Difference between revisions of "Acrylic fiber"

m (Text replace - "== Authority ==" to "== Sources Checked for Data in Record ==") |

|||

| Line 47: | Line 47: | ||

| − | == | + | == Sources Checked for Data in Record == |

* Hoechst Celanese Corporation, ''Dictionary of Fiber & Textile Technology'' (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990 | * Hoechst Celanese Corporation, ''Dictionary of Fiber & Textile Technology'' (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990 | ||

Revision as of 11:59, 29 April 2016

Description

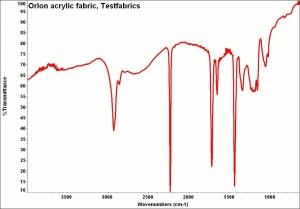

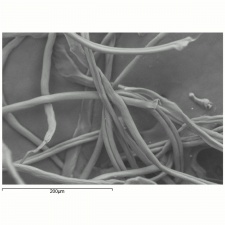

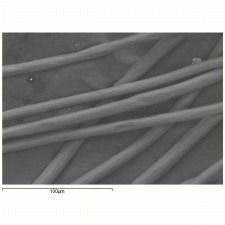

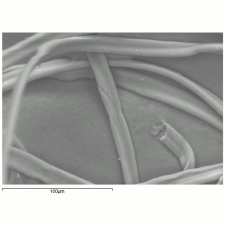

A manufactured fiber in which the fiber-forming substance is any long chain synthetic polymer composed of at least 85% by weight of Acrylonitrile units (Federal Trade Commission definition). Acrylic fibers were first commercially manufactured in 1950 by DuPont as the product Orlon®. The Acrylic resin is dissolved in a solvent, then extruded through spinnerets to produce long, continuous filaments. The smooth, Thermoplastic fibers are resistant to wrinkles, chemicals, UV light, Weathering, insects, Mildew, and moisture. They produce fabrics that are non-allergenic, lightweight, soft, durable and fast drying. They are, however, susceptible to heat and will melt or burn. Acrylic fibers are used for carpets, blankets, drapes, outdoor products (awnings, geotextiles, etc) and apparel such as sweaters, coats, linings, hosiery, dresses, and shirts.

Synonyms and Related Terms

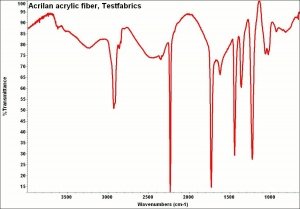

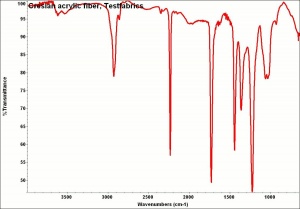

acrylic fibre (Br.); fibra acrílica (Esp.); fibre acrylique (Fr.); acrylaat vezel (Ned); polyacrylonitrile; Orlon® [DuPont]; Creslan® [Sterling]; Zefran® [Badische]; Acrilan® [Solutia]; Dynel® [Union Carbide]; Crylor; Courtelle®; Dralon®;

Other Properties

Insoluble in most common organic solvents. Resistant to weak acids. Burns readily with smoky flame and acid smell. The ash is hard.

Moisture regain = 1.0-3.0% Elongation = 20-55% (dry) Tenacity = 2.0-3.6 g/denier (dry)

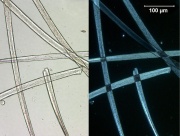

Cross section = variable (dogbone, round, bean shaped or lobed)

| Melting Point | 215-255 (soften) |

|---|---|

| Density | 1.16-1.18 |

Hazards and Safety

Combustible. Accumulates static charge.

Additional Information

° M. Joseph, Introductory Textile Science, Holt Reinhold & Winston, Fort Worth, 1986.

° G.Cook, Handbook of Textile Fibres:II. Man-made Fibres, 5th edition, Merrow Publishing Co., Durham, England, 1984.

Comparisons

Properties of Synthetic Fibers

Sources Checked for Data in Record

- Hoechst Celanese Corporation, Dictionary of Fiber & Textile Technology (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985

- Marjory L. Joseph, Introductory Textile Science, Holt, Rinehart and Winston, Fort Worth, TX, 1986

- J.Gordon Cook, Handbook of Textile Fibres:I Natural Fibres, Merrow Publishing Co. , Durham, England, 1984

- Meredith Montague, contributed information, 1998

- Website address 1 Comment: Fabrics.net : Link