Difference between revisions of "Dartek"

| (One intermediate revision by the same user not shown) | |||

| Line 60: | Line 60: | ||

| − | [[Category:Materials database]] [[Category:MWG]] [[Category:PACCIN]][[Category: Sheet/Film, Plastic]] | + | [[Category:Materials database]] [[Category:MWG]] [[Category:PACCIN]][[Category: Sheet/Film, Plastic]][[Category:Glazing]] |

Latest revision as of 08:36, 4 March 2023

Description

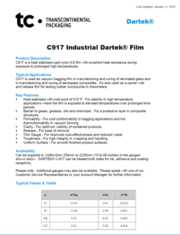

[Transcontinental] A registered trademark originally for DuPont (Canada) for a Thermoplastic, nylon film composed of Nylon 6,6. Dartek® is a clear, strong, tear-resistant film that has low oxygen and moisture permeability, abrasion resistance, excellent gas and oil barrier protection, and tensile strength. [1] Capable of absorbing up to 10% of its weight in moisture resulting in greater pliability over irregular surfaces. [2] The soft, transparent, stretchable film will conform to any shape using vacuum or gentle heating, such as with a hair dryer.

Of the Dartek® films available, C-917 is the most commonly used for art packing, storage, and conservation as it has no plasticizers or surface coating (PACCIN), contains a heat stabilizing additive (melt point of 510°F), and is low-shrink. [3]

Dartek® is used in industry for lamination and packaging. Manufactured by Transcontinental as of 2007.

As of 2020 all Dartek varietals listed below were discontinued [4]:

- B-601 : Barrier film, 25 micron thickness, used for thermoforming, laminating and film extrusion

- B-602 : Barrier film, 25 micron thickness, PVDC coated

- F-101 : Forming film, 25 micron thickness no additives; can be printed, laminated or extrusion coated

- N-201 : Non-forming film, 25 micron thickness

Synonyms and Related Terms

Dartek®; nylon-66; Dartex (sp); Dartek C-917

Applications

- Dust cover where light sensitivity is not an issue

- Replacement for Glassine when wrapping paintings susceptible to tackiness or abrasion

- A covering membrane on a vacuum tables used in painting conservation [5]

- Marketed by its manufacturer for wrapping, handling, transporting and storing paintings and fine art.

Personal Risks

Collection Risks

Physical and Chemical Properties

For a 1 mil film:

- Oxygen transmission = 54.3 ml/m2d

- Water vapor transmission = 295 g/m2d

- Density=1.13

Films do not contain additives or plasticizers. Can absorb up to 10% of its weight in moisture.

Working Properties

The tear resistant film has a 'saran-wrap' feel and clarity that is softer and more pliable than Mylar or Glassine. Moisture and heat should be avoided as is may cause the film to stick. Adheres with hot melt or double sides tape to other surfaces, or itself or other plastics using a heated spatula or tacking iron. Can be cut with scissors. Unlike the slightly milky LDPE, Dartek is water clear (PACCIN). In dry environments, the films can be brittle. Dartek C-917 can be treated on both sides for ink, adhesive and coating receptivity.

Forms and Sizes

Available in rolls from 10” to 88” wide and in gauges from .0075" (.19 mil) to 0.75” (1.9 mil).[6] 100, 150, 200, 500 ft. length rolls (depending on supplier).

Resources and Citations

- Kaela Nurmi, contributed information, MWG group, 2020.

- Dartek product page, Transcontinental Website

- Preparation, Art Handling, Collections Care Information Network (PACCIN)

- Talas: C-917 NA High Performance Industrial Film Data Sheet

- Book and Paper Group, Paper Conservation Catalog, AIC, 1984, 1989

- Marie Svoboda, Conservation Survey Index, unpublished, 1997

- Teri Hensick, contributed information, 1998

- Conservation Support Systems, Catalog, 1997