Difference between revisions of "Nomex"

| (40 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[File:NomexPACCIN.jpg|thumb|Nomex case lining]] | [[File:NomexPACCIN.jpg|thumb|Nomex case lining]] | ||

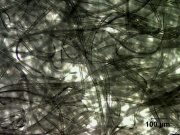

| + | [[File:25Nomexsoftwrap2100X.jpg|thumb|Nomex Softwrap]] | ||

== Description == | == Description == | ||

| − | |||

| − | |||

[[File:NomexfeltSI.jpg|thumb|Nomex felt used in astronaut spacesuits]] | [[File:NomexfeltSI.jpg|thumb|Nomex felt used in astronaut spacesuits]] | ||

| − | [[File: | + | [DuPont] A registered trademark for a meta-[[aramid_fiber|aramid fiber]] that was originally developed in the 60s for fire/electrical insulation applications. Nomex® fibers are composed of poly(m-phenylene isophthalamide), which is made from m-phenylene diamine and isophthalic acid. The fibers have excellent dielectric, thermal and mechanical properties and are resistant to fire, water, and biological growth. They retain their properties at temperatures up to 370C (700F). Nomex® fibers are available as both woven and nonwoven fabrics. Due to its fire resistance, Nomex® fabrics are used in fire fighters clothing, military flight suits and other applications in the space program. Soft forms of Nomex® are used for as a lining material in packing museum objects. Nomex® can also be laminated then expanded to form the lightweight core in [[honeycomb board|honeycomb structural boards]]. |

| + | [[File:66 Nomex nylon HT1 200X pol.jpg|thumb|Nomex]] | ||

| + | [[File:66 Nomex nylon HT1 200X.jpg|thumb|Nomex]] | ||

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

aramid; meta-aramid; Nomex Softwrap; Nomex Gentle Wrap | aramid; meta-aramid; Nomex Softwrap; Nomex Gentle Wrap | ||

| − | == | + | == Applications == |

| + | * Lining cavities cut in foam | ||

| + | * Can be sewn and bonded with hot melt adhesives without melting | ||

| + | |||

| + | == Personal Risks == | ||

| + | Nomex SDS [[https://hazard.com/msds/mf/dupont/nomex.html]] | ||

| − | + | == Collection Risks == | |

| − | + | May be susceptible to snagging on corners. | |

| − | + | == Environmental Risks == | |

| − | + | == Physical and Chemical Properties == | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | * Resistant to acids, alkalis, bleaches and most solvents. | |

| − | + | * Fiber is super-strong, yet smooth and soft; does not pill or fuzz. | |

| + | * Permeable to air and moisture. | ||

| + | * Fiber cross section = dogbone. | ||

| + | * Fire resistant and self-extinguishing. | ||

| + | * Degrades in ultraviolet light. | ||

| + | * Melting Point = 350 C (start of initial decomposition; the process is slow) | ||

| + | * Density = 1.38 g/ml | ||

| + | * Tenacity = 5.3 g/denier (dry) | ||

| + | * Elongation = 22% | ||

| + | * Moisture regain = 3.5% | ||

| − | == | + | == Working Properties == |

The spunwoven version of Nomex is typically used in museum applications. It has the unique ability to stretch in one direction, preventing bunching and folding of loose material within a cavity [http://www.paccin.org/content.php?62-Materials (PACCIN)]. | The spunwoven version of Nomex is typically used in museum applications. It has the unique ability to stretch in one direction, preventing bunching and folding of loose material within a cavity [http://www.paccin.org/content.php?62-Materials (PACCIN)]. | ||

| − | + | == Forms/Sizes == | |

| − | + | Forms include fibers, paper/fabric, felts, and rigid honeycomb boards. | |

| − | |||

| − | |||

| − | == Forms | ||

| − | |||

Flexible fabric typically comes rolls with widths of 39”. Thicknesses range from 3 to 30 mils. | Flexible fabric typically comes rolls with widths of 39”. Thicknesses range from 3 to 30 mils. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

