Difference between revisions of "Nylon 11"

Jump to navigation

Jump to search

m (Text replace - "== Authority ==" to "== Sources Checked for Data in Record ==") |

|||

| (2 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

== Description == | == Description == | ||

| − | Nylon 11 is composed of polymerized 11-amino-undecanoic acid. Nylon 11 was originally made from [ | + | Nylon 11 is composed of polymerized 11-amino-undecanoic acid. Nylon 11 was originally made from [[castor%20oil|castor bean oil]] and marketed under the trademark of Rilsan®. Nylon 11 fibers have similar properties to nylon 6 and 6,6. Nylon 11, however is less dense, melts at a lower temperature and has better dimensional stability. It is often used for brush bristles, lingerie, bulked yarns, and injection molded plastics. |

| − | |||

| − | |||

| + | See also [[nylon%20fiber|nylon fiber]]. | ||

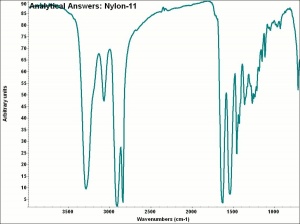

| + | [[[SliderGallery rightalign|aaiNYLON-11.jpg~FTIR]]] | ||

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

PA11; polyamide 11; polyundecanamide; Nylon® [Du Pont]; Rilsan® [Arkema]; Rilsanite® | PA11; polyamide 11; polyundecanamide; Nylon® [Du Pont]; Rilsan® [Arkema]; Rilsanite® | ||

| − | + | ==Physical and Chemical Properties== | |

| − | |||

| − | == | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | * Resistant to alkalis and most organic solvents. Degraded by concentrated acids and phenol. | |

| + | * Burns with yellow-orange flame and blue smoke; smells of burnt horn. | ||

| + | * Fiber is smooth. | ||

| + | * Cross section is circular. | ||

| + | * Tenacity = 5.0-7.5 g/denier (dry or wet); | ||

| + | * Elongation = 25% (dry or wet); | ||

| + | * Moisture regain = 1.18% | ||

| + | * Melting Point = 189 C | ||

| + | * Density = 1.04 g/ml | ||

| − | == | + | ==Resources and Citations== |

* G.S.Brady, ''Materials Handbook'', McGraw-Hill Book Co., New York, 1971 Comment: p. 553 | * G.S.Brady, ''Materials Handbook'', McGraw-Hill Book Co., New York, 1971 Comment: p. 553 | ||

| Line 37: | Line 30: | ||

* J.Gordon Cook, ''Handbook of Textile Fibres:II Man-made Fibres'', Merrow Publishing Co. , Durham, England | * J.Gordon Cook, ''Handbook of Textile Fibres:II Man-made Fibres'', Merrow Publishing Co. , Durham, England | ||

| − | |||

| − | |||

* F. Kidd, ''Brushmaking Materials'', Bristish Brush Manufacturers, London, 1957 | * F. Kidd, ''Brushmaking Materials'', Bristish Brush Manufacturers, London, 1957 | ||

Latest revision as of 12:53, 19 October 2022

Description

Nylon 11 is composed of polymerized 11-amino-undecanoic acid. Nylon 11 was originally made from castor bean oil and marketed under the trademark of Rilsan®. Nylon 11 fibers have similar properties to nylon 6 and 6,6. Nylon 11, however is less dense, melts at a lower temperature and has better dimensional stability. It is often used for brush bristles, lingerie, bulked yarns, and injection molded plastics.

See also Nylon fiber.

Synonyms and Related Terms

PA11; polyamide 11; polyundecanamide; Nylon® [Du Pont]; Rilsan® [Arkema]; Rilsanite®

Physical and Chemical Properties

- Resistant to alkalis and most organic solvents. Degraded by concentrated acids and phenol.

- Burns with yellow-orange flame and blue smoke; smells of burnt horn.

- Fiber is smooth.

- Cross section is circular.

- Tenacity = 5.0-7.5 g/denier (dry or wet);

- Elongation = 25% (dry or wet);

- Moisture regain = 1.18%

- Melting Point = 189 C

- Density = 1.04 g/ml

Resources and Citations

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 553

- Richard S. Lewis, Hawley's Condensed Chemical Dictionary, Van Nostrand Reinhold, New York, 10th ed., 1993

- Marjory L. Joseph, Introductory Textile Science, Holt, Rinehart and Winston, Fort Worth, TX, 1986

- J.Gordon Cook, Handbook of Textile Fibres:II Man-made Fibres, Merrow Publishing Co. , Durham, England

- F. Kidd, Brushmaking Materials, Bristish Brush Manufacturers, London, 1957