Difference between revisions of "Polyacrylonitrile"

| (One intermediate revision by the same user not shown) | |||

| Line 3: | Line 3: | ||

A polymer made from the addition polymerization of [[acrylonitrile|acrylonitrile]]. Polyacrylonitrile was first made in the late 1930s and it quickly became an important types of [[rubber (synthetic)|synthetic rubber]]. During W.W.II, polyacrylonitrile was made into fibers for military use. After the war, DuPont began to commercially produce acrylonitrile fibers under the brand name of Orlon® in 1950. Initially all acrylonitrile fibers were called acrylic fibers. As processing variations developed, the FTC divided the types of fibers into the following two classes: | A polymer made from the addition polymerization of [[acrylonitrile|acrylonitrile]]. Polyacrylonitrile was first made in the late 1930s and it quickly became an important types of [[rubber (synthetic)|synthetic rubber]]. During W.W.II, polyacrylonitrile was made into fibers for military use. After the war, DuPont began to commercially produce acrylonitrile fibers under the brand name of Orlon® in 1950. Initially all acrylonitrile fibers were called acrylic fibers. As processing variations developed, the FTC divided the types of fibers into the following two classes: | ||

| − | + | * Acrylic fibers - contain at least 85% acrylonitrile units | |

| − | + | * Modacrylic fibers - contain 35-85 % acrylonitrile units. Pure polyacrylonitrile is also used for moldings, shoe soling and wall panels. | |

| − | |||

See [[acrylic%20fiber|acrylic fiber]], and [[modacrylic%20fiber|modacrylic fiber]]. | See [[acrylic%20fiber|acrylic fiber]], and [[modacrylic%20fiber|modacrylic fiber]]. | ||

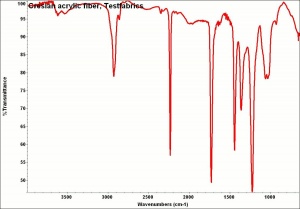

| − | + | [[[SliderGallery rightalign|CreslanTestfabrics.jpg~FTIR]]] | |

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

| Line 14: | Line 13: | ||

Examples: Fiber A; Orlon® [DuPont]; Acrilan® [Solutia]; Dynel® [Union Carbide]; Courtelle® [Courtaulds]; | Examples: Fiber A; Orlon® [DuPont]; Acrilan® [Solutia]; Dynel® [Union Carbide]; Courtelle® [Courtaulds]; | ||

| − | |||

| − | |||

== Physical and Chemical Properties == | == Physical and Chemical Properties == | ||

| − | Soluble in dimethylformamide, dimethylsulfoxide. Insoluble in alcohols, diethyl ether, water, hydrocarbons. | + | * Soluble in dimethylformamide, dimethylsulfoxide. |

| − | + | * Insoluble in alcohols, diethyl ether, water, hydrocarbons. | |

| − | + | * Density = 1.14-1.17 g/ml | |

| − | |||

| − | |||

| − | |||

| − | |||

== Comparisons == | == Comparisons == | ||

| Line 42: | Line 35: | ||

* J.Gordon Cook, ''Handbook of Textile Fibres:II Man-made Fibres'', 5th edition, Merrow Publishing Co., Durham, England, 1984, p393. | * J.Gordon Cook, ''Handbook of Textile Fibres:II Man-made Fibres'', 5th edition, Merrow Publishing Co., Durham, England, 1984, p393. | ||

| + | |||

* Art and Architecture Thesaurus Online, http://www.getty.edu/research/tools/vocabulary/aat/, J. Paul Getty Trust, Los Angeles, 2000 | * Art and Architecture Thesaurus Online, http://www.getty.edu/research/tools/vocabulary/aat/, J. Paul Getty Trust, Los Angeles, 2000 | ||

Latest revision as of 12:18, 22 October 2022

Description

A polymer made from the addition polymerization of Acrylonitrile. Polyacrylonitrile was first made in the late 1930s and it quickly became an important types of synthetic rubber. During W.W.II, polyacrylonitrile was made into fibers for military use. After the war, DuPont began to commercially produce acrylonitrile fibers under the brand name of Orlon® in 1950. Initially all acrylonitrile fibers were called acrylic fibers. As processing variations developed, the FTC divided the types of fibers into the following two classes:

- Acrylic fibers - contain at least 85% acrylonitrile units

- Modacrylic fibers - contain 35-85 % acrylonitrile units. Pure polyacrylonitrile is also used for moldings, shoe soling and wall panels.

See Acrylic fiber, and Modacrylic fiber.

Synonyms and Related Terms

PAN; poliacrilonitrilo (Esp.); polyacrylonitrile (Fr.); poliacrilonitrile (It.); poliacrilonitrilo (Port.); polyvinyl cyanide

Examples: Fiber A; Orlon® [DuPont]; Acrilan® [Solutia]; Dynel® [Union Carbide]; Courtelle® [Courtaulds];

Physical and Chemical Properties

- Soluble in dimethylformamide, dimethylsulfoxide.

- Insoluble in alcohols, diethyl ether, water, hydrocarbons.

- Density = 1.14-1.17 g/ml

Comparisons

Properties of Synthetic Fibers

Resources and Citations

- Theodore J. Reinhart, 'Glossary of Terms', Engineered Plastics, ASM International, 1988

- Richard S. Lewis, Hawley's Condensed Chemical Dictionary, Van Nostrand Reinhold, New York, 10th ed., 1993

- Pam Hatchfield, Pollutants in the Museum Environment, Archetype Press, London, 2002

- Random House, Webster's Encyclopedic Unabridged Dictionary of the English Language, Grammercy Book, New York, 1997

- J.Gordon Cook, Handbook of Textile Fibres:II Man-made Fibres, 5th edition, Merrow Publishing Co., Durham, England, 1984, p393.

- Art and Architecture Thesaurus Online, http://www.getty.edu/research/tools/vocabulary/aat/, J. Paul Getty Trust, Los Angeles, 2000