Difference between revisions of "Saran film"

| (8 intermediate revisions by the same user not shown) | |||

| Line 4: | Line 4: | ||

[SC Johnson] Originally a Dow Chemical tradename for thermoplastic film copolymer of [[polyvinylidene%20chloride|vinylidene chloride]] and small amounts of [[polyvinyl%20chloride|vinyl chloride]] or [[polyacrylonitrile|acrylonitrile]]. Polyvinylidene, or PVDC, was discovered by accident in 1933, by Ralph Wiley a college student working at Dow. The name Saran was trademarked by Dow Chemical in 1940, but has now become a commonly used name for thin plastic films used primarily to cover food. The PVDC films have a very low water permeability, is very inert and can withstand high temperatures. It has good chemical resistance to acids and alkalis and does not lose strength in sunlight. Saran plastic is used for fibers, packaging films and acid-resistant pipes. | [SC Johnson] Originally a Dow Chemical tradename for thermoplastic film copolymer of [[polyvinylidene%20chloride|vinylidene chloride]] and small amounts of [[polyvinyl%20chloride|vinyl chloride]] or [[polyacrylonitrile|acrylonitrile]]. Polyvinylidene, or PVDC, was discovered by accident in 1933, by Ralph Wiley a college student working at Dow. The name Saran was trademarked by Dow Chemical in 1940, but has now become a commonly used name for thin plastic films used primarily to cover food. The PVDC films have a very low water permeability, is very inert and can withstand high temperatures. It has good chemical resistance to acids and alkalis and does not lose strength in sunlight. Saran plastic is used for fibers, packaging films and acid-resistant pipes. | ||

| − | In 1998, the SC Johnson bought Saran Wrap from Dow. In 2004, due to environmental conserns, SCJ decided to remove chorine from all of their products. As a result, ' | + | In 1998, the SC Johnson bought Saran Wrap from Dow. In 2004, due to environmental conserns, SCJ decided to remove chorine from all of their products. As a result, 'Saran wrap' was reformulated as a linear low density [[polyethylene]] (LLDPE) film that is modified to contain some [[polybutylene]] as a cling agent. The polybutylene also allows the polyethylene to withstand higher temperatures, such as those produced by steam in a microwave. The reformulated product does not perform as well as PVDC, and the company lost significant sales due to the change, but the SJC CEO siad it was the right thing to do ([https://journaltimes.com/business/local/ceo-explains-why-sc-johnson-hobbled-saran-wrap/article_55000b9a-88cb-5786-a36e-3835f1d820ce.html Link]). |

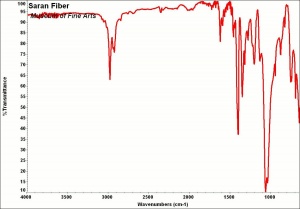

| − | + | [[[SliderGallery rightalign|Saran Fiber.jpg~FTIR of PVDC]]] | |

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

| + | Saran wrap; plastic wrap | ||

| + | Alternate names for LLDPE product: Saran Premium Wrap, Glad Cling Wrap, Handi-Wrap | ||

| − | + | == Applications == | |

| + | * PVDC was an efficient gas barrier and aa excellent barrier film against water vapor | ||

| + | * LLDPE has a limited lifetime, especially when stretched, and provides low gas barrier protection (Tetreault 2017) | ||

| − | == | + | == Personal Risks == |

| + | Nonflammable. | ||

| − | + | ==Collection Risks == | |

| − | + | == Physical and Chemical Properties == | |

| − | + | Resistant to acids, alkalis. May be damaged by ketone, carbon tetrachloride, ethanol, perchloroethylene. Resistant to insects and bacteria. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | == | + | For 1 mil film: |

| + | *Oxygen transmission = 12-16 ml/m2d | ||

| + | *Water vapor transmission = 3.8 g/m2d | ||

| + | *Melting Point = 160--177 C | ||

| + | *Density = 1.17 | ||

| − | + | == Resources and Citations == | |

| − | |||

| − | == | ||

| − | |||

| − | |||

| − | |||

| − | |||

| + | * SC Johnson: [https://www.scjohnson.com/en/our-products/ Website] | ||

| + | * The History of Saran Wrap: [http://inventors.about.com/library/inventors/blsaranwrap.htm Website] | ||

| + | * Jean Tetreault ''Products Used in Preventive Conservation'' CCI, December 2017. [https://www.researchgate.net/publication/323153775_Products_Used_in_Preventive_Conservation Link] | ||

* G.S.Brady, ''Materials Handbook'', McGraw-Hill Book Co., New York, 1971 Comment: p. 850 | * G.S.Brady, ''Materials Handbook'', McGraw-Hill Book Co., New York, 1971 Comment: p. 850 | ||

| − | |||

* Rosalie Rosso King, ''Textile Identification, Conservation, and Preservation'', Noyes Publications, Park Ridge, NJ, 1985 | * Rosalie Rosso King, ''Textile Identification, Conservation, and Preservation'', Noyes Publications, Park Ridge, NJ, 1985 | ||

| − | |||

* Pam Hatchfield, ''Pollutants in the Museum Environment'', Archetype Press, London, 2002 | * Pam Hatchfield, ''Pollutants in the Museum Environment'', Archetype Press, London, 2002 | ||

| − | + | * Wikipedia: http://en.wikipedia.org/wiki/Saran_%28plastic%29 (Accessed Sept. 14, 2005) | |

| − | * Wikipedia | ||

[[Category:Materials database]] | [[Category:Materials database]] | ||

Revision as of 14:23, 2 October 2024

Description

[SC Johnson] Originally a Dow Chemical tradename for thermoplastic film copolymer of vinylidene chloride and small amounts of vinyl chloride or acrylonitrile. Polyvinylidene, or PVDC, was discovered by accident in 1933, by Ralph Wiley a college student working at Dow. The name Saran was trademarked by Dow Chemical in 1940, but has now become a commonly used name for thin plastic films used primarily to cover food. The PVDC films have a very low water permeability, is very inert and can withstand high temperatures. It has good chemical resistance to acids and alkalis and does not lose strength in sunlight. Saran plastic is used for fibers, packaging films and acid-resistant pipes.

In 1998, the SC Johnson bought Saran Wrap from Dow. In 2004, due to environmental conserns, SCJ decided to remove chorine from all of their products. As a result, 'Saran wrap' was reformulated as a linear low density Polyethylene (LLDPE) film that is modified to contain some Polybutylene as a cling agent. The polybutylene also allows the polyethylene to withstand higher temperatures, such as those produced by steam in a microwave. The reformulated product does not perform as well as PVDC, and the company lost significant sales due to the change, but the SJC CEO siad it was the right thing to do (Link).

Synonyms and Related Terms

Saran wrap; plastic wrap

Alternate names for LLDPE product: Saran Premium Wrap, Glad Cling Wrap, Handi-Wrap

Applications

- PVDC was an efficient gas barrier and aa excellent barrier film against water vapor

- LLDPE has a limited lifetime, especially when stretched, and provides low gas barrier protection (Tetreault 2017)

Personal Risks

Nonflammable.

Collection Risks

Physical and Chemical Properties

Resistant to acids, alkalis. May be damaged by ketone, carbon tetrachloride, ethanol, perchloroethylene. Resistant to insects and bacteria.

For 1 mil film:

- Oxygen transmission = 12-16 ml/m2d

- Water vapor transmission = 3.8 g/m2d

- Melting Point = 160--177 C

- Density = 1.17

Resources and Citations

- SC Johnson: Website

- The History of Saran Wrap: Website

- Jean Tetreault Products Used in Preventive Conservation CCI, December 2017. Link

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 850

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985

- Pam Hatchfield, Pollutants in the Museum Environment, Archetype Press, London, 2002

- Wikipedia: http://en.wikipedia.org/wiki/Saran_%28plastic%29 (Accessed Sept. 14, 2005)