Difference between revisions of "Polystyrene"

| (11 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | [[ | + | [[File:2006.139-SC177413.jpg|thumb|Ebendorf Necklace<br>MFA #:2006.139]] |

== Description == | == Description == | ||

| + | [[File:Pitcher 2010578.jpg|thumb|Plastic pitcher<br>MFA# 2010.578]] | ||

| + | A thermoplastic polyolefin made from styrene with a general composition of [-C6H5CHCH2-]n. Although probably known earlier, polystyrene was described in 1839 by E. Simon of Germany, after he watched the clear [[styrene|styrene]] liquid distilled from [[storax (resin)|storax]] resin cool then harden to form a solid mass. Polystyrene was first commercially made in 1929 by I.G. Farben (Germany) for use in [[styrene-butadiene%20rubber|styrene butadiene]] synthetic rubbers. Polystyrene is a hard, strong solid with good dimensional stability and impact resistance; it can be molded and fabricated. Polystyrene is often prepared as an expanded foam ([[Styrofoam|Styrofoam®]]) using blowing agents for use in temperature and sound insulation. It can be co-polymerized with many other polymers for increased flexibility, i.e. [[ABS |ABS rubbers]] are made from [[acrylonitrile]], [[butadiene]], and styrene. | ||

| − | + | Examples include: | |

| − | + | {| class="wikitable" style="text-align:center" | |

| + | ! Polystyrene Forms !! Uses!! Products | ||

| + | |- | ||

| + | !Extruded Foam, Closed Cell | ||

| + | |Container, Padding, Packing | ||

| + | |Dow Chemical: Styrofoam | ||

| + | <br>Gilman Bros.: Stylite, Cellulite | ||

| + | |- | ||

| + | !Polystyrene core laminated with paper or plastic on both sides | ||

| + | |Support, Backing | ||

| + | |3A Composites: Fome-Cor | ||

| + | <br>Bainbridge: Artcare Foam Core Boards & Artcare Restore | ||

| + | <br>Laird Plastics: Gatorboard | ||

| + | |- | ||

| + | !Expanded polystyrene foam | ||

| + | |Loose-fill molded pieces | ||

| + | |patented Dow Chemical: Packing peanuts (packing noodles, foam popcorn) | ||

| + | |- | ||

| + | |} | ||

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

| + | PS; styrene polymer; polystyrène (Fr.); poliestireno (Esp.); polistirene (It.); poliestireno (Port.); styrene resin | ||

| − | + | Examples: Styrofoam® [Dow]; Luran; Styron; Lustrex; [[Fome-Cor|Fome-Cor®]]; Algil [Polymers, Inc.]; Permene [Modglin Co.]; Shalon [Polymers, Inc.]; Polyfil [Mack Molding]; Durastran; Plexene | |

| − | |||

==Applications== | ==Applications== | ||

* Foam, peanuts | * Foam, peanuts | ||

| Line 42: | Line 62: | ||

[[media:download_file_359.pdf|Physical Properties for Selected Thermoplastic Resins]] | [[media:download_file_359.pdf|Physical Properties for Selected Thermoplastic Resins]] | ||

| − | |||

| − | |||

== Sources Checked for Data in Record == | == Sources Checked for Data in Record == | ||

<references/> | <references/> | ||

| + | * Contributions: Gina Watkinson, AIC Plastics Panel, 2020. | ||

* ''The American Heritage Dictionary'' or ''Encarta'', via Microsoft Bookshelf 98, Microsoft Corp., 1998 | * ''The American Heritage Dictionary'' or ''Encarta'', via Microsoft Bookshelf 98, Microsoft Corp., 1998 | ||

| Line 71: | Line 90: | ||

* Sharon Blank, An introduction to plastics and rubbers in collections, ''Studies in Conservation'', 35, 53-63, 1990 Comment: used in synthetic rubbers since 1927... it was first used as polystyrene in the mid 1930s | * Sharon Blank, An introduction to plastics and rubbers in collections, ''Studies in Conservation'', 35, 53-63, 1990 Comment: used in synthetic rubbers since 1927... it was first used as polystyrene in the mid 1930s | ||

| − | * Art and Architecture Thesaurus Online, | + | * Art and Architecture Thesaurus Online, https://www.getty.edu/research/tools/vocabulary/aat/, J. Paul Getty Trust, Los Angeles, 2000 |

* History of Plastics www.nswpmith.com.au/historyofplastics.html Comments:In Europe, I.G.Farbenindustrie: experiments 1924, production 1929 In US, Dow Chemical: experiments before 1930, production 1937 | * History of Plastics www.nswpmith.com.au/historyofplastics.html Comments:In Europe, I.G.Farbenindustrie: experiments 1924, production 1929 In US, Dow Chemical: experiments before 1930, production 1937 | ||

Latest revision as of 10:02, 18 October 2022

Description

A thermoplastic polyolefin made from styrene with a general composition of [-C6H5CHCH2-]n. Although probably known earlier, polystyrene was described in 1839 by E. Simon of Germany, after he watched the clear Styrene liquid distilled from storax resin cool then harden to form a solid mass. Polystyrene was first commercially made in 1929 by I.G. Farben (Germany) for use in styrene butadiene synthetic rubbers. Polystyrene is a hard, strong solid with good dimensional stability and impact resistance; it can be molded and fabricated. Polystyrene is often prepared as an expanded foam (Styrofoam®) using blowing agents for use in temperature and sound insulation. It can be co-polymerized with many other polymers for increased flexibility, i.e. ABS rubbers are made from Acrylonitrile, Butadiene, and styrene.

