Difference between revisions of "Modacrylic fiber"

(username removed) |

|||

| (8 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

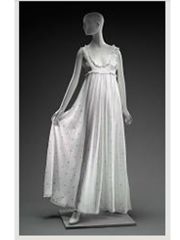

| + | [[File:MFA201261 Modacrylic.jpg|thumb|Modacrylic underlayers<br>MFA# 2012.61]] | ||

| + | == Description == | ||

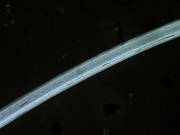

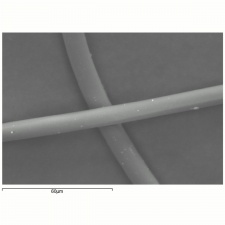

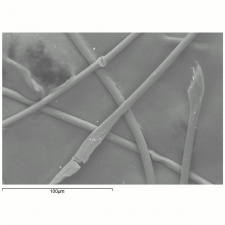

[[File:72 Teklan 200X pol.jpg|thumb|Teklan]] | [[File:72 Teklan 200X pol.jpg|thumb|Teklan]] | ||

| − | |||

| − | |||

A manufactured fiber in which the fiber-forming substance is any long chain synthetic polymer composed of less than 85% but at least 35% by weight of acrylonitrile units (Federal Trade Commission definition). The first modacrylic (modified acrylic) fiber, Dynel® was introduced in 1949; many later followed but the only one still in production at the end of the twentieth century is SEF [Solutia]. The resilient modacrylic fibers have an irregular cross section and fair elastic recovery (79-99% at 2% elongation). SEF has a low moisture regain of 2.5%. It will maintain its properties to temperatures of 190C (375F). Modacrylic fibers are resistant to sunlight, bleaches and are considered non-allergenic. Because modacrylic fibers are fire resistant and self-extinguishing, they are commonly used in children's sleepwear. They are also used for wigs, stuffed toys and fake fur fabrics. | A manufactured fiber in which the fiber-forming substance is any long chain synthetic polymer composed of less than 85% but at least 35% by weight of acrylonitrile units (Federal Trade Commission definition). The first modacrylic (modified acrylic) fiber, Dynel® was introduced in 1949; many later followed but the only one still in production at the end of the twentieth century is SEF [Solutia]. The resilient modacrylic fibers have an irregular cross section and fair elastic recovery (79-99% at 2% elongation). SEF has a low moisture regain of 2.5%. It will maintain its properties to temperatures of 190C (375F). Modacrylic fibers are resistant to sunlight, bleaches and are considered non-allergenic. Because modacrylic fibers are fire resistant and self-extinguishing, they are commonly used in children's sleepwear. They are also used for wigs, stuffed toys and fake fur fabrics. | ||

| − | |||

[[File:72 Teklan 200X.jpg|thumb|Teklan]] | [[File:72 Teklan 200X.jpg|thumb|Teklan]] | ||

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

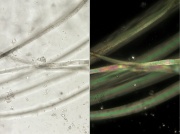

| − | + | [[File:Verel 200X BF.POL.jpg|thumb|Verel fibers]] | |

modacrylic fibre; polyacrylonitrile; Dynel® [Union Carbide]; Verel®[Tennessee Eastman]; SEF [Solutia]; Elura [Monsanto Fibers]; Teklan; Crylor; Kanecaron | modacrylic fibre; polyacrylonitrile; Dynel® [Union Carbide]; Verel®[Tennessee Eastman]; SEF [Solutia]; Elura [Monsanto Fibers]; Teklan; Crylor; Kanecaron | ||

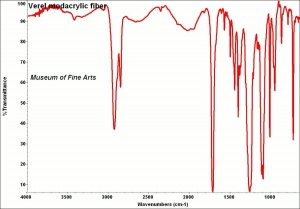

[[[SliderGallery rightalign|Verelfiberkj1.jpg~FTIR|verel1000m.jpg~SEM|verel350m.jpg~SEM]]] | [[[SliderGallery rightalign|Verelfiberkj1.jpg~FTIR|verel1000m.jpg~SEM|verel350m.jpg~SEM]]] | ||

| + | == Risks == | ||

| − | + | * Fire resistant and self-extinguishing. | |

| − | + | * Non-allergenic. | |

| − | + | * Cellusuede: [http://www.cellusuede.com/Images/SDS_modacrylic_2020rev.9-17.pdf Modacrylic SDS] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | == | + | == Physical and Chemical Properties == |

