Difference between revisions of "Hardboard"

| Line 19: | Line 19: | ||

* Easy to cut | * Easy to cut | ||

* Does not hold hails and screws as securely as natural wood | * Does not hold hails and screws as securely as natural wood | ||

| − | |||

==Resources and Citations== | ==Resources and Citations== | ||

| Line 29: | Line 28: | ||

* ''Dictionary of Building Preservation'', Ward Bucher, ed., John Wiley & Sons, Inc., New York City, 1996 | * ''Dictionary of Building Preservation'', Ward Bucher, ed., John Wiley & Sons, Inc., New York City, 1996 | ||

* ''The Dictionary of Paper'', American Paper Institute, New York, Fourth Edition, 1980 | * ''The Dictionary of Paper'', American Paper Institute, New York, Fourth Edition, 1980 | ||

| − | |||

* Pam Hatchfield, ''Pollutants in the Museum Environment'', Archetype Press, London, 2002 | * Pam Hatchfield, ''Pollutants in the Museum Environment'', Archetype Press, London, 2002 | ||

| − | [[Category:Materials database]] | + | [[Category:Materials database]][[Category:MWG]][[Category: Wood]] |

Revision as of 12:21, 9 November 2024

Description

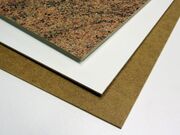

A generic term for man-made wood panel composed of inter-felted lignocellulose fibers consolidated under heat and pressure. A type of Fiberboard, the name hardboard was first used for a stiff board made by hot-pressing waste paper in England in 1898. Later, hardboard was composed of 100% wood fibers obtained from wood chips, sawdust, and board trimmings that are broken into fine particles by grinding (dry process) or by steam (wet process). The interfelted fibers are consolidated with heat and pressure (at least 31 pounds per cubic foot) to form a dense, rigid sheet that is held together by naturally occurring Lignin with no additional adhesive. The dry processed hardboard is smooth on both sides. The wet-process, patented by Masonite Corporation in 1926, forms a higher density fiberboard that is smooth on one side and textured by a wire mesh impression on the other side. Hardboards range from a dark brown to a light tan in color and are very uniform and dense (800-1040 kg/m3). Some hardboards contain a small amount of resin, oil or wax on the surface either as a residual lubricant or as an additive to increase weather resistance. These components may hinder the adherence of paint or Gesso and may be removed with Acetone or Mineral spirits.

Some types of hardwood include:

- Tempered hardwood: Hardboard coated with a thin film of oil and baked; used for construction siding; (such as Tempered Presdwood®)

- Perforated hardboard (pegboard): A tempered hard board with a uniformed array of holes; used for hang items with hooks

- Laminated hardboard: Hardboard covered with veneer of wood, paper, or plastic to improve its appearance; used for furniture and signs; (such as Formica®)

Synonyms and Related Terms

fiberboard. pressed wood; aglomerado de fibras duro (Port.); Masonite® [IPI]; Presdwood® [IPI]; Medex; Medite; Duron® [IPI]; Upson; Homasote; Insulite

Properties

- Any wood product may release organic acids with time.

- Resistant to bugs and dents

- Easy to cut

- Does not hold hails and screws as securely as natural wood

Resources and Citations

- Wikipedia: Hardboard Accessed Oct 2024.

- L.E.Akers, Particle Board and Hardboard. Oxford: Pergamon Press, 1966.

- J.T.Frane, Craftsman's Illustrated Dictionary of Construction Terms. Carlsbad, CA: Craftsman Book 1994.

- A.Katlan, "Early Wood-Fiber Panels: Masonite, Hardboard and Lower-Density Boards" JAIC 33:301-306, 1994.

- Ralph Mayer, A Dictionary of Art Terms and Techniques, Harper and Row Publishers, New York, 1969 (also 1945 printing)

- Dictionary of Building Preservation, Ward Bucher, ed., John Wiley & Sons, Inc., New York City, 1996

- The Dictionary of Paper, American Paper Institute, New York, Fourth Edition, 1980

- Pam Hatchfield, Pollutants in the Museum Environment, Archetype Press, London, 2002