Difference between revisions of "Rayon fiber"

m (Text replace - "\[http:\/\/cameo\.mfa\.org\/materials\/fullrecord\.asp\?name=([^\s]+)\s(.*)\]" to "$2") |

|||

| (6 intermediate revisions by the same user not shown) | |||

| Line 3: | Line 3: | ||

A manufactured fiber composed of [[regenerated%20cellulose|regenerated cellulose]] in which substituents have replaced no more than 15% of the hydrogens of the hydroxyl groups (Federal Trade Commission definition). Rayon was the first major commercial synthetic fiber. There are three primary fiber production methods for rayon. The first, developed in 1890, was the cuprammonium process (see [[cupro%20fiber|cupro]] fiber). The second, and most widely used process, called [[viscose%20rayon|viscose]], was developed in 1892. Viscose rayon can be further processed to form high tenacity and high wet modulus rayons (see [[modal%20fiber|modal]] and [[polynosic%20fiber|polynosic]] fibers). The third method for making rayon fibers is to saponify cellulose acetate fibers (see [[acetate%20rayon|acetate rayon]]). Rayons are used for woven and nonwoven fabrics, rubbers, felts, tire cords and [[cellophane|cellophane]]. | A manufactured fiber composed of [[regenerated%20cellulose|regenerated cellulose]] in which substituents have replaced no more than 15% of the hydrogens of the hydroxyl groups (Federal Trade Commission definition). Rayon was the first major commercial synthetic fiber. There are three primary fiber production methods for rayon. The first, developed in 1890, was the cuprammonium process (see [[cupro%20fiber|cupro]] fiber). The second, and most widely used process, called [[viscose%20rayon|viscose]], was developed in 1892. Viscose rayon can be further processed to form high tenacity and high wet modulus rayons (see [[modal%20fiber|modal]] and [[polynosic%20fiber|polynosic]] fibers). The third method for making rayon fibers is to saponify cellulose acetate fibers (see [[acetate%20rayon|acetate rayon]]). Rayons are used for woven and nonwoven fabrics, rubbers, felts, tire cords and [[cellophane|cellophane]]. | ||

| + | |||

| + | For identification of rayon fibers, see http://cameo.mfa.org/wiki/Category:FRIL:_Rayon | ||

[[File:1986.562b-SC10343.jpg|thumb|]] | [[File:1986.562b-SC10343.jpg|thumb|]] | ||

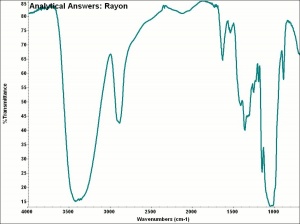

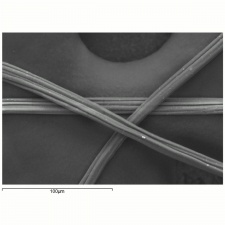

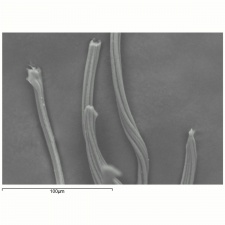

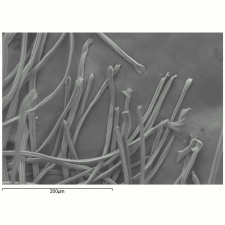

| + | [[[SliderGallery rightalign|aaiRAYON.jpg~FTIR|diacetate400m.jpg~SEM|tenasco500m.jpg~SEM|viscose250m.jpg~SEM]]] | ||

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

| − | rayon fibre (Br.); rayonne fibre (Fr.); artificial silk; art silk; fiber silk; viscose; cupro; modal; polynosic | + | rayon fibre (Br.); rayonne fibre (Fr.); artificial silk; art silk; fiber silk; viscose; [[cupro fiber]]; modal; polynosic; fibra de rayón(Esp.) |

| − | [ | + | Product names: Absorb; Beau-Grip; Coloray; Durvil; Enkaire; Enkrome; Fibro® [Acordis Cellulosic Fibers]; Zantrel; Fortisan; Avril®; Dynacor®; Enkal®; Nupron®; Rayflex®; Suprenka®; Tyrex®; Tyron®; |

| − | == | + | == Risks == |

| − | + | * Combustible, burning rapidly with a yellow flame and smell of burnt paper. It produces minimal ash. | |

| + | * Deteriorates slowly in sunlight. Resistant to most insects except silverfish. | ||

| − | + | == Physical and Chemical Properties == | |

| − | + | *Degrades in strong alkalis, acids and undiluted bleaches. | |

| − | + | *Resistant to dry cleaning solvents. | |

| − | + | *Filaments are smooth with striations; cross sections are circular with serrated edges. | |

