Difference between revisions of "Nylon 6,6"

| Line 2: | Line 2: | ||

== Description == | == Description == | ||

| − | A polymer formed | + | A [[thermoplastic]] polymer formed by reacting a diamine with a diacid, often [[hexamethylenediamine]] with [[adipic acid]]. Nylon 6,6 was first developed in 1935 by W.H. Carothers at DuPont and patented in 1938 for use as a textile fiber. It was originally given the name Fiber #66. The fibers are known to be strong, tough, and elastic. Importantly, as opposed to traditional fibers such as cotton, wool, and rayon, nylon fibers are glossy. They are extruded through a spinneret with a circular or trilobal cross section shape. Nylon 6,6 fibers can be used individually, i.e., as monofilaments, for brushes, surgical sutures, tennis strings, and fishing lines. Nylon 6,6 fibers are used for clothing, carpets, tire cords, conveyor belts, and brushes. Nylon 6,6 exhibits excellent dyeability and are twice as durable as [[cotton|cotton]]. Nylon is sometimes coated with plastic, such as [[vinyl%20resin|vinyl]], to produce thin, lightweight waterproof fabrics. |

| + | The properties of nylon 6,6 are very similar to nylon 6, however the chemistry to synthesize these two polymers is different. | ||

See [[nylon%20fiber|nylon fiber]]. | See [[nylon%20fiber|nylon fiber]]. | ||

| − | |||

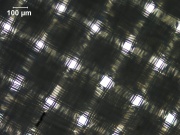

[[File:nylon 6_6_100X.jpg|thumb|Nylon 6,6]] | [[File:nylon 6_6_100X.jpg|thumb|Nylon 6,6]] | ||

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

| − | adipic nylon; Fiber #66; | + | polyamide 6,6; poly(hexamethylneadipamide); adipic nylon; Fiber #66; |

| + | Examples: Antron® [DuPont]; Cantrece® [DuPont]; Durasoft [Solutia]; Stainmaster [DuPont]; Wear-Dated [Solutia]; Brulon 240 [ICI]; Brulon 244 [ICI]; Perlon T [made in Germany] | ||

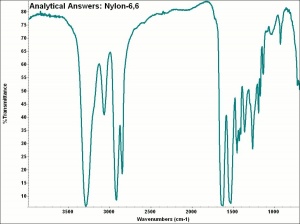

[[[SliderGallery rightalign|aaiNYLON-66.jpg~FTIR]]] | [[[SliderGallery rightalign|aaiNYLON-66.jpg~FTIR]]] | ||

| + | == Applications == | ||

| + | |||

| + | == Personal Risks == | ||

| + | |||

| + | Nylon 6,6 is generally a safe material to handle. | ||

| + | == Collection Risks == | ||

| + | |||

| + | Can be sensitive to temperature fluctuations. Typically pretty stable although it was proposed to be a material ill-suited for use in conservation. | ||

| + | == Environmental Risks == | ||

| − | + | Nylon 6,6 is not biodegradable. Manufacturing process releases nitrous oxide, a greenhouse gas. | |

| − | + | == Physical and Chemical Properties == | |

| − | + | Resistant to alkalis and most organic solvents. Degraded by acids and phenol. Burns with yellow-orange flame and blue smoke; smells of burnt horn. Fibers are smooth with no striations. | |

| − | + | * Cross section is circular or trilobal. | |

| − | + | * Tenacity = 4.6-9.0 g/denier (dry); 4.0-7.7 (wet); | |

| − | + | * Elongation = 19-40% (dry); 32-46% (wet); | |

| − | + | * Moisture regain = 3.8-4.5% (dry) | |

| − | + | * Melting Point = 250 | |

| − | + | * Density = 1.14 | |

| − | + | * Refractive Index = 1.521; 1.547 | |

| − | |||

| − | |||

| − | |||

== Comparisons == | == Comparisons == | ||

| Line 41: | Line 48: | ||

</gallery> | </gallery> | ||

| − | == | + | == Resources and Citations == |

* G.S.Brady, ''Materials Handbook'', McGraw-Hill Book Co., New York, 1971 Comment: p. 553 | * G.S.Brady, ''Materials Handbook'', McGraw-Hill Book Co., New York, 1971 Comment: p. 553 | ||

