Difference between revisions of "Kapok"

| Line 1: | Line 1: | ||

| + | [[File:Silk Cotton Tree MFA.jpg|thumb|Silk Cotton tree<br>MFA# 2013.5319]] | ||

[[File:KapoktreeKES.jpg|thumb|Kapok tree]] | [[File:KapoktreeKES.jpg|thumb|Kapok tree]] | ||

== Description == | == Description == | ||

| − | Short, lightweight [[Cellulose|cellulosic]] fibers obtained from the seeds of the silk cotton tree, ''Ceiba pentandra'', primarily grown in | + | Short, lightweight [[Cellulose|cellulosic]] fibers obtained from the seeds of the silk cotton tree, ''Ceiba pentandra'', primarily native to the tropical Americas and grown commercially in south-east Asia. Kapok is composed of 43% [[alpha cellulose]], 24% pentose, 15% [[lignin]], and 6.6% uronic anhydride. The soft fibers have a smooth surface and are transparent. Kapok is buoyant and will support up to 30 times its own weight. The fluffy fibers are too brittle to spin and are used for filling mattresses, upholstery, and life jackets. |

See also [[bombax]] and [[Indian kapok]]. | See also [[bombax]] and [[Indian kapok]]. | ||

| − | [[File:Kapok_tree_det.jpg|thumb|Silk cotton tree | + | [[File:Kapok_tree_det.jpg|thumb|Silk cotton tree (''Ceiba pentandra'')]] |

| − | |||

| − | (''Ceiba pentandra'')]] | ||

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

| Line 15: | Line 14: | ||

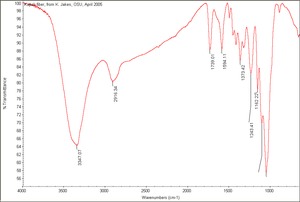

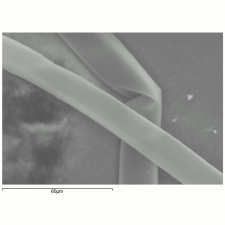

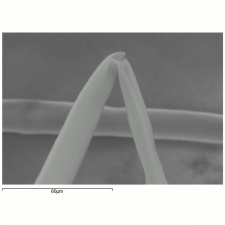

[[[SliderGallery rightalign|Kapok fiber, from K Jakes, OSU, April 2005.TIF~FTIR|kapok1000am.jpg~SEM|kapok1000bm.jpg~SEM]]] | [[[SliderGallery rightalign|Kapok fiber, from K Jakes, OSU, April 2005.TIF~FTIR|kapok1000am.jpg~SEM|kapok1000bm.jpg~SEM]]] | ||

| − | == | + | == Physical and Chemical Properties == |

Fiber length = 20 - 32 mm (0.75-1.25 inches); Diameter = 20 micrometers; Cross section is oval or circular. | Fiber length = 20 - 32 mm (0.75-1.25 inches); Diameter = 20 micrometers; Cross section is oval or circular. | ||

| Line 21: | Line 20: | ||

Paper fiber type: Non-woody/bast. Using transmitted light microscopy, fibers appear short and narrow with thick walls. Dislocations are present but faint. The ends of fibers can be spoon-shaped with widened lumen. Appearance with [[Graff "C" stain]]: Orange-red, but greys with bleaching. Average dimensions of fibers: length, 2mm, width 20μm. Common pulping method: [[soda process|soda]]. | Paper fiber type: Non-woody/bast. Using transmitted light microscopy, fibers appear short and narrow with thick walls. Dislocations are present but faint. The ends of fibers can be spoon-shaped with widened lumen. Appearance with [[Graff "C" stain]]: Orange-red, but greys with bleaching. Average dimensions of fibers: length, 2mm, width 20μm. Common pulping method: [[soda process|soda]]. | ||

| − | == | + | == Risks == |

Combustible. | Combustible. | ||

| Line 28: | Line 27: | ||

[[media:download_file_158.pdf|Properties of Natural Fibers]] | [[media:download_file_158.pdf|Properties of Natural Fibers]] | ||

