Difference between revisions of "Gray cast iron"

Jump to navigation

Jump to search

m (Text replace - "== Authority ==" to "== Sources Checked for Data in Record ==") |

|||

| Line 16: | Line 16: | ||

The seasoning or impregnation of cast iron cookware with oil minimizes rusting. | The seasoning or impregnation of cast iron cookware with oil minimizes rusting. | ||

| − | == | + | == Sources Checked for Data in Record == |

* David C. Scott, ''Metallography and Microstructure of Ancient and Historic Metals'', The Getty Conservation Institute, Los Angeles, 1991 | * David C. Scott, ''Metallography and Microstructure of Ancient and Historic Metals'', The Getty Conservation Institute, Los Angeles, 1991 | ||

Revision as of 21:15, 30 April 2016

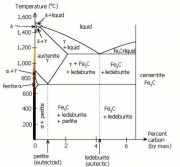

Description

A hard, brittle Cast iron that contains 1-3% Silicon in addition to the Carbon. In grey cast iron, the silicon causes the carbon to come out of solution as Graphite. The small flakes of graphite imbedded in the ferrite matrix make the alloy flow easily when melted; the resultant iron alloy is softer and has good corrosion and wear resistance. Gray cast iron is extremely brittle and can shatter when struck.

Synonyms and Related Terms

gray iron; grey cast iron (Br.); fonte grise (Fr.); Grauguß (Deut.); grijs gietijzer (Ned.); ferro fundido cinzento (Port.)

Other Properties

Gray cast iron has less tesiile strength and shock resistance than steel. It is difficult to weld.

The seasoning or impregnation of cast iron cookware with oil minimizes rusting.

Sources Checked for Data in Record

- David C. Scott, Metallography and Microstructure of Ancient and Historic Metals, The Getty Conservation Institute, Los Angeles, 1991

- Dictionary of Building Preservation, Ward Bucher, ed., John Wiley & Sons, Inc., New York City, 1996

- Website address 1 Comment: Olympus Microscopy Resource Center at http://www.olympusmicro.com/galleries/abramowitz/pages/graycastironsmall.html

- Wikipedia, the free encyclopedia, at http://www.wikipedia.com Comment: http://en.wikipedia.org/wiki/Cast_iron (Accessed Oct. 18, 2005)