Difference between revisions of "Triacetate fiber"

(username removed) |

|||

| (7 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| + | [[File:Triacetate scarf MFA.jpg|thumb|Triacetate scarf<br>MFA# 2001.2388]] | ||

| + | == Description == | ||

[[File:triacetatefiberslarge.jpg|thumb|Triacetate fiber]] | [[File:triacetatefiberslarge.jpg|thumb|Triacetate fiber]] | ||

| − | + | A manufactured fiber produced from [[cellulose%20triacetate|cellulose triacetate]]. Cellulose triacetate was first developed by Schutzenberger in 1865. However, this early acetate was a tough hard [[plastic|plastic]] that contained high amounts of [[acid|acids]] and was only soluble in expensive chlorinated [[solvent|solvents]]. Thus, cellulose triacetate was not commercially viable until the mid-1950s when economical solvents became available. Triacetate is a durable fiber that is resistant to wrinkles, stains, chemicals, sunlight, insects, and moisture. It should not be dry-cleaned but is not degraded by normal laundering. It dries quickly in air or cool driers and maintains its shape without ironing. Triacetate is a crisp, firm fabric that is often used in [[taffeta|taffetas]] and [[suiting|suitings]]. It is used in drip-dry clothing, tablecloths, skirts, and slacks. It is often used in wool blends to increase washability and crease retention. A surface saponification finishing process, called S-Finishing, is often applied to triacetate fabrics to minimize static. | |

| − | + | See also [[acetate%20fiber|acetate fiber]]. | |

| − | |||

| − | See also [ | ||

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

| Line 11: | Line 11: | ||

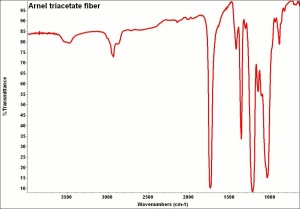

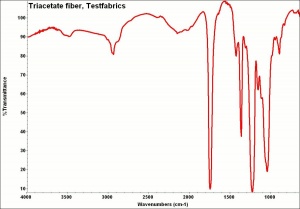

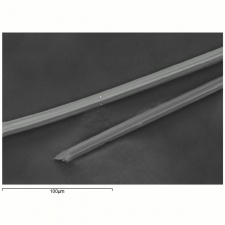

[[[SliderGallery rightalign|Arnelfiberkj1.jpg~FTIR|TriacetateTestfabrics.jpg~FTIR|arnel500m.jpg~SEM]]] | [[[SliderGallery rightalign|Arnelfiberkj1.jpg~FTIR|TriacetateTestfabrics.jpg~FTIR|arnel500m.jpg~SEM]]] | ||

| − | + | == Risks == | |

| − | == | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Subject to static cling | Subject to static cling | ||

| + | == Physical and Chemical Properties == | ||

| − | + | *Soluble in chloroform, methylene chloride, m-cresol, 90% phenol | |

| − | + | *Insoluble in acetone | |

| − | + | *Unaffected by dilute acids, alkalis and bleaches | |

| + | *Cross section is bulbous; fiber has longitudinal striations | ||

| + | *Tenacity = 1.1-1.4 g/denier (dry); 0.7-0.8 g/denier (wet) | ||

| + | *Elongation 25-35% (dry); 30-40% (wet) | ||

| + | *Moisture regain = 2.5-3.5% | ||

| + | *CAS# = 9012-09-3 | ||

| + | *Melting Point = 300 | ||

| + | *Density = 1.32 | ||

== Comparisons == | == Comparisons == | ||

| Line 40: | Line 31: | ||

[[media:download_file_44.pdf|Properties of Synthetic Fibers]] | [[media:download_file_44.pdf|Properties of Synthetic Fibers]] | ||

| − | + | == Resources and Citations == | |

| − | |||

| − | == | ||

* Hoechst Celanese Corporation, ''Dictionary of Fiber & Textile Technology'' (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990 | * Hoechst Celanese Corporation, ''Dictionary of Fiber & Textile Technology'' (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990 | ||

| Line 52: | Line 41: | ||

* ''Identification of Textile Materials'', The Textile Institute, Manchester, England, 1985 | * ''Identification of Textile Materials'', The Textile Institute, Manchester, England, 1985 | ||

| − | * J.Gordon Cook, ''Handbook of Textile Fibres:II Man-made Fibres'', Merrow Publishing Co. , Durham, England | + | * J.Gordon Cook, ''Handbook of Textile Fibres:II Man-made Fibres'', Merrow Publishing Co. , Durham, England, 1984, p.99. |

| − | * Wikipedia | + | * Wikipedia: http://en.wikipedia.org/wiki/Triacetate (Accessed Nov. 9, 2005) |

* ''Van Nostrand's Scientific Encyclopedia'', Douglas M. Considine (ed.), Van Nostrand Reinhold, New York, 1976 | * ''Van Nostrand's Scientific Encyclopedia'', Douglas M. Considine (ed.), Van Nostrand Reinhold, New York, 1976 | ||

Latest revision as of 13:26, 5 December 2020

Description

A manufactured fiber produced from Cellulose triacetate. Cellulose triacetate was first developed by Schutzenberger in 1865. However, this early acetate was a tough hard Plastic that contained high amounts of acids and was only soluble in expensive chlorinated solvents. Thus, cellulose triacetate was not commercially viable until the mid-1950s when economical solvents became available. Triacetate is a durable fiber that is resistant to wrinkles, stains, chemicals, sunlight, insects, and moisture. It should not be dry-cleaned but is not degraded by normal laundering. It dries quickly in air or cool driers and maintains its shape without ironing. Triacetate is a crisp, firm fabric that is often used in taffetas and suitings. It is used in drip-dry clothing, tablecloths, skirts, and slacks. It is often used in wool blends to increase washability and crease retention. A surface saponification finishing process, called S-Finishing, is often applied to triacetate fabrics to minimize static.

See also Acetate fiber.

Synonyms and Related Terms

triacetate fibre; Arnel® [Celanese, America]; Tricel [British Celanese]; Trilan; primary acetate; JPS [Courtaulds]; Courpleta [Courtaulds];fibra de triacetato(Esp.)

Risks

Subject to static cling

Physical and Chemical Properties

- Soluble in chloroform, methylene chloride, m-cresol, 90% phenol

- Insoluble in acetone

- Unaffected by dilute acids, alkalis and bleaches

- Cross section is bulbous; fiber has longitudinal striations

- Tenacity = 1.1-1.4 g/denier (dry); 0.7-0.8 g/denier (wet)

- Elongation 25-35% (dry); 30-40% (wet)

- Moisture regain = 2.5-3.5%

- CAS# = 9012-09-3

- Melting Point = 300

- Density = 1.32

Comparisons

Properties of Synthetic Fibers

Resources and Citations

- Hoechst Celanese Corporation, Dictionary of Fiber & Textile Technology (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985

- Marjory L. Joseph, Introductory Textile Science, Holt, Rinehart and Winston, Fort Worth, TX, 1986

- Identification of Textile Materials, The Textile Institute, Manchester, England, 1985

- J.Gordon Cook, Handbook of Textile Fibres:II Man-made Fibres, Merrow Publishing Co. , Durham, England, 1984, p.99.

- Wikipedia: http://en.wikipedia.org/wiki/Triacetate (Accessed Nov. 9, 2005)

- Van Nostrand's Scientific Encyclopedia, Douglas M. Considine (ed.), Van Nostrand Reinhold, New York, 1976