| − | + | *Tenacity = 2.0-2.6 g/denier (dry); 1.0-1.5 (wet); | |

| − | + | *Moisture regain = 11-16.6%; | |

| − | + | *Elongation = 15-13% (dry); 20-40% (wet) | |

| − | + | *Melting Point = 150 (dec) | |

| − | + | *Density = 1.46-1.54 | |

| − | |||

| − | |||

| − | |||

| − | |||

== Additional Information == | == Additional Information == | ||

| Line 36: | Line 36: | ||

== Comparisons == | == Comparisons == | ||

| − | [[media: | + | [[media:download_file_78.pdf|Properties of Synthetic Fibers]] |

| − | |||

| − | |||

| − | |||

| + | [[media:download_file_79.pdf|Fiber Burn Tests]] | ||

== Additional Images == | == Additional Images == | ||

| Line 52: | Line 50: | ||

</gallery> | </gallery> | ||

| + | == Comparisons == | ||

| + | |||

| + | [[media:download_file_46.pdf|Properties of Synthetic Fibers]] | ||

| − | == | + | == Resources and Citations == |

* Hoechst Celanese Corporation, ''Dictionary of Fiber & Textile Technology'' (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990 | * Hoechst Celanese Corporation, ''Dictionary of Fiber & Textile Technology'' (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990 | ||

Latest revision as of 11:10, 14 July 2022

Description

A manufactured fiber composed of Regenerated cellulose in which substituents have replaced no more than 15% of the hydrogens of the hydroxyl groups (Federal Trade Commission definition). Rayon was the first major commercial synthetic fiber. There are three primary fiber production methods for rayon. The first, developed in 1890, was the cuprammonium process (see cupro fiber). The second, and most widely used process, called viscose, was developed in 1892. Viscose rayon can be further processed to form high tenacity and high wet modulus rayons (see modal and polynosic fibers). The third method for making rayon fibers is to saponify cellulose acetate fibers (see Acetate rayon). Rayons are used for woven and nonwoven fabrics, rubbers, felts, tire cords and Cellophane.

For identification of rayon fibers, see http://cameo.mfa.org/wiki/Category:FRIL:_Rayon

Synonyms and Related Terms

rayon fibre (Br.); rayonne fibre (Fr.); artificial silk; art silk; fiber silk; viscose; Cupro fiber; modal; polynosic; fibra de rayón(Esp.)

Product names: Absorb; Beau-Grip; Coloray; Durvil; Enkaire; Enkrome; Fibro® [Acordis Cellulosic Fibers]; Zantrel; Fortisan; Avril®; Dynacor®; Enkal®; Nupron®; Rayflex®; Suprenka®; Tyrex®; Tyron®;

Risks

- Combustible, burning rapidly with a yellow flame and smell of burnt paper. It produces minimal ash.

- Deteriorates slowly in sunlight. Resistant to most insects except silverfish.

Physical and Chemical Properties

- Degrades in strong alkalis, acids and undiluted bleaches.

- Resistant to dry cleaning solvents.

- Filaments are smooth with striations; cross sections are circular with serrated edges.

- Tenacity = 2.0-2.6 g/denier (dry); 1.0-1.5 (wet);

- Moisture regain = 11-16.6%;

- Elongation = 15-13% (dry); 20-40% (wet)

- Melting Point = 150 (dec)

- Density = 1.46-1.54

Additional Information

G.Cook, Handbook of Textile Fibres:II. Man-made Fibres, 5th edition, Merrow Publishing Co., Durham, England, 1984, p.9.

Comparisons

Properties of Synthetic Fibers

Additional Images

Comparisons

Properties of Synthetic Fibers

Resources and Citations

- Hoechst Celanese Corporation, Dictionary of Fiber & Textile Technology (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990

- S.R.Trotman, E.R. Trotman, Textile Analysis, J.B. Lippincott Company, Philadelphia, 1932

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985

- Matt Roberts, Don Etherington, Bookbinding and the Conservation of Books: a Dictionary of Descriptive Terminology, U.S. Government Printing Office, Washington DC, 1982

- Marjory L. Joseph, Introductory Textile Science, Holt, Rinehart and Winston, Fort Worth, TX, 1986

- J.Gordon Cook, Handbook of Textile Fibres:II Man-made Fibres, Merrow Publishing Co. , Durham, England

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 654

- Richard S. Lewis, Hawley's Condensed Chemical Dictionary, Van Nostrand Reinhold, New York, 10th ed., 1993

- Art and Architecture Thesaurus Online, http://www.getty.edu/research/tools/vocabulary/aat/, J. Paul Getty Trust, Los Angeles, 2000