butadiene-acrylonitrile. Varying the ratios of the three monomers produces a wide range of properties. Acrylonitrile provides resistance to chemicals, high temperatures, and creep deformation while butadiene adds toughness and styrene gives high modulus of elasticity and low cost. The standard grade of ABS resin is strong, resilient, and difficult to break. The polymer can be injection molded or extruded into numerous shapes. ABS resin is used for appliances, automobile parts and fittings, telephones, radios, televisions, pipes and conduits, luggage, boats, toys, and bottles. |

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

| Line 8: | Line 8: | ||

Examples: Abson; Cycolac | Examples: Abson; Cycolac | ||

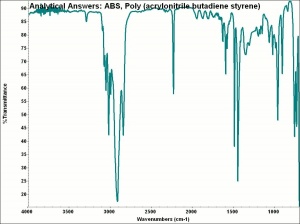

| + | [[[SliderGallery rightalign|aaiABS.jpg~FTIR]]] | ||

| + | |||

| + | == Applications == | ||

| + | * Usually reinforced with fibers or minerals or blended with other polymers | ||

| + | * Used in autos, appliances, household goods, and electronics | ||

| + | * Often used in 3d printing | ||

| + | == Personal Risks == | ||

| + | |||

| + | * Combustible, slow-burning, generates smoke. | ||

| + | * ABS: [[https://www.acplasticsinc.com/techsheets/ABS_MSDS.pdf| Safety Data Sheet]] | ||

| + | == Collection Risks == | ||

| + | |||

| + | '''Links to Oddy Test results posted on AIC Wiki Materials Database Pages for individual materials below'''<br> | ||

| − | [[ | + | ° [http://www.conservation-wiki.com/wiki/Oddy_Test_Results:_Exhibition_Fabrics#abs0001 Makerbot Industries ABS, Dark Sanguine Red] Tested in 2017 |

| + | |||

| + | ° [http://www.conservation-wiki.com/wiki/Oddy_Test_Results:_Exhibition_Fabrics#abs0002 Makerbot Industries ABS, white] Tested in 2017 | ||

| − | + | ° [http://www.conservation-wiki.com/wiki/Oddy_Test_Results:_Exhibition_Fabrics#abs0003 Makerbot Industries ABS, white] Tested in 2017 | |

| − | + | ° [http://www.conservation-wiki.com/wiki/Oddy_Test_Results:_Exhibition_Fabrics#abs0004 Makerbot Industries ABS, Dark Sanguine Red] Tested in 2017 | |

| − | == | + | == Physical and Chemical Properties == |

| − | + | * Resistant to water, salts and oils | |

| + | * May be degraded by oxidizing acids and many organic solvents (aromatics, ketones, and alcohols). | ||

| + | * High rigidity and dimensional stability | ||

| + | * Good weldability | ||

| + | * High impact and abrasion resistance | ||

| + | * Good insulating properties; | ||

| + | * Recyclable (type 9) | ||

== Comparisons == | == Comparisons == | ||

| Line 25: | Line 46: | ||

[[media:download_file_323.pdf|Physical Properties for Selected Thermoplastic Resins]] | [[media:download_file_323.pdf|Physical Properties for Selected Thermoplastic Resins]] | ||

| − | + | == Resources and Citations == | |

| − | + | * Omnexus: [https://omnexus.specialchem.com/selection-guide/acrylonitrile-butadiene-styrene-abs-plastic Guide to ABS plastics] | |

| − | == | ||

| − | |||

* G.S.Brady, ''Materials Handbook'', McGraw-Hill Book Co., New York, 1971 Comment: p. 12 | * G.S.Brady, ''Materials Handbook'', McGraw-Hill Book Co., New York, 1971 Comment: p. 12 | ||

| − | |||

* Pam Hatchfield, ''Pollutants in the Museum Environment'', Archetype Press, London, 2002 | * Pam Hatchfield, ''Pollutants in the Museum Environment'', Archetype Press, London, 2002 | ||

| − | |||

* Sharon Blank, An introduction to plastics and rubbers in collections, ''Studies in Conservation'', 35, 53-63, 1990 | * Sharon Blank, An introduction to plastics and rubbers in collections, ''Studies in Conservation'', 35, 53-63, 1990 | ||

| − | |||

* Theodore J. Reinhart, 'Glossary of Terms', ''Engineered Plastics'', ASM International, 1988 | * Theodore J. Reinhart, 'Glossary of Terms', ''Engineered Plastics'', ASM International, 1988 | ||

| − | [[Category:Materials database]] | + | [[Category:Materials database]][[Category:MWG]][[Category:Tubing/Rod]] |

Latest revision as of 11:02, 18 September 2023

Description

A family of Thermoplastic polymers prepared by either grafting Styrene and Acrylonitrile onto an elastomeric Polybutadiene backbone or by mechanically blending rubber copolymer matrices of styrene-acrylonitrile with butadiene-acrylonitrile. Varying the ratios of the three monomers produces a wide range of properties. Acrylonitrile provides resistance to chemicals, high temperatures, and creep deformation while butadiene adds toughness and styrene gives high modulus of elasticity and low cost. The standard grade of ABS resin is strong, resilient, and difficult to break. The polymer can be injection molded or extruded into numerous shapes. ABS resin is used for appliances, automobile parts and fittings, telephones, radios, televisions, pipes and conduits, luggage, boats, toys, and bottles.

Synonyms and Related Terms

ABS; acrylonitrile-butadiene-styrene resin; resina de acrilonitrilo-butadieno-estireno (Esp.); resina de acrilonitrilo-butadieno-estireno (Port.)

Examples: Abson; Cycolac

Applications

- Usually reinforced with fibers or minerals or blended with other polymers

- Used in autos, appliances, household goods, and electronics

- Often used in 3d printing

Personal Risks

- Combustible, slow-burning, generates smoke.

- ABS: [Safety Data Sheet]

Collection Risks

Links to Oddy Test results posted on AIC Wiki Materials Database Pages for individual materials below

° Makerbot Industries ABS, Dark Sanguine Red Tested in 2017

° Makerbot Industries ABS, white Tested in 2017

° Makerbot Industries ABS, white Tested in 2017

° Makerbot Industries ABS, Dark Sanguine Red Tested in 2017

Physical and Chemical Properties

- Resistant to water, salts and oils

- May be degraded by oxidizing acids and many organic solvents (aromatics, ketones, and alcohols).

- High rigidity and dimensional stability

- Good weldability

- High impact and abrasion resistance

- Good insulating properties;

- Recyclable (type 9)

Comparisons

General Characteristics of Polymers

Physical Properties for Selected Thermoplastic Resins

Resources and Citations

- Omnexus: Guide to ABS plastics

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 12

- Pam Hatchfield, Pollutants in the Museum Environment, Archetype Press, London, 2002

- Sharon Blank, An introduction to plastics and rubbers in collections, Studies in Conservation, 35, 53-63, 1990

- Theodore J. Reinhart, 'Glossary of Terms', Engineered Plastics, ASM International, 1988