Difference between revisions of "Phenol formaldehyde resin"

m (Text replace - "== Authority ==" to "== Sources Checked for Data in Record ==") |

m (Text replace - "\[http:\/\/cameo\.mfa\.org\/materials\/fullrecord\.asp\?name=([^\s]+)\s(.*)\]" to "$2") |

||

| Line 1: | Line 1: | ||

== Description == | == Description == | ||

| − | A thermosetting [ | + | A thermosetting [[amino%20resin|amino resin]] that is made by reacting [[phenol|phenol]] with [[formaldehyde|formaldehyde]]. Discovered in 1907 by Leo Baekeland and sold as [[Bakelite|Bakelite]] in 1909, phenol formaldehyde resin was the first true synthetic plastics. Phenolic resins can be made with either excess formaldehyde (resol) or with an excess of phenol (novolac). Resols are soluble in alcohol while novolacs are solid at room temperature. Both require crosslinking tod form a hard plastic that is brittle but has good resistance to water and biodegradation. In the early 20th century, phenol formaldehyde resins were used for dark color molded plastic products sometimes filled with [[cellulose|cellulose]], [[wood%20flour|wood flour]], or mineral powders. Resol phenolics are currently used for plywood, textile sizing, leather processing, paper strengthening, foams and chemical resistant coatings. Novolacs are used for fibers, adhesives, molded parts, circuit boards, and mechanical fittings. |

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

Revision as of 11:15, 10 May 2016

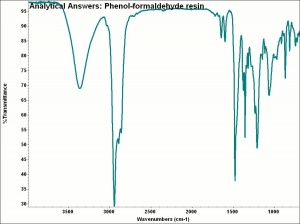

Description

A thermosetting Amino resin that is made by reacting Phenol with Formaldehyde. Discovered in 1907 by Leo Baekeland and sold as Bakelite in 1909, phenol formaldehyde resin was the first true synthetic plastics. Phenolic resins can be made with either excess formaldehyde (resol) or with an excess of phenol (novolac). Resols are soluble in alcohol while novolacs are solid at room temperature. Both require crosslinking tod form a hard plastic that is brittle but has good resistance to water and biodegradation. In the early 20th century, phenol formaldehyde resins were used for dark color molded plastic products sometimes filled with Cellulose, Wood flour, or mineral powders. Resol phenolics are currently used for plywood, textile sizing, leather processing, paper strengthening, foams and chemical resistant coatings. Novolacs are used for fibers, adhesives, molded parts, circuit boards, and mechanical fittings.

Synonyms and Related Terms

phenol-formaldehyde resin (AAT); phenolic resin; PF; novolac; resol; Bakelite

Other Properties

Sensitive to acids and alkalis

| CAS | 9003-35-4 |

|---|

Hazards and Safety

Evolves formaldehyde and ammonia as it degrades. Can corrode copper and brass.

ASIA PACIFIC MICROSPHERES SON: MSDS

Comparisons

General Characteristics of Polymers

Physical Properties for Selected Thermoset Resins

Sources Checked for Data in Record

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 598

- Dictionary of Building Preservation, Ward Bucher, ed., John Wiley & Sons, Inc., New York City, 1996

- Pam Hatchfield, Pollutants in the Museum Environment, Archetype Press, London, 2002

- Thomas C. Jester (ed.), Twentieth-Century Building Materials, McGraw-Hill Companies, Washington DC, 1995

- Sharon Blank, An introduction to plastics and rubbers in collections, Studies in Conservation, 35, 53-63, 1990

- Art and Architecture Thesaurus Online, http://www.getty.edu/research/tools/vocabulary/aat/, J. Paul Getty Trust, Los Angeles, 2000