Examples include:

| Polystyrene Forms | Uses | Products |

|---|---|---|

| Extruded Foam, Closed Cell | Container, Padding, Packing | Dow Chemical: Styrofoam

|

| Polystyrene core laminated with paper or plastic on both sides | Support, Backing | 3A Composites: Fome-Cor

|

| Expanded polystyrene foam | Loose-fill molded pieces | patented Dow Chemical: Packing peanuts (packing noodles, foam popcorn) |

Synonyms and Related Terms

PS; styrene polymer; polystyrène (Fr.); poliestireno (Esp.); polistirene (It.); poliestireno (Port.); styrene resin

Examples: Styrofoam® [Dow]; Luran; Styron; Lustrex; Fome-Cor®; Algil [Polymers, Inc.]; Permene [Modglin Co.]; Shalon [Polymers, Inc.]; Polyfil [Mack Molding]; Durastran; Plexene

Applications

- Foam, peanuts

- Transparent enclosures, containers

- Inexpensive rigid plastics: disposable cutlery, cabinets, furniture

- Foam boards, insulation

Personal Risks

Aldrich Chemical: MSDS

Collection Risks

- Degrades in UV radiation and light which causes yellowing and embrittlement.[1]

- Photo-oxidation increases “Plasticizers exuding from PVC are very good solvents and can dissolve polystyrene boxes.” [2]

- Polystyrene carries a static charge and attracts dust.

- Poor shock absorber.

Environmental Risks

Physical and Chemical Properties

- Chemically stable at room temperature [1]

- Attacked by hydrocarbon solvents, oils, ketones, esters, inorganic acids.

- Resistant to organic acids, alkalis, alcohols.

- Shrinks in boiling water [2]

- Burns with luminous smoky flame giving faint odor of marigolds.

- CAS = 9003-53-6

- Melting Point = softens about 150C

- Density = 1.060

- Refractive Index = 1.59

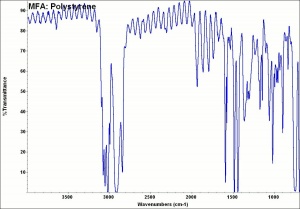

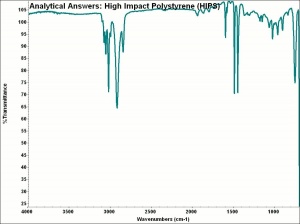

Comparisons

General Characteristics of Polymers

Physical Properties for Selected Thermoplastic Resins

Sources Checked for Data in Record

- ↑ 1.0 1.1 Shashoua, Yvonne. Conservation of Plastics: Materials Science, Degradation and Preservation. Amsterdam etc.: Elsevier, 2008. 248

- ↑ 2.0 2.1 Scott R. Williams. Plastic Storage Products. In ‘Preventive Conservation: Collection Storage’ Lisa Elkin and Christopher A. Norris (eds.), Society for the Preservation of Natural History Collections, New York. 2019. 774

- Contributions: Gina Watkinson, AIC Plastics Panel, 2020.

- The American Heritage Dictionary or Encarta, via Microsoft Bookshelf 98, Microsoft Corp., 1998

- R. J. Gettens, G.L. Stout, Painting Materials, A Short Encyclopaedia, Dover Publications, New York, 1966 Comment: ref.index= 1.50-1.75

- G.S.Brady, Materials Handbook, McGraw-Hill Book Co., New York, 1971 Comment: ref. index = 1.59

- Dictionary of Building Preservation, Ward Bucher, ed., John Wiley & Sons, Inc., New York City, 1996

- Theodore J. Reinhart, 'Glossary of Terms', Engineered Plastics, ASM International, 1988

- Lynda A. Zycherman, J.Richard Schrock, A Guide to Museum Pest Control, FAIC and Association of Systematics Collections, Washington DC, 1988

- R.D. Harley, Artists' Pigments c. 1600-1835, Butterworth Scientific, London, 1982

- Pam Hatchfield, Pollutants in the Museum Environment, Archetype Press, London, 2002

- Thomas C. Jester (ed.), Twentieth-Century Building Materials, McGraw-Hill Companies, Washington DC, 1995

- M.Kaufman, The First Century of Plastics, The Plastics and Rubber Institute, London, 1963 Comment: first developed commercially in 1930

- F. Kidd, Brushmaking Materials, Bristish Brush Manufacturers, London, 1957

- Sharon Blank, An introduction to plastics and rubbers in collections, Studies in Conservation, 35, 53-63, 1990 Comment: used in synthetic rubbers since 1927... it was first used as polystyrene in the mid 1930s

- Art and Architecture Thesaurus Online, https://www.getty.edu/research/tools/vocabulary/aat/, J. Paul Getty Trust, Los Angeles, 2000

- History of Plastics www.nswpmith.com.au/historyofplastics.html Comments:In Europe, I.G.Farbenindustrie: experiments 1924, production 1929 In US, Dow Chemical: experiments before 1930, production 1937