== Comparisons == | == Comparisons == | ||

| Line 58: | Line 45: | ||

[[media:download_file_59.pdf|Properties of Synthetic Fibers]] | [[media:download_file_59.pdf|Properties of Synthetic Fibers]] | ||

| − | == | + | == Resources and Citations == |

| + | * DuPont: [https://www.dupont.com/brands/nomex.html Nomex Website] | ||

* Preparation, Art Handling, Collections Care Information Network [http://www.paccin.org/content.php?62-Materials (PACCIN)] | * Preparation, Art Handling, Collections Care Information Network [http://www.paccin.org/content.php?62-Materials (PACCIN)] | ||

| − | + | * Random House, ''Webster's Encyclopedic Unabridged Dictionary of the English Language'', Grammercy Book, New York, 1997 | |

| − | * | + | * Rosalie Rosso King, ''Textile Identification, Conservation, and Preservation'', Noyes Publications, Park Ridge, NJ, 1985 |

| − | + | * Marjory L. Joseph, ''Introductory Textile Science'', Holt, Rinehart and Winston, Fort Worth, TX, 1986 | |

| − | * | + | * Gordon Hanlon, contributed information, 1998 |

| − | + | * Meredith Montague, contributed information, 1998 | |

| − | * | + | * Theodore J. Reinhart, 'Glossary of Terms', ''Engineered Plastics'', ASM International, 1988 |

| − | + | * Website: www.textileworld.com/categories/9905/fibers/html | |

| − | * | ||

| − | |||

| − | * | ||

| − | |||

| − | * | ||

| − | |||

| − | * Website | ||

| − | [[Category:Materials database]] [[Category:MWG]] [[Category:PACCIN]] | + | [[Category:Materials database]] [[Category:MWG]] [[Category:PACCIN]][[Category:Sheet, Fabric]][[Category: Interleaving]] |

Latest revision as of 14:54, 9 February 2025

Description

[DuPont] A registered trademark for a meta-Aramid fiber that was originally developed in the 60s for fire/electrical insulation applications. Nomex® fibers are composed of poly(m-phenylene isophthalamide), which is made from m-phenylene diamine and isophthalic acid. The fibers have excellent dielectric, thermal and mechanical properties and are resistant to fire, water, and biological growth. They retain their properties at temperatures up to 370C (700F). Nomex® fibers are available as both woven and nonwoven fabrics. Due to its fire resistance, Nomex® fabrics are used in fire fighters clothing, military flight suits and other applications in the space program. Soft forms of Nomex® are used for as a lining material in packing museum objects. Nomex® can also be laminated then expanded to form the lightweight core in honeycomb structural boards.

Synonyms and Related Terms

aramid; meta-aramid; Nomex Softwrap; Nomex Gentle Wrap

Applications

- Lining cavities cut in foam

- Can be sewn and bonded with hot melt adhesives without melting

Personal Risks

Nomex SDS [[1]]

Collection Risks

May be susceptible to snagging on corners.

Environmental Risks

Physical and Chemical Properties

- Resistant to acids, alkalis, bleaches and most solvents.

- Fiber is super-strong, yet smooth and soft; does not pill or fuzz.

- Permeable to air and moisture.

- Fiber cross section = dogbone.

- Fire resistant and self-extinguishing.

- Degrades in ultraviolet light.

- Melting Point = 350 C (start of initial decomposition; the process is slow)

- Density = 1.38 g/ml

- Tenacity = 5.3 g/denier (dry)

- Elongation = 22%

- Moisture regain = 3.5%

Working Properties

The spunwoven version of Nomex is typically used in museum applications. It has the unique ability to stretch in one direction, preventing bunching and folding of loose material within a cavity (PACCIN).

Forms/Sizes

Forms include fibers, paper/fabric, felts, and rigid honeycomb boards. Flexible fabric typically comes rolls with widths of 39”. Thicknesses range from 3 to 30 mils.

Comparisons

Properties of Synthetic Fibers

Resources and Citations

- DuPont: Nomex Website

- Preparation, Art Handling, Collections Care Information Network (PACCIN)

- Random House, Webster's Encyclopedic Unabridged Dictionary of the English Language, Grammercy Book, New York, 1997

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985

- Marjory L. Joseph, Introductory Textile Science, Holt, Rinehart and Winston, Fort Worth, TX, 1986

- Gordon Hanlon, contributed information, 1998

- Meredith Montague, contributed information, 1998

- Theodore J. Reinhart, 'Glossary of Terms', Engineered Plastics, ASM International, 1988

- Website: www.textileworld.com/categories/9905/fibers/html