| − | + | * Soluble in butyrolactone and warm acetone. | |

| − | + | * Resistant to other organic solvents alkalis and acids. | |

| − | + | * Tenacity = 1.8-2.5 g/denier (dry); 1.7-2.4 (wet); | |

| − | + | * Elongation = 35-48%; | |

| − | = | + | * Moisture regain = 0.4-4.0%. |

| − | + | * Melting Point = 120-125C (soften). | |

| − | + | * Density = 1.35-1.37 | |

== Comparisons == | == Comparisons == | ||

| Line 40: | Line 31: | ||

[[media:download_file_53.pdf|Fiber Burn Tests]] | [[media:download_file_53.pdf|Fiber Burn Tests]] | ||

| − | + | == Resources and Citations == | |

| − | |||

| − | == | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

* Hoechst Celanese Corporation, ''Dictionary of Fiber & Textile Technology'' (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990 | * Hoechst Celanese Corporation, ''Dictionary of Fiber & Textile Technology'' (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990 | ||

| Line 61: | Line 43: | ||

* J.Gordon Cook, ''Handbook of Textile Fibres:II Man-made Fibres'', Merrow Publishing Co. , Durham, England | * J.Gordon Cook, ''Handbook of Textile Fibres:II Man-made Fibres'', Merrow Publishing Co. , Durham, England | ||

| − | * Website | + | * Website: www.fabrics.net |

* Rosalie Rosso King, ''Textile Identification, Conservation, and Preservation'', Noyes Publications, Park Ridge, NJ, 1985 | * Rosalie Rosso King, ''Textile Identification, Conservation, and Preservation'', Noyes Publications, Park Ridge, NJ, 1985 | ||

Latest revision as of 07:31, 27 September 2022

Description

A manufactured fiber in which the fiber-forming substance is any long chain synthetic polymer composed of less than 85% but at least 35% by weight of acrylonitrile units (Federal Trade Commission definition). The first modacrylic (modified acrylic) fiber, Dynel® was introduced in 1949; many later followed but the only one still in production at the end of the twentieth century is SEF [Solutia]. The resilient modacrylic fibers have an irregular cross section and fair elastic recovery (79-99% at 2% elongation). SEF has a low moisture regain of 2.5%. It will maintain its properties to temperatures of 190C (375F). Modacrylic fibers are resistant to sunlight, bleaches and are considered non-allergenic. Because modacrylic fibers are fire resistant and self-extinguishing, they are commonly used in children's sleepwear. They are also used for wigs, stuffed toys and fake fur fabrics.

Synonyms and Related Terms

modacrylic fibre; polyacrylonitrile; Dynel® [Union Carbide]; Verel®[Tennessee Eastman]; SEF [Solutia]; Elura [Monsanto Fibers]; Teklan; Crylor; Kanecaron

Risks

- Fire resistant and self-extinguishing.

- Non-allergenic.

- Cellusuede: Modacrylic SDS

Physical and Chemical Properties

- Soluble in butyrolactone and warm acetone.

- Resistant to other organic solvents alkalis and acids.

- Tenacity = 1.8-2.5 g/denier (dry); 1.7-2.4 (wet);

- Elongation = 35-48%;

- Moisture regain = 0.4-4.0%.

- Melting Point = 120-125C (soften).

- Density = 1.35-1.37

Comparisons

Properties of Synthetic Fibers

Resources and Citations

- Hoechst Celanese Corporation, Dictionary of Fiber & Textile Technology (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990

- Marjory L. Joseph, Introductory Textile Science, Holt, Rinehart and Winston, Fort Worth, TX, 1986

- Identification of Textile Materials, The Textile Institute, Manchester, England, 1985

- Fairchild's Dictionary of Textiles, Phyllis G.Tortora, Robert S. Merkel (eds.), Fairchild Publications, New York City, 7th edition, 1996

- J.Gordon Cook, Handbook of Textile Fibres:II Man-made Fibres, Merrow Publishing Co. , Durham, England

- Website: www.fabrics.net

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985

- Random House, Webster's Encyclopedic Unabridged Dictionary of the English Language, Grammercy Book, New York, 1997

- The American Heritage Dictionary or Encarta, via Microsoft Bookshelf 98, Microsoft Corp., 1998