Difference between revisions of "Casein fiber"

(username removed) |

|||

| (2 intermediate revisions by 2 users not shown) | |||

| Line 2: | Line 2: | ||

== Description == | == Description == | ||

| − | Regenerated [ | + | Regenerated [[protein fiber|protein fibers]] made from polymerized [[casein]]. In the early 1930s, an Italian chemist, Antonio Ferretti developed a successful method to make casein into fibers (see [[Lanital]]). Casein is processed with [[formaldehyde]] or [[benzaldehyde]] and metal salts then pressed through spinnerets to form long, silklike fibers. Casein fibers are softer and smoother than [[wool]] and contain less [[sulfur]]. They are not susceptible to moths but can be degraded by some bacteria. Casein fibers are usually cream colored. They accept dyes well but have poor washfastness. Most often casein fibers are blended with wool in fabrics, carpets and hat felts. Lanital, along with other regenerated protein fibers, have been replaced by other synthetic fibers, because casein fibers were weak when wet and susceptible to microbiological growths. |

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

| Line 10: | Line 10: | ||

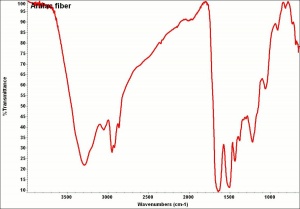

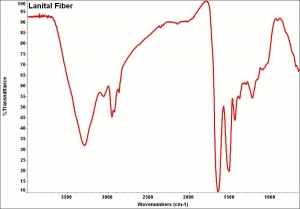

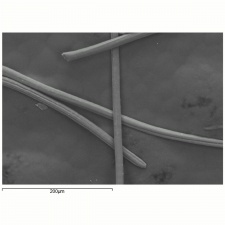

[[[SliderGallery rightalign|Aralacfiberkj1.jpg~FTIR|LanitaFiberkj1.jpg~FTIR|Aralacfiberkj1.jpg~FTIR|LanitaFiberkj1.jpg~FTIR|aralac300m.jpg~SEM|lanital250m.jpg~SEM]]] | [[[SliderGallery rightalign|Aralacfiberkj1.jpg~FTIR|LanitaFiberkj1.jpg~FTIR|Aralacfiberkj1.jpg~FTIR|LanitaFiberkj1.jpg~FTIR|aralac300m.jpg~SEM|lanital250m.jpg~SEM]]] | ||

| − | == | + | == Risks == |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Burns slowly and brightly in air, but extinguishes with removal of flame source. | Burns slowly and brightly in air, but extinguishes with removal of flame source. | ||

| + | == Physical and Chemical Properties == | ||

| − | + | Insoluble in dilute acids, hydrogen peroxide and most organic solvents. Affected by alkalis. Burns with odor of burning hair. | |

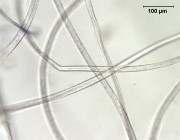

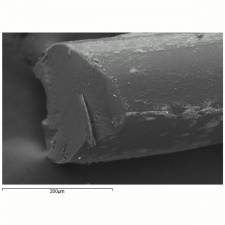

| − | + | Filaments are smooth. Cross sections = circular, bean-shaped. Diameter=20-30 micrometers. Tenacity = 0.9-1.1 g/denier (dry); 0.3-0.6 (wet); Elongation =60-70%; Moisture regain = 14%; Melting Point = 150 C (dec); Density = 1.30 gm/cc | |

| − | == | + | == Resources and Citations == |

* ''Identification of Textile Materials'', The Textile Institute, Manchester, England, 1985 | * ''Identification of Textile Materials'', The Textile Institute, Manchester, England, 1985 | ||

Latest revision as of 11:54, 5 December 2020

Description

Regenerated protein fibers made from polymerized Casein. In the early 1930s, an Italian chemist, Antonio Ferretti developed a successful method to make casein into fibers (see Lanital). Casein is processed with Formaldehyde or Benzaldehyde and metal salts then pressed through spinnerets to form long, silklike fibers. Casein fibers are softer and smoother than Wool and contain less Sulfur. They are not susceptible to moths but can be degraded by some bacteria. Casein fibers are usually cream colored. They accept dyes well but have poor washfastness. Most often casein fibers are blended with wool in fabrics, carpets and hat felts. Lanital, along with other regenerated protein fibers, have been replaced by other synthetic fibers, because casein fibers were weak when wet and susceptible to microbiological growths.

Synonyms and Related Terms

casein fibre (Br.); fibras de casina (Esp.); caseïnevezel (Ned); casein wool; caslen; Aralac; Lanital [Snia Viscosa, Italy]; Lactofil; Casolana; Tiolan; Polana; Cargan; Merinova; Fibrolan [Courtaulds, England]

Risks

Burns slowly and brightly in air, but extinguishes with removal of flame source.

Physical and Chemical Properties

Insoluble in dilute acids, hydrogen peroxide and most organic solvents. Affected by alkalis. Burns with odor of burning hair.

Filaments are smooth. Cross sections = circular, bean-shaped. Diameter=20-30 micrometers. Tenacity = 0.9-1.1 g/denier (dry); 0.3-0.6 (wet); Elongation =60-70%; Moisture regain = 14%; Melting Point = 150 C (dec); Density = 1.30 gm/cc

Resources and Citations

- Identification of Textile Materials, The Textile Institute, Manchester, England, 1985

- J.Gordon Cook, Handbook of Textile Fibres:II Man-made Fibres, Merrow Publishing Co. , Durham, England

- F. Kidd, Brushmaking Materials, Bristish Brush Manufacturers, London, 1957 Comment: p. 58

- Thomas Gregory, The Condensed Chemical Dictionary, Reinhold Publishing, New York, 3rd ed., 1942

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 153