| − | |||

| − | |||

== Additional Images == | == Additional Images == | ||

| Line 40: | Line 37: | ||

</gallery> | </gallery> | ||

| − | == | + | == Resources and Citations == |

* Hoechst Celanese Corporation, ''Dictionary of Fiber & Textile Technology'' (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990 | * Hoechst Celanese Corporation, ''Dictionary of Fiber & Textile Technology'' (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990 | ||

| Line 58: | Line 55: | ||

* Edward Reich, Carlton J. Siegler, ''Consumer Goods: How to Know and Use Them'', American Book Company, New York City, 1937 | * Edward Reich, Carlton J. Siegler, ''Consumer Goods: How to Know and Use Them'', American Book Company, New York City, 1937 | ||

| − | * Wikipedia | + | * Wikipedia: http://en.wikipedia.org/wiki/Kapok (Accessed Sept. 7, 2005) |

* G.S.Brady, ''Materials Handbook'', McGraw-Hill Book Co., New York, 1971 Comment: p. 430 | * G.S.Brady, ''Materials Handbook'', McGraw-Hill Book Co., New York, 1971 Comment: p. 430 | ||

Revision as of 14:08, 14 October 2020

Description

Short, lightweight cellulosic fibers obtained from the seeds of the silk cotton tree, Ceiba pentandra, primarily native to the tropical Americas and grown commercially in south-east Asia. Kapok is composed of 43% Alpha cellulose, 24% pentose, 15% Lignin, and 6.6% uronic anhydride. The soft fibers have a smooth surface and are transparent. Kapok is buoyant and will support up to 30 times its own weight. The fluffy fibers are too brittle to spin and are used for filling mattresses, upholstery, and life jackets.

See also Bombax and Indian kapok.

Synonyms and Related Terms

silk cotton tree (Ceiba pentandra); ceiba; samauma; Illiani silk; Java cotton; vegetable down; Java kapok; simal; balsam fiber; pochote; red silk cotton; Kapokbaum (Deut.); kapok (Fr.,Esp., Ned.)

Physical and Chemical Properties

Fiber length = 20 - 32 mm (0.75-1.25 inches); Diameter = 20 micrometers; Cross section is oval or circular.

Paper fiber type: Non-woody/bast. Using transmitted light microscopy, fibers appear short and narrow with thick walls. Dislocations are present but faint. The ends of fibers can be spoon-shaped with widened lumen. Appearance with Graff "C" stain: Orange-red, but greys with bleaching. Average dimensions of fibers: length, 2mm, width 20μm. Common pulping method: soda.

Risks

Combustible.

Comparisons

Additional Images

Resources and Citations

- Hoechst Celanese Corporation, Dictionary of Fiber & Textile Technology (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990

- S.R.Trotman, E.R. Trotman, Textile Analysis, J.B. Lippincott Company, Philadelphia, 1932

- Marja-Sisko Ilvessalo-Pfäffli. Fiber Atlas: Identification of Papermaking Fibers (Springer Series in Wood Science). Springer, 1995.

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985

- F. H. Titmuss, Commercial Timbers of the World, The Technical Press Ltd., London, 1965

- Marjory L. Joseph, Introductory Textile Science, Holt, Rinehart and Winston, Fort Worth, TX, 1986

- Walter Rantanen. "Fiber ID Course." Integrated Paper Services. June 2013. Lecture.

- Edward Reich, Carlton J. Siegler, Consumer Goods: How to Know and Use Them, American Book Company, New York City, 1937

- Wikipedia: http://en.wikipedia.org/wiki/Kapok (Accessed Sept. 7, 2005)

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 430

- Richard S. Lewis, Hawley's Condensed Chemical Dictionary, Van Nostrand Reinhold, New York, 10th ed., 1993

- Van Nostrand's Scientific Encyclopedia, Douglas M. Considine (ed.), Van Nostrand Reinhold, New York, 1976

- Random House, Webster's Encyclopedic Unabridged Dictionary of the English Language, Grammercy Book, New York, 1997

- The American Heritage Dictionary or Encarta, via Microsoft Bookshelf 98, Microsoft Corp., 1998

- Art and Architecture Thesaurus Online, http://www.getty.edu/research/tools/vocabulary/aat/, J. Paul Getty Trust, Los Angeles, 2000