Cast iron

Description

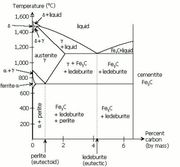

An alloy of Iron with Carbon that is hard, brittle and nonmalleable. Cast iron contains about 2 to 4% Carbon and 1 to 3% Silicon. It was made in China by at least the 3rd century BCE. The technique for its production did not reach Europe until medieval times. Cast iron is manufactured by melting scrap iron or pig iron in a cupola that is in contact with the coal fuel, then casting the molten iron into a mold. It is inexpensive and easy to make. In the 1830s, cast iron was used for structural and decorative building components in North America. It was also used for cast iron pipe, stove pipe, firebacks, cauldrons, and cannons.

Synonyms and Related Terms

gray cast iron; white cast iron; grey cast iron; Gusseisen (Deut.); fonte (Fr.); gietijzer (Ned.); gjutjärn (Sven.); hierro fundido (Esp.); ferro fundido (Port.)

Comparison Table

| Name | Nominal composition [% by weight] |

Form and condition | Yield strength [ksi; 0.2% offset)] |

Tensile strength [ksi] | Elongation [%] | Hardness [Brinell scale] | Uses |

|---|---|---|---|---|---|---|---|

| Gray cast iron (ASTM A48) | C 3.4, Si 1.8, Mn 0.5 | Cast | — | 50 | 0.5 | 260 | , cylinder blocks, flywheels, gearbox cases, machine-tool bases |

| White cast iron | C 3.4, Si 0.7, Mn 0.6 | Cast (as cast) | — | 25 | 0 | 450 | Bearing (mechanical) surfaces |

| Malleable iron (ASTM A47) | C 2.5, Si 1.0, Mn 0.55 | Cast (annealed) | 33 | 52 | 12 | 130 | Axle bearings, track wheels, automotive crankshafts |

| Ductile or nodular iron | C 3.4, P 0.1, Mn 0.4, Ni 1.0, Mg 0.06 | Cast | 53 | 70 | 18 | 170 | Gears, camshafts, crankshafts |

| Ductile or nodular iron (ASTM A339) | — | Cast (quench tempered) | 108 | 135 | 5 | 310 | — |

| Ni-hard type 2 | C 2.7, Si 0.6, Mn 0.5, Ni 4.5, Cr 2.0 | Sand-cast | — | 55 | — | 550 | High strength applications |

| Ni-resist type 2 | C 3.0, Si 2.0, Mn 1.0, Ni 20.0, Cr 2.5 | Cast | — | 27 | 2 | 140 | Resistance to heat and corrosion |

Working Properties

- Gray cast iron (with silicon) has less tensile strength and shock resistance than steel. It is difficult to weld.

- The seasoning or impregnation of cast iron cookware with oil minimizes rusting.

Resources and Citations

- David C. Scott, Metallography and Microstructure of Ancient and Historic Metals, The Getty Conservation Institute, Los Angeles, 1991 Comment: usually 2-4 % carbon

- Dictionary of Building Preservation, Ward Bucher, ed., John Wiley & Sons, Inc., New York City, 1996 Comment: 2.5-4.0% carbon

- The Dictionary of Art, Grove's Dictionaries Inc., New York, 1996

- Wikipedia: Cast iron (Accessed Oct. 18, 2005 and March 2025): 1.8-4 % carbon, 1-3% silicon

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 155

- Richard S. Lewis, Hawley's Condensed Chemical Dictionary, Van Nostrand Reinhold, New York, 10th ed., 1993

- Henry Hodges, Artifacts: An Introduction to Early Materials and Technology, Ronald P. Frye, Kingston, Canada, 1988

- Random House, Webster's Encyclopedic Unabridged Dictionary of the English Language, Grammercy Book, New York, 1997

- The American Heritage Dictionary or Encarta, via Microsoft Bookshelf 98, Microsoft Corp., 1998 Comment: 2.0-4.5% carbon, 0.5-3.0% silicon

- Susan E. Schur, Conservation Terminology: A review of Past & Current Nomenclature of Materials, Technology and Conservation, Spring (p.34-39); Summer (p.35-38); Fall (p.25-36), 1985

- Cast iron at www.answers.com; 2.0-3.5% carbon, 1-3% silicon

- ↑ Lyons, William C. and Plisga, Gary J. (eds.) Standard Handbook of Petroleum & Natural Gas Engineering, Elsevier, 2006