Polyester fiber

Description

A manufactured fiber in which the fiber-forming substance is any long chain synthetic polymer composed of at least 85% by weight of an ester of dihydric alcohol and terephthalic acid (Federal Trade Commission definition). The first viable polyester fiber (Terylene) was developed by English chemists, J. R. Whinfield, and J.T. Dickson, in 1941. It was first sold in the U.S. as Dacron in 1951 and is now the most widely used fiber, even surpassing cotton. Polyester is strong and resistant to shrinking, stretching, creasing, insects and most chemicals. The specific properties, however, vary significantly depending on the type of polyester fiber. Many are modified to increase flame, crush or oil resistance. The fiber cross section is often made into different shapes to change the feel and appearance of the fibers. Polyester is primarily used in clothing and home furnishings. It is often blended with Wool, Cotton, rayon, or Flax.

For polyester fiber identification, see http://cameo.mfa.org/wiki/Category:FRIL:_Polyester

Synonyms and Related Terms

polyester fibre; Dacron (originally called Fiber V) [DuPont]; Terylene [ICI]; Avlin; Beaunit; Tergal [Rhone-Poulenc]; Teteron; Trevira; Crimplene; Diolene; Fortrel [Wellman]; Grilene; Thermoloft; Microloft; Terital; Pellon; Reemay; Kodel [Eastman Chemical]; polyethylene terephthalate; PET; Encron; Spectran; Zephran; Polyester (Deut.); polister (Esp.); polyester (Fr., Sven.); poliestry(Pol.);

Risks

- Degrades in direct sunlight.

- Resistant to insects and microorganisms.

- Absorbs and holds oils.

- Builds up static charge.

- Polyester is difficult to ignite.

- Burns with a shiny, yellow-orange, sooty flame and sweet smell.

- Self-extinguishing when flame source is removed.

- Ash is hard.

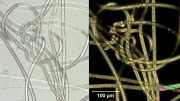

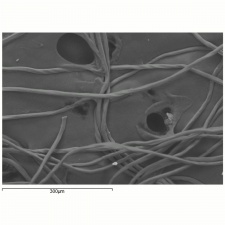

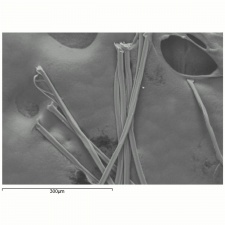

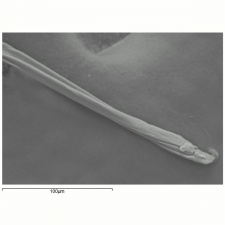

Physical and Chemical Properties

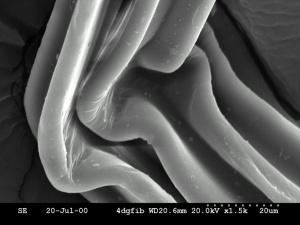

Resistant to weak acids, weak alkalis, bleach and most organic solvents. Degrades in strong alkalis, strong acids, cresol. Fibers are smooth. Cross section = circular, trilobal or polygon. Moisture regain 0.1-0.4%; Tenacity = 2.2-9.5 g/denier; Elongation = 10-50%

| Melting Point | 238-290 |

|---|---|

| Density | 1.23-1.38 |

| Refractive Index | 1.54, 1.72 |

Comparisons

Properties of Synthetic Fibers

Additional Images

Resources and Citations

- M. Joseph, Introductory Textile Science, Holt Reinhold & Winston, Fort Worth, 1986, p. 135.

- G.Cook, Handbook of Textile Fibres:II. Man-made Fibres, 5th edition, Merrow Publishing Co., Durham, England, 1984. p.328

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 626

- Marjorie Shelley, The Care and Handling of Art Objects, The Metropolitan Museum, New York, 1987

- Richard S. Lewis, Hawley's Condensed Chemical Dictionary, Van Nostrand Reinhold, New York, 10th ed., 1993

- Hoechst Celanese Corporation, Dictionary of Fiber & Textile Technology (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985

- Matt Roberts, Don Etherington, Bookbinding and the Conservation of Books: a Dictionary of Descriptive Terminology, U.S. Government Printing Office, Washington DC, 1982

- Identification of Textile Materials, The Textile Institute, Manchester, England, 1985

- The American Heritage Dictionary or Encarta, via Microsoft Bookshelf 98, Microsoft Corp., 1998

- Website: www.fabrics.net

- Wikipedia: http://en.wikipedia.org/wiki/Polyester (Accessed Feb. 10, 2006)