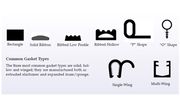

Gasket types, generic

Description

For further information, please see AIC wiki Gaskets for Exhibit Cases

A compressible material used in an interface to reduce gaps and create tighter fitting joints. Gaskets are held under pressure to reduce leakage, transmission, and or vibration. As such, in museums, gaskets can be used to minimize air exchange between sealed cases and museums, to compensate for alignment irregularities between two edges, and to reduce potential for the transfer of dust, dirt, pollutants and pests. In the past, Natural rubber, Paper, Metal, Felt, Asbestos, and Cork were used for gaskets. More recently, synthetic options, called elastomers have become available. While this record is named 'Gasket', elastomers are also used as spacers, washers, shims and seals. Some commercial products are filled with glass spheres, silica, graphite, pigments and other materials

Examples of some elastomers include:

| Material | Durometer Shore A (hardness) | General properties | Advantages | Disadvantages | Commercial names |

|---|---|---|---|---|---|

| Polyethylene (LDPE, HDPE) | 50-60 | Exceptional shock absorption and cushioning; strong, lightweight, closed cell, impact resistant, lightweight, low moisture absorption, high tensile strength, nontoxic, recyclable | Water repellant; resistant to most solvents; inert to biological attack | Emits some methane and ethylene | Climaloc, Ethafoam; Magic Foam Cord; Plastazote; Volara; Zotefoam |

| Polypropylene (EPP) | Lightweight flexible; excellent thermal insulation; readily resumes its original shape; absorbs impacts without breaking, recyclable | Resists moisture and chemicals | Poor resistance to UV and high temperatures; not recommended for outdoor use | Propafoam; Propazote; Polyzote; Microfoam; Strandfoam | |

| Ethylene propylene diene monomer (EPDM) | 30-90 | Excellent resistant to ultraviolet light, ozone, oxidants, heat, and compression set , economical, good durability | Resists the swelling effects of polar chemicals, animal and vegetable oils. | Mineral oils and solvents, aromatic hydrocarbons | Santoprene |

| Ethylene vinyl acetate closed-cell elastomeric seal (EVA) | Lightweight, odorless with good flexibility and softness; good durability; easy to work with, can be shaped by heat | Excellent UV, ozone and chemical resistance. Good acoustic properties | low resistance to heat and solvents; can give off vinegar odor | not generally used in museums | |

| Fluorocarbon elastomer | 50-95 | Excellent fluid resistance. Work well at low temperatures. | Very good chemical resistance to acids and oils as well as hydrocarbon and halogenated solvents | Ketones, low molecular weight esters and nitro-containing hydrocarbons. | Viton, FKM |

| Isoprene (butyl rubber) | 40-80 | Excellent resistance to heat, oxygen and water. | Low gas permeation. High vibration absorption (dampening) | Hydrocarbons solvents and oils | |

| Nitrile rubber (NBR, Buna-N) | 20-100 | Good physical properties; stong and durable with broad temperature range. | Resistant to water, solvents, petroleums and oils | Attacked by ozone and chlorinated solvents | Krynac |

| Polychloroprene | 15-95 | Good weathering, flame retardant. High tensile and tear strength | Moderate chemicals and acids, ozone, oils fats, greases and many solvents. | Strong oxidizing acids, esters, ketones, chlorinated, aromatic and nitro hydrocarbons | Neoprene |

| Polytetrafluoroethylene (PTFE) | 73 | Good electrical insulator. Inflammable and stable to light. Inert, often used in drug and food contact | Hydrophobic and very resistant to all solvents, acids, and bases | Low strength and susceptible to creep at room temperature. Does not return to pre-compression position | Teflon |

| Silicone rubber (dimethyl silicone) | 50-70 | Most stable of all elastomers; will bounce back even after long compression. No odor or taste. | Resistant to high and low temperature ranges, fatigue, most chemicals, oils, oxygen, and ozone | Poor resistance to aromatic solvents. May have residual silicone oil that creeps to other surfaces. | |

| Styrene butadiene (SBR, Buna-S) | 40-100 | Low cost, general purpose elastomer. Excellent flex and strength | Resistant to alcohols and ketones | Petroleum based fluids | |

| Nylon (polyamide) | Lightweight, tough, strong, very durable; resistant to chemicals, does not absorb gases or water; can be used outdoors | Nomex; ZotekNB-50; Polyamide NB; | |||

| Chloroprene | Closed cell is water proof, less compressible and more expensive; Open cell is breathable. | Both types are inert, flame resistant, and durable with excellent resistance to water, oils, and chemicals. | Has potential for causing allergic reactions; attacked by most acids and organic solvents | Duprene; Neoprene | |

| Polystyrene, expanded (EPS) or extruded (XPS) | EPS is friable and breaks easily; good thermal insulators, easy to cut; XPS is stiffer, both dimensionally stable; inexpensive, not recyclable | water resistant but not water-proof | Sunlight can cause bleaching and degradation; some products use halogenated products that are toxic and/or may corrode metal | not recommended for use in museums | |

| Polyurethane foam (PU-F) | Wide variety of densities; commonly used for indoor products; often filled to improve mechanical strength | Deterioration accelerated by UV and water; usually contains flame retardants (Al hydroxides or halogenated compounds); may fog | not recommended for use in museums | ||

| Polyvinyl chloride (PVC, vinyl) | Resistant to water and abrasion; rigid; easily cut; can be shaped with heat; | Heat can release noxious fumes; does not fully spring back when compressed | not recommended for use in museums | ||

| Magnetic gaskets | 79-80 | A silicone rubber gasket filled with magnetite. Can be molded and extruded as needed | Elastosil R781 (Wacker) |

Resources and Citations

- Jean Tetreault Products Used in Preventive Conservation CCI, December 2017. Link

- Blaylock Gasket and Packing: Comparison table