Aluminum foam

Jump to navigation

Jump to search

Formed aluminum foam from Wikipedia link

Description

Lightweight metallic sheets usually formed air or gas injected into the molten aluminum. Aluminum foams are very strong, nonflammable and eco-friendly. They have excellent impact absorption and are used for collision protection in transport systems; however, unlike polymer foams, when an impact happens, they remain deformed and can only be used once.

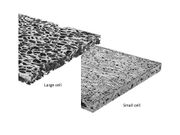

Foamed metals are available both in closed cell and open cell forms.

- Open-celled metal foams are usually replicas produced using open-celled polyurethane foams as a skeleton

- Closed-cell metal foams have been developed since the 1950s, but although prototypes were available, commercial production was started only in the 1990s. They made by injecting a gas into molten metal forming pores, or cells, about 1 to 8 mm in size.

Synonyms and Related Terms

foamed aluminum; metal sponge

Commercial products: Duocel

Applications

- Sound and impact insulation

- Architectural facades

- Lightweight case construction

- Heat exchangers

Physical and Chemical Properties

- Lightweight with high strength to weight ratio

- Density (relative to solid As) = 4-12% is most common

- Compression strength = 367 psi (at 8% relative density)

- Tensile strength = 180 psi (at 8% relative density)

- Melting point = 1220f (660C)

Working Properties

- Carbide- or diamond-tipped blades are required for machining

- Joined by brazing, adhesive bonding, mechanical fasteners, or soldering

Forms and Sizes

- Thicknesses from 1/2" to 2"

- Sheets available 6'x6' or 12'x12' (McMaster-Carr)

Resources and Citations

- Wikipedia: Metal foam Accessed Feb. 2024

- American Elements: Foams

- McMaster-Carr: Aluminum foam