Difference between revisions of "Acetate fiber"

JLBoutaine (talk | contribs) |

|||

| (5 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | [[File:1993.653c-SC22239.jpg|thumb|' | + | [[File:1993.653c-SC22239.jpg|thumb|Women's costume<br>MFA# 1993.653c]] |

== Description == | == Description == | ||

| − | + | [[File:Acetate Rayon MFA.jpg|thumb|Acetate rayon dress<br>MFA# 2009.4086]] | |

A synthetic fiber composed of [[cellulose%20diacetate|cellulose diacetate]]. Although cellulose acetate was prepared as early as 1865, the fabric was first marketed in the UK as an artificial silk called Celanese® in 1919. Cellulose acetate fibers are prepared by treating purified [[cellulose|cellulose]] (linters or wood pulp) with [[acetic%20acid|acetic acid]] and [[acetic%20anhydride|acetic anhydride]]. Flakes of cellulose acetate are produced, dissolved in acetone and extruded through spinnerets to obtain solid, continuous filaments of cellulose acetate. Two types of acetate, triacetate and diacetate, are available with the diacetate being the most common. The diacetate fiber is officially called acetate while the [[cellulose%20triacetate|cellulose triacetate]] is called triacetate. Acetate fibers are fast-drying, wrinkle resistant and soft. Although originally called rayon, cellulose acetate was separated from rayon and given its own category in 1952. It differs from rayon in that acetate has greater wet-strength and is more sensitive to high temperatures. Acetate fibers are used for lingerie, dresses, blouses, draperies, upholstery, carpets, umbrellas, and cigarette filters. | A synthetic fiber composed of [[cellulose%20diacetate|cellulose diacetate]]. Although cellulose acetate was prepared as early as 1865, the fabric was first marketed in the UK as an artificial silk called Celanese® in 1919. Cellulose acetate fibers are prepared by treating purified [[cellulose|cellulose]] (linters or wood pulp) with [[acetic%20acid|acetic acid]] and [[acetic%20anhydride|acetic anhydride]]. Flakes of cellulose acetate are produced, dissolved in acetone and extruded through spinnerets to obtain solid, continuous filaments of cellulose acetate. Two types of acetate, triacetate and diacetate, are available with the diacetate being the most common. The diacetate fiber is officially called acetate while the [[cellulose%20triacetate|cellulose triacetate]] is called triacetate. Acetate fibers are fast-drying, wrinkle resistant and soft. Although originally called rayon, cellulose acetate was separated from rayon and given its own category in 1952. It differs from rayon in that acetate has greater wet-strength and is more sensitive to high temperatures. Acetate fibers are used for lingerie, dresses, blouses, draperies, upholstery, carpets, umbrellas, and cigarette filters. | ||

| − | + | For identification of acetate fibers, see http://cameo.mfa.org/wiki/Category:FRIL:_Acetate | |

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

| Line 11: | Line 11: | ||

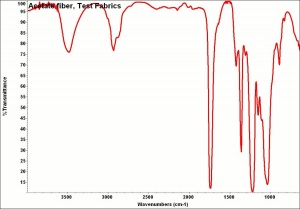

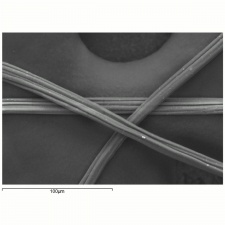

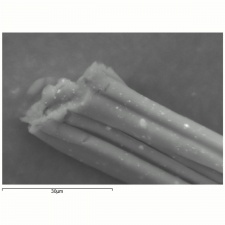

[[[SliderGallery rightalign|AcetatetestFabrics.jpg~FTIR|diacetate400m.jpg~SEM|diacetate2000m.jpg~SEM]]] | [[[SliderGallery rightalign|AcetatetestFabrics.jpg~FTIR|diacetate400m.jpg~SEM|diacetate2000m.jpg~SEM]]] | ||

| − | + | == Risks == | |

| − | == | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Degrades in sunlight. Burns readily. | Degrades in sunlight. Burns readily. | ||

Resistant to insects, slowly degraded by microorganisms. | Resistant to insects, slowly degraded by microorganisms. | ||

| + | == Physical and Chemical Properties == | ||

| − | == | + | Resistant to dilute alkalis and dry-cleaning solvents. Degrades in acids and concentrated alkalis. Soluble in acetone, alcohol, phenol and chloroform. Cross section has multiple lobes. Tenacity = 1.1-1.4 g/denier (dry); 0.65-0.75 g/den (wet); Elongation 25-35% (dry); 35-45% (wet); Moisture regain = 6.5%; Melting Point = 232; Density = 1.25-1.35; Refractive Index = 1.48 |

| − | + | Acetate burns readily with an unsteady flame that is difficult to extinguish by blowing. It smells like burnt wood. The ash is hard like melted plastic. | |

== Comparisons == | == Comparisons == | ||

| − | [[media: | + | [[media:download_file_46.pdf|Properties of Synthetic Fibers]] |

| − | |||

| − | |||

| − | |||

| + | [[media:download_file_47.pdf|Fiber Burn Tests]] | ||

== Additional Images == | == Additional Images == | ||

<gallery> | <gallery> | ||

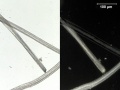

| + | File:Acetate 200X BF.POL.jpg|Acetate fibers | ||

File:acetatefiber1large.jpg|Acetate fiber | File:acetatefiber1large.jpg|Acetate fiber | ||

File:acetatefiberlarge.jpg|Acetate fiber | File:acetatefiberlarge.jpg|Acetate fiber | ||

