Difference between revisions of "Mechanical wood pulp"

m (→Description) |

|||

| (6 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

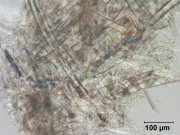

| − | [[File:98_Mechanical softwood_200X adj.jpg|thumb|Mechanical softwood]] | + | [[File:98_Mechanical softwood_200X adj.jpg|thumb|Mechanical softwood at 200x transmitted light]] |

== Description == | == Description == | ||

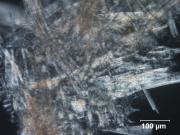

A mass of wood fibers produced by physically grinding rather than chemically treatment. To produce mechanical wood pulp, bark-free, cut wood is sent to a sandstone abrasion-type grinding machine. It is then screened and filtered to remove large pieces and foreign material. The resultant pulp contains [[lignin]], [[hemicellulose]], [[resin]], and colouring materials which yellow and deteriorate the paper over time. Thus, the pulp is often bleached with [[peroxide]] or hydrosulfite to improve whiteness. [[Groundwood paper]] is produced from coniferous trees. It is inexpensive and has low strength but high opacity and bulk. It is used for newsprint and other low cost printing papers. Groundwood paper is chemically unstable. | A mass of wood fibers produced by physically grinding rather than chemically treatment. To produce mechanical wood pulp, bark-free, cut wood is sent to a sandstone abrasion-type grinding machine. It is then screened and filtered to remove large pieces and foreign material. The resultant pulp contains [[lignin]], [[hemicellulose]], [[resin]], and colouring materials which yellow and deteriorate the paper over time. Thus, the pulp is often bleached with [[peroxide]] or hydrosulfite to improve whiteness. [[Groundwood paper]] is produced from coniferous trees. It is inexpensive and has low strength but high opacity and bulk. It is used for newsprint and other low cost printing papers. Groundwood paper is chemically unstable. | ||

| − | [[File:98_Mechanical softwood_200X_pol adj.jpg|thumb|Mechanical softwood]] | + | [[File:98_Mechanical softwood_200X_pol adj.jpg|thumb|Mechanical softwood at 200x polarized light]] |

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

| Line 10: | Line 10: | ||

mechanical wood-pulp; groundwood pulp | mechanical wood-pulp; groundwood pulp | ||

| − | == | + | == Physical an Chemical Properties == |

| − | Tests used to determine the presence of mechanical wood pulp in a paper are: 1) [ | + | Tests used to determine the presence of mechanical wood pulp in a paper are: 1) [[iodine]]-[[zinc chloride]] test gives a positive yellow, 2) [[aniline sulfate]] turns yellow for positive, 3) [[paranitroaniline]] turns orange, 4) [[phloroglucinol]] turns red (Roberts and Etherington 1982), 5) and [[Graff "C" stain]] will turn yellow due the presence of lignin. |

| − | == Additional | + | == Additional Images == |

| − | + | <gallery> | |

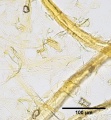

| + | File:SWGW 10x label.jpg|Softwood groundwood pulp stained with Graff "C" Stain at 10x | ||

| + | File:SWGW 40x label.jpg|Softwood groundwood pulp stained with Graff "C" Stain at 40x | ||

| + | </gallery> | ||

| − | == | + | ==Resources and Citations== |

* R. J. Gettens, G.L. Stout, ''Painting Materials, A Short Encyclopaedia'', Dover Publications, New York, 1966 | * R. J. Gettens, G.L. Stout, ''Painting Materials, A Short Encyclopaedia'', Dover Publications, New York, 1966 | ||

| Line 24: | Line 27: | ||

* Matt Roberts, Don Etherington, ''Bookbinding and the Conservation of Books: a Dictionary of Descriptive Terminology'', U.S. Government Printing Office, Washington DC, 1982 | * Matt Roberts, Don Etherington, ''Bookbinding and the Conservation of Books: a Dictionary of Descriptive Terminology'', U.S. Government Printing Office, Washington DC, 1982 | ||

| − | * ''Encyclopedia Britannica'', http://www.britannica.com Comment: "Papermaking." | + | * ''Encyclopedia Britannica'', http://www.britannica.com Comment: "Papermaking." Accessed 15 July 2004. |

| − | |||

| + | * Walter Rantanen. "Fiber ID Course." Integrated Paper Services. June 2013. Lecture. | ||

[[Category:Materials database]] | [[Category:Materials database]] | ||

Latest revision as of 14:52, 26 September 2022

Description

A mass of wood fibers produced by physically grinding rather than chemically treatment. To produce mechanical wood pulp, bark-free, cut wood is sent to a sandstone abrasion-type grinding machine. It is then screened and filtered to remove large pieces and foreign material. The resultant pulp contains Lignin, Hemicellulose, Resin, and colouring materials which yellow and deteriorate the paper over time. Thus, the pulp is often bleached with Peroxide or hydrosulfite to improve whiteness. Groundwood paper is produced from coniferous trees. It is inexpensive and has low strength but high opacity and bulk. It is used for newsprint and other low cost printing papers. Groundwood paper is chemically unstable.

Synonyms and Related Terms

mechanical wood-pulp; groundwood pulp

Physical an Chemical Properties

Tests used to determine the presence of mechanical wood pulp in a paper are: 1) Iodine-Zinc chloride test gives a positive yellow, 2) Aniline sulfate turns yellow for positive, 3) Paranitroaniline turns orange, 4) Phloroglucinol turns red (Roberts and Etherington 1982), 5) and Graff "C" stain will turn yellow due the presence of lignin.

Additional Images

Resources and Citations

- R. J. Gettens, G.L. Stout, Painting Materials, A Short Encyclopaedia, Dover Publications, New York, 1966

- Matt Roberts, Don Etherington, Bookbinding and the Conservation of Books: a Dictionary of Descriptive Terminology, U.S. Government Printing Office, Washington DC, 1982

- Encyclopedia Britannica, http://www.britannica.com Comment: "Papermaking." Accessed 15 July 2004.

- Walter Rantanen. "Fiber ID Course." Integrated Paper Services. June 2013. Lecture.