| Line 55: | Line 62: | ||

* Meredith Montague, contributed information, 1998 | * Meredith Montague, contributed information, 1998 | ||

| − | * | + | * History of Plastics: www.nswpmith.com.au/historyofplastics.html |

[[Category:Materials database]] | [[Category:Materials database]] | ||

Revision as of 11:42, 5 July 2020

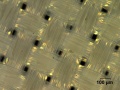

Description

A Thermoplastic polymer formed by reacting a diamine with a diacid, often Hexamethylenediamine with Adipic acid. Nylon 6,6 was first developed in 1935 by W.H. Carothers at DuPont and patented in 1938 for use as a textile fiber. It was originally given the name Fiber #66. The fibers are known to be strong, tough, and elastic. Importantly, as opposed to traditional fibers such as cotton, wool, and rayon, nylon fibers are glossy. They are extruded through a spinneret with a circular or trilobal cross section shape. Nylon 6,6 fibers can be used individually, i.e., as monofilaments, for brushes, surgical sutures, tennis strings, and fishing lines. Nylon 6,6 fibers are used for clothing, carpets, tire cords, conveyor belts, and brushes. Nylon 6,6 exhibits excellent dyeability and are twice as durable as Cotton. Nylon is sometimes coated with plastic, such as vinyl, to produce thin, lightweight waterproof fabrics.

The properties of nylon 6,6 are very similar to nylon 6, however the chemistry to synthesize these two polymers is different. See Nylon fiber.

Synonyms and Related Terms

polyamide 6,6; poly(hexamethylneadipamide); adipic nylon; Fiber #66;

Examples: Antron® [DuPont]; Cantrece® [DuPont]; Durasoft [Solutia]; Stainmaster [DuPont]; Wear-Dated [Solutia]; Brulon 240 [ICI]; Brulon 244 [ICI]; Perlon T [made in Germany]

Applications

Personal Risks

Nylon 6,6 is generally a safe material to handle.

Collection Risks

Can be sensitive to temperature fluctuations. Typically pretty stable although it was proposed to be a material ill-suited for use in conservation.

Environmental Risks

Nylon 6,6 is not biodegradable. Manufacturing process releases nitrous oxide, a greenhouse gas.

Physical and Chemical Properties

Resistant to alkalis and most organic solvents. Degraded by acids and phenol. Burns with yellow-orange flame and blue smoke; smells of burnt horn. Fibers are smooth with no striations.

- Cross section is circular or trilobal.

- Tenacity = 4.6-9.0 g/denier (dry); 4.0-7.7 (wet);

- Elongation = 19-40% (dry); 32-46% (wet);

- Moisture regain = 3.8-4.5% (dry)

- Melting Point = 250

- Density = 1.14

- Refractive Index = 1.521; 1.547

Comparisons

Properties of Synthetic Fibers

Additional Images

Resources and Citations

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 553

- Richard S. Lewis, Hawley's Condensed Chemical Dictionary, Van Nostrand Reinhold, New York, 10th ed., 1993

- Marjory L. Joseph, Introductory Textile Science, Holt, Rinehart and Winston, Fort Worth, TX, 1986, p. 135.

- J.Gordon Cook, Handbook of Textile Fibres:II Man-made Fibres, Merrow Publishing Co., Durham, England

- F. Kidd, Brushmaking Materials, Bristish Brush Manufacturers, London, 1957

- Meredith Montague, contributed information, 1998

- History of Plastics: www.nswpmith.com.au/historyofplastics.html