</gallery> | </gallery> | ||

| − | + | == Resources and Citations == | |

| − | == | ||

* Hoechst Celanese Corporation, ''Dictionary of Fiber & Textile Technology'' (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990 | * Hoechst Celanese Corporation, ''Dictionary of Fiber & Textile Technology'' (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990 | ||

| Line 70: | Line 50: | ||

* Marjory L. Joseph, ''Introductory Textile Science'', Holt, Rinehart and Winston, Fort Worth, TX, 1986 | * Marjory L. Joseph, ''Introductory Textile Science'', Holt, Rinehart and Winston, Fort Worth, TX, 1986 | ||

| − | * | + | * History of plastics: [http://www.nswpmith.com.au/historyofplastics.html Link] First sold in UK in 1919 |

| − | * Wikipedia | + | * Wikipedia: http://en.wikipedia.org/wiki/Cellulose_acetate (Accessed Oct. 18, 2005) -first US commercial acetate fiber production in 1924, Celanese |

| − | * | + | * Olympus Microscopy Resource Center at http://www.olympusmicro.com/galleries/polarizedlight/pages/acetatefibersmall.html - attributes first acetate fibers to Camille and Henry Dreyfus in 1913. First sold in US in 1924 as Celanese. |

* Richard S. Lewis, ''Hawley's Condensed Chemical Dictionary'', Van Nostrand Reinhold, New York, 10th ed., 1993 | * Richard S. Lewis, ''Hawley's Condensed Chemical Dictionary'', Van Nostrand Reinhold, New York, 10th ed., 1993 | ||

| Line 80: | Line 60: | ||

* ''Van Nostrand's Scientific Encyclopedia'', Douglas M. Considine (ed.), Van Nostrand Reinhold, New York, 1976 | * ''Van Nostrand's Scientific Encyclopedia'', Douglas M. Considine (ed.), Van Nostrand Reinhold, New York, 1976 | ||

| − | * Website | + | * Website: www.fabrics.net |

[[Category:Materials database]] | [[Category:Materials database]] | ||

Latest revision as of 10:53, 19 October 2020

Description

A synthetic fiber composed of Cellulose diacetate. Although cellulose acetate was prepared as early as 1865, the fabric was first marketed in the UK as an artificial silk called Celanese® in 1919. Cellulose acetate fibers are prepared by treating purified Cellulose (linters or wood pulp) with Acetic acid and Acetic anhydride. Flakes of cellulose acetate are produced, dissolved in acetone and extruded through spinnerets to obtain solid, continuous filaments of cellulose acetate. Two types of acetate, triacetate and diacetate, are available with the diacetate being the most common. The diacetate fiber is officially called acetate while the Cellulose triacetate is called triacetate. Acetate fibers are fast-drying, wrinkle resistant and soft. Although originally called rayon, cellulose acetate was separated from rayon and given its own category in 1952. It differs from rayon in that acetate has greater wet-strength and is more sensitive to high temperatures. Acetate fibers are used for lingerie, dresses, blouses, draperies, upholstery, carpets, umbrellas, and cigarette filters.

For identification of acetate fibers, see http://cameo.mfa.org/wiki/Category:FRIL:_Acetate

Synonyms and Related Terms

acetate fibre (Br.); acétate; acétate de cellulose (Fr.) acetaatvezel (Ned); acetate rayon; acetate silk; Tenite®; Arnel®; artificial silk; Dicel; secondary acetate; Acele®; Celanese® [Celanese]; Chromspun® [Eastman Chemical]; Estron [Eastman Chemical]

Risks

Degrades in sunlight. Burns readily.

Resistant to insects, slowly degraded by microorganisms.

Physical and Chemical Properties

Resistant to dilute alkalis and dry-cleaning solvents. Degrades in acids and concentrated alkalis. Soluble in acetone, alcohol, phenol and chloroform. Cross section has multiple lobes. Tenacity = 1.1-1.4 g/denier (dry); 0.65-0.75 g/den (wet); Elongation 25-35% (dry); 35-45% (wet); Moisture regain = 6.5%; Melting Point = 232; Density = 1.25-1.35; Refractive Index = 1.48

Acetate burns readily with an unsteady flame that is difficult to extinguish by blowing. It smells like burnt wood. The ash is hard like melted plastic.

Comparisons

Properties of Synthetic Fibers

Additional Images

Resources and Citations

- Hoechst Celanese Corporation, Dictionary of Fiber & Textile Technology (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990

- Fairchild's Dictionary of Textiles, Phyllis G.Tortora, Robert S. Merkel (eds.), Fairchild Publications, New York City, 7th edition, 1996 Comment: given own category by FTC in 1952

- J.Gordon Cook, Handbook of Textile Fibres:II Man-made Fibres, Merrow Publishing Co. , Durham, England

- S.R.Trotman, E.R. Trotman, Textile Analysis, J.B. Lippincott Company, Philadelphia, 1932

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985 Comment: Patented 1893; first marketed in UK 1921; first sold in US 1924; given own category in 1952.

- Marjory L. Joseph, Introductory Textile Science, Holt, Rinehart and Winston, Fort Worth, TX, 1986

- History of plastics: Link First sold in UK in 1919

- Wikipedia: http://en.wikipedia.org/wiki/Cellulose_acetate (Accessed Oct. 18, 2005) -first US commercial acetate fiber production in 1924, Celanese

- Olympus Microscopy Resource Center at http://www.olympusmicro.com/galleries/polarizedlight/pages/acetatefibersmall.html - attributes first acetate fibers to Camille and Henry Dreyfus in 1913. First sold in US in 1924 as Celanese.

- Richard S. Lewis, Hawley's Condensed Chemical Dictionary, Van Nostrand Reinhold, New York, 10th ed., 1993

- Van Nostrand's Scientific Encyclopedia, Douglas M. Considine (ed.), Van Nostrand Reinhold, New York, 1976

- Website: www.fabrics.net