Difference between revisions of "Polypropylene"

| Line 51: | Line 51: | ||

== Collection Risks == | == Collection Risks == | ||

| − | * Polypropylene is not susceptible to hydrolysis. “Highly hydrophobic polymers such as polyethylene and polypropylene are unlikely to have hydrolysable chemical groups, so are not subject to hydrolytic breakdown” | + | * Polypropylene is not susceptible to hydrolysis. “Highly hydrophobic polymers such as polyethylene and polypropylene are unlikely to have hydrolysable chemical groups, so are not subject to hydrolytic breakdown” |

* Exposure to ultraviolet radiation causes discoloration and embrittlement. Discoloration can cause loss of transparency for storage enclosures and embrittlement can result in decreased strength and loss of function of storage material. <ref>Scott R. Williams. Plastic Storage Products. In ‘Preventive Conservation: Collection Storage’ Lisa Elkin and Christopher A. Norris (eds.), Society for the Preservation of Natural History Collections, New York. 2019. 774</ref> | * Exposure to ultraviolet radiation causes discoloration and embrittlement. Discoloration can cause loss of transparency for storage enclosures and embrittlement can result in decreased strength and loss of function of storage material. <ref>Scott R. Williams. Plastic Storage Products. In ‘Preventive Conservation: Collection Storage’ Lisa Elkin and Christopher A. Norris (eds.), Society for the Preservation of Natural History Collections, New York. 2019. 774</ref> | ||

Revision as of 16:41, 27 July 2020

Description

A tough, translucent, white, thermoplastic Polyolefin made from propylene. In 1954, Giulio Natta (Milan Polytechnic, Italy) polymerized propylene, and by 1957, polypropylene fibers were being commercially produced by Montecatini Societa Generale (Italy). Polypropylene is similar to Polyethylene, but is slightly less dense with higher gloss, rigidity, and softening point. It has fair abrasion resistance and good resistance to heat and electricity. Polypropylene is the second most widely produced commodity plastic. Outside of museums, polypropylene is used for medical supplies, electrical appliances, toys, bottles, fishnets, pipe, clothing, road signs, molded parts, carpet, artificial grass, laminates, food packages, furniture, and photographic enclosures. Polypropylene is also made in a low molecular weight form that is used as greases, sealants, and wax.

Examples include:

| Forms | Products | |

|---|---|---|

| Film | frisket; Torayfan OPP | |

| Foam | Microfoam Pregis LLC; Propafoam Zotefoams Ltd.; Propazote | |

| Corrugated board | Matra Plast; Hi-Core Coroplast LLC; Coroplast (copolymer of polypropylene and polyethylene) | |

| Fabric non-woven | ||

| Pellets | Poly-Pellets | |

| Fluff | Poly-fil; |

Synonyms and Related Terms

PP; polyolefin; polipropileno (Esp.); polypropylène (Fr.); polipropilene (It.); Polypropylen (Deut.); polypropeen (Ned.); polipropileno (Port.); polypropen (Sven.)

Examples: Coroplast; Propylex; Herculon; Microfoam

Applications

- Corrugated board

- Fibers, non-woven fabric, protective sheets

- Vapor barrier films, protective sheets

- Waxes and lubricants

Personal Risks

Scientific Polymer Products: MSDS

Collection Risks

- Polypropylene is not susceptible to hydrolysis. “Highly hydrophobic polymers such as polyethylene and polypropylene are unlikely to have hydrolysable chemical groups, so are not subject to hydrolytic breakdown”

- Exposure to ultraviolet radiation causes discoloration and embrittlement. Discoloration can cause loss of transparency for storage enclosures and embrittlement can result in decreased strength and loss of function of storage material. [1]

Environmental Risks

- Some polypropylene products are made to be biodegradable and are not suitable for use as they are not stable.

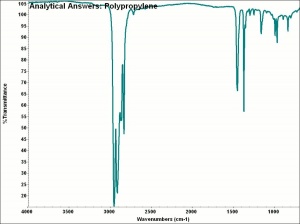

Physical and Chemical Properties

- Soluble in some hydrocarbons, isoamyl alcohol.

- Insoluble in acetone, diethyl ether, lower alcohols, ethyl acetate, acids, alkalis.

- Burns with yellow flame and blue center; smells of paraffin.

- General composition = [C3H5]n

- CAS = 9003-07-0

- Melting Point = 160-165

- Density =| 0.85-0.94

Comparisons

Physical Properties for Selected Thermoplastic Resins

General Characteristics of Polymers

Resources and Citations

- ↑ Scott R. Williams. Plastic Storage Products. In ‘Preventive Conservation: Collection Storage’ Lisa Elkin and Christopher A. Norris (eds.), Society for the Preservation of Natural History Collections, New York. 2019. 774

- Manfredi, Barberis, & Marengo. (2017). Prediction and classification of the degradation state of plastic materials used in modern and contemporary art. Applied Physics A, 123(1), 1-11.

- Contribution: Gina Watkinson, AIC Plastics Panel, 2020.

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 836

- Theodore J. Reinhart, 'Glossary of Terms', Engineered Plastics, ASM International, 1988

- Richard S. Lewis, Hawley's Condensed Chemical Dictionary, Van Nostrand Reinhold, New York, 10th ed., 1993

- Product Information Comment: Sigma Chemical MSDS has CAS 25085-53-4; Merck has CAS 9003-07-0 as does MSDS for Environmental Science; Scientific Polymer products has 9003-0704 for isotactic polypropylene

- History of Plastics: www.nswpmith.com.au/historyofplastics.html;

- Wikipedia: http://en.wikipedia.org/wiki/Polypropylene (Accessed Nov. 9, 2005)

- Art and Architecture Thesaurus Online, http://www.getty.edu/research/tools/vocabulary/aat/, J. Paul Getty Trust, Los Angeles, 2000