Difference between revisions of "Aluminum foam"

Jump to navigation

Jump to search

| Line 2: | Line 2: | ||

[[File:Al foam formed.jpg|thumb|Formed aluminum foam from Wikipedia [https://commons.wikimedia.org/wiki/File:Alv%C3%A9oles_4.jpg link]]] | [[File:Al foam formed.jpg|thumb|Formed aluminum foam from Wikipedia [https://commons.wikimedia.org/wiki/File:Alv%C3%A9oles_4.jpg link]]] | ||

==Description== | ==Description== | ||

| − | Lightweight metallic sheets usually formed air or gas injected into the molten aluminum. Aluminum foams are very strong, nonflammable and eco-friendly. | + | Lightweight metallic sheets usually formed air or gas injected into the molten aluminum. Aluminum foams are very strong, nonflammable and eco-friendly. They have excellent impact absorption and are used for collision protection in transport systems; however, unlike polymer foams, when an impact happens, they remain deformed and can only be used once. |

| + | Foamed metals are available both in closed cell and open cell forms. | ||

* Open-celled metal foams are usually replicas produced using open-celled polyurethane foams as a skeleton | * Open-celled metal foams are usually replicas produced using open-celled polyurethane foams as a skeleton | ||

| − | * Closed-cell metal foams have been developed since the 1950s, but although prototypes were available, commercial production was started only in the 1990s. | + | * Closed-cell metal foams have been developed since the 1950s, but although prototypes were available, commercial production was started only in the 1990s. They made by injecting a gas into molten metal forming pores, or cells, about 1 to 8 mm in size. |

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

| Line 13: | Line 14: | ||

==Applications== | ==Applications== | ||

| − | * Sound insulation | + | * Sound and impact insulation |

* Architectural facades | * Architectural facades | ||

* Lightweight case construction | * Lightweight case construction | ||

Latest revision as of 12:19, 7 February 2024

Formed aluminum foam from Wikipedia link

Description

Lightweight metallic sheets usually formed air or gas injected into the molten aluminum. Aluminum foams are very strong, nonflammable and eco-friendly. They have excellent impact absorption and are used for collision protection in transport systems; however, unlike polymer foams, when an impact happens, they remain deformed and can only be used once.

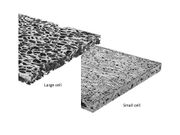

Foamed metals are available both in closed cell and open cell forms.

- Open-celled metal foams are usually replicas produced using open-celled polyurethane foams as a skeleton

- Closed-cell metal foams have been developed since the 1950s, but although prototypes were available, commercial production was started only in the 1990s. They made by injecting a gas into molten metal forming pores, or cells, about 1 to 8 mm in size.

Synonyms and Related Terms

foamed aluminum; metal sponge

Commercial products: Duocel

Applications

- Sound and impact insulation

- Architectural facades

- Lightweight case construction

- Heat exchangers

Physical and Chemical Properties

- Lightweight with high strength to weight ratio

- Density (relative to solid As) = 4-12% is most common

- Compression strength = 367 psi (at 8% relative density)

- Tensile strength = 180 psi (at 8% relative density)

- Melting point = 1220f (660C)

Working Properties

- Carbide- or diamond-tipped blades are required for machining

- Joined by brazing, adhesive bonding, mechanical fasteners, or soldering

Forms and Sizes

- Thicknesses from 1/2" to 2"

- Sheets available 6'x6' or 12'x12' (McMaster-Carr)

Resources and Citations

- Wikipedia: Metal foam Accessed Feb. 2024

- American Elements: Foams

- McMaster-Carr: Aluminum foam