Difference between revisions of "Portland cement"

(username removed) |

|||

| (4 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

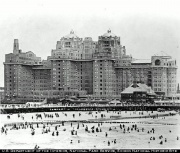

[[File:TraymoreHotel.AC_port.cemt_nps.gov.jpg|thumb|Traymore Hotel]] | [[File:TraymoreHotel.AC_port.cemt_nps.gov.jpg|thumb|Traymore Hotel]] | ||

== Description == | == Description == | ||

| − | + | [[File:Portlandcementwp2.jpg|thumb|Portland cement testing]] | |

| − | A type of hydraulic cement that hardens under water. Portland cement was patented by Joseph Aspdin of Leeds, England in 1824. It was called portland cement because it resembled the grayish colored building stone obtained from the Isle of Portland, England. From 1865, it was imported to the U.S. from England until manufacturing began in 1872 in America. Portland cement is made from limestone mixed with clay then baked in a kiln (1300-1500 C) until it partially vitrifies. The resulting product ([ | + | A type of hydraulic cement that hardens under water. Portland cement was patented by Joseph Aspdin of Leeds, England in 1824. It was called portland cement because it resembled the grayish colored building stone obtained from the Isle of Portland, England. From 1865, it was imported to the U.S. from England until manufacturing began in 1872 in America. Portland cement is made from limestone mixed with clay then baked in a kiln (1300-1500 C) until it partially vitrifies. The resulting product ([[calcium%20silicate|calcium silicate]]) is powdered for use as a cement. Portland cement sets to a hard impermeable solid when mixed with water. Analysis indicates that the cement contained 60-64% [[lime]], 20-24% [[silica]], 6-10% [[alumina]], and 3-5% [[ferric%20oxide|iron oxide]], with small amounts of [[magnesia]], [[sodium]], [[potassium]], and [[sulfur]]. Portland cement is often mixed with aggregated to form mortar and concrete. It is resistant to water and has been used as a fill for large voids in outdoor sculptures (Thornton, 1988). Portland cement has been used for skyscrapers, dams, bridges, roads, and other structures. |

Currently, in the U.S. five types of portland cement are standardized by the American Society for Testing and Materials (ASTM): | Currently, in the U.S. five types of portland cement are standardized by the American Society for Testing and Materials (ASTM): | ||

| − | + | * Type I (ordinary): used in general construction such as sidewalks | |

| − | + | * Type II (modified -omitted in other countries): used near water such as sea walls and building foundations | |

| − | + | * Type III (high-early-strength or rapid hardening): used in cold-weather construction | |

| − | + | * Type IV (low-heat): used for massive structures such as dams | |

| − | + | * Type V (sulfate-resistant or Ferrari cement): used for foundation in high sulfate soils. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

| − | ciment Portland (Fr.); cimento Portland (Port.); hydraulic cement; water cement; portland concrete (sp) | + | ciment Portland (Fr.); cimento Portland (Port.); hydraulic cement; water cement; portland concrete (sp); CAS = 65997-15-1 |

| − | + | == Risks == | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Skin contact may cause irritation | Skin contact may cause irritation | ||

| − | == | + | ==Resources and Citations== |

| − | + | * J.Thornton, "A Brief History and Review of the Early Practice and Materials of Gap-Filling in the West" JAIC 37: 3-22, 1998. | |

| − | J.Thornton, "A Brief History and Review of the Early Practice and Materials of Gap-Filling in the West" JAIC 37: 3-22, 1998. | ||

| − | |||

| − | |||

* R. J. Gettens, G.L. Stout, ''Painting Materials, A Short Encyclopaedia'', Dover Publications, New York, 1966 | * R. J. Gettens, G.L. Stout, ''Painting Materials, A Short Encyclopaedia'', Dover Publications, New York, 1966 | ||

| Line 51: | Line 37: | ||

* ''Dictionary of Building Preservation'', Ward Bucher, ed., John Wiley & Sons, Inc., New York City, 1996 | * ''Dictionary of Building Preservation'', Ward Bucher, ed., John Wiley & Sons, Inc., New York City, 1996 | ||

| − | * Art and Architecture Thesaurus Online, | + | * Art and Architecture Thesaurus Online, https://www.getty.edu/research/tools/vocabulary/aat/, J. Paul Getty Trust, Los Angeles, 2000 Comment: small 'p' is preferred term |

* ''The Dictionary of Art'', Grove's Dictionaries Inc., New York, 1996 Comment: "Concrete" | * ''The Dictionary of Art'', Grove's Dictionaries Inc., New York, 1996 Comment: "Concrete" | ||

Latest revision as of 11:03, 20 August 2022

Description

A type of hydraulic cement that hardens under water. Portland cement was patented by Joseph Aspdin of Leeds, England in 1824. It was called portland cement because it resembled the grayish colored building stone obtained from the Isle of Portland, England. From 1865, it was imported to the U.S. from England until manufacturing began in 1872 in America. Portland cement is made from limestone mixed with clay then baked in a kiln (1300-1500 C) until it partially vitrifies. The resulting product (Calcium silicate) is powdered for use as a cement. Portland cement sets to a hard impermeable solid when mixed with water. Analysis indicates that the cement contained 60-64% Lime, 20-24% Silica, 6-10% Alumina, and 3-5% iron oxide, with small amounts of Magnesia, Sodium, Potassium, and Sulfur. Portland cement is often mixed with aggregated to form mortar and concrete. It is resistant to water and has been used as a fill for large voids in outdoor sculptures (Thornton, 1988). Portland cement has been used for skyscrapers, dams, bridges, roads, and other structures.

Currently, in the U.S. five types of portland cement are standardized by the American Society for Testing and Materials (ASTM):

- Type I (ordinary): used in general construction such as sidewalks

- Type II (modified -omitted in other countries): used near water such as sea walls and building foundations

- Type III (high-early-strength or rapid hardening): used in cold-weather construction

- Type IV (low-heat): used for massive structures such as dams

- Type V (sulfate-resistant or Ferrari cement): used for foundation in high sulfate soils.

Synonyms and Related Terms

ciment Portland (Fr.); cimento Portland (Port.); hydraulic cement; water cement; portland concrete (sp); CAS = 65997-15-1

Risks

Skin contact may cause irritation

Resources and Citations

- J.Thornton, "A Brief History and Review of the Early Practice and Materials of Gap-Filling in the West" JAIC 37: 3-22, 1998.

- R. J. Gettens, G.L. Stout, Painting Materials, A Short Encyclopaedia, Dover Publications, New York, 1966

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: p. 455

- Ralph Mayer, A Dictionary of Art Terms and Techniques, Harper and Row Publishers, New York, 1969 (also 1945 printing)

- Richard S. Lewis, Hawley's Condensed Chemical Dictionary, Van Nostrand Reinhold, New York, 10th ed., 1993

- Walter C. McCrone, John Gustave Delly, The Particle Atlas, W. McCrone Associates, Chicago, IV, 1972

- Susan E. Schur, Conservation Terminology: A review of Past & Current Nomenclature of Materials, Technology and Conservation, Spring (p.34-39); Summer (p.35-38); Fall (p.25-36), 1985

- Dictionary of Building Preservation, Ward Bucher, ed., John Wiley & Sons, Inc., New York City, 1996

- Art and Architecture Thesaurus Online, https://www.getty.edu/research/tools/vocabulary/aat/, J. Paul Getty Trust, Los Angeles, 2000 Comment: small 'p' is preferred term

- The Dictionary of Art, Grove's Dictionaries Inc., New York, 1996 Comment